[ad_1]

Thirty years in the past, a botanist in Germany had a easy want: to see the inside workings of woody crops with out dissecting them. By bleaching away the pigments in plant cells, Siegfried Fink managed to create clear wooden, and he revealed his method in a distinct segment wooden know-how journal. The 1992 paper remained the final phrase on see-through wooden for greater than a decade, till a researcher named Lars Berglund stumbled throughout it.

Berglund was impressed by Fink’s discovery, however not for botanical causes. The supplies scientist, who works at KTH Royal Institute of Technology in Sweden, makes a speciality of polymer composites and was curious about making a extra strong different to clear plastic. And he wasn’t the one one curious about wooden’s virtues. Across the ocean, researchers on the University of Maryland had been busy on a associated aim: harnessing the power of wooden for nontraditional functions.

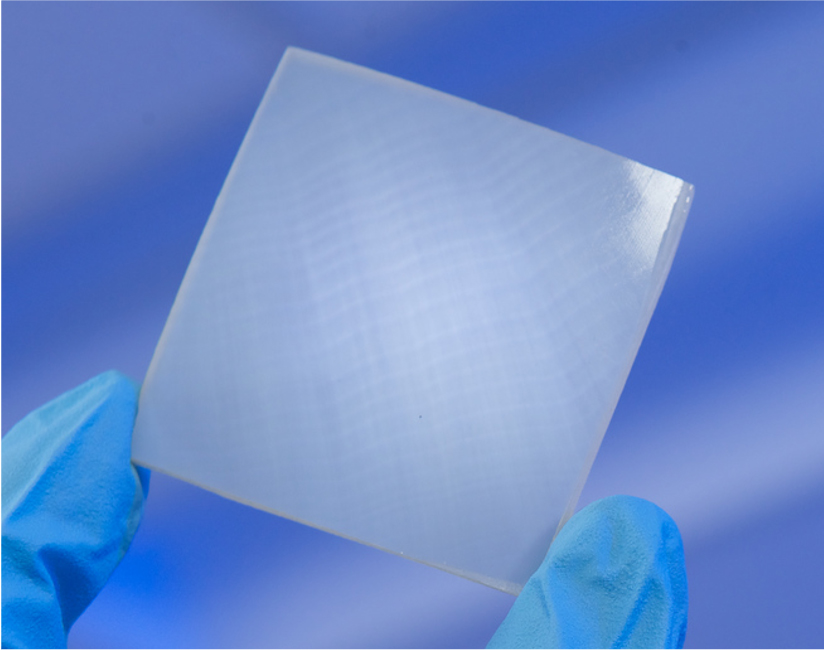

Now, after years of experiments, the analysis of those teams is beginning to bear fruit. Transparent wooden may quickly discover makes use of in super-strong screens for smartphones; in comfortable, glowing lighting fixtures; and whilst structural options, resembling color-changing home windows.

“I truly believe this material has a promising future,” says Qiliang Fu, a wooden nanotechnologist at Nanjing Forestry University in China who labored in Berglund’s lab as a graduate pupil.

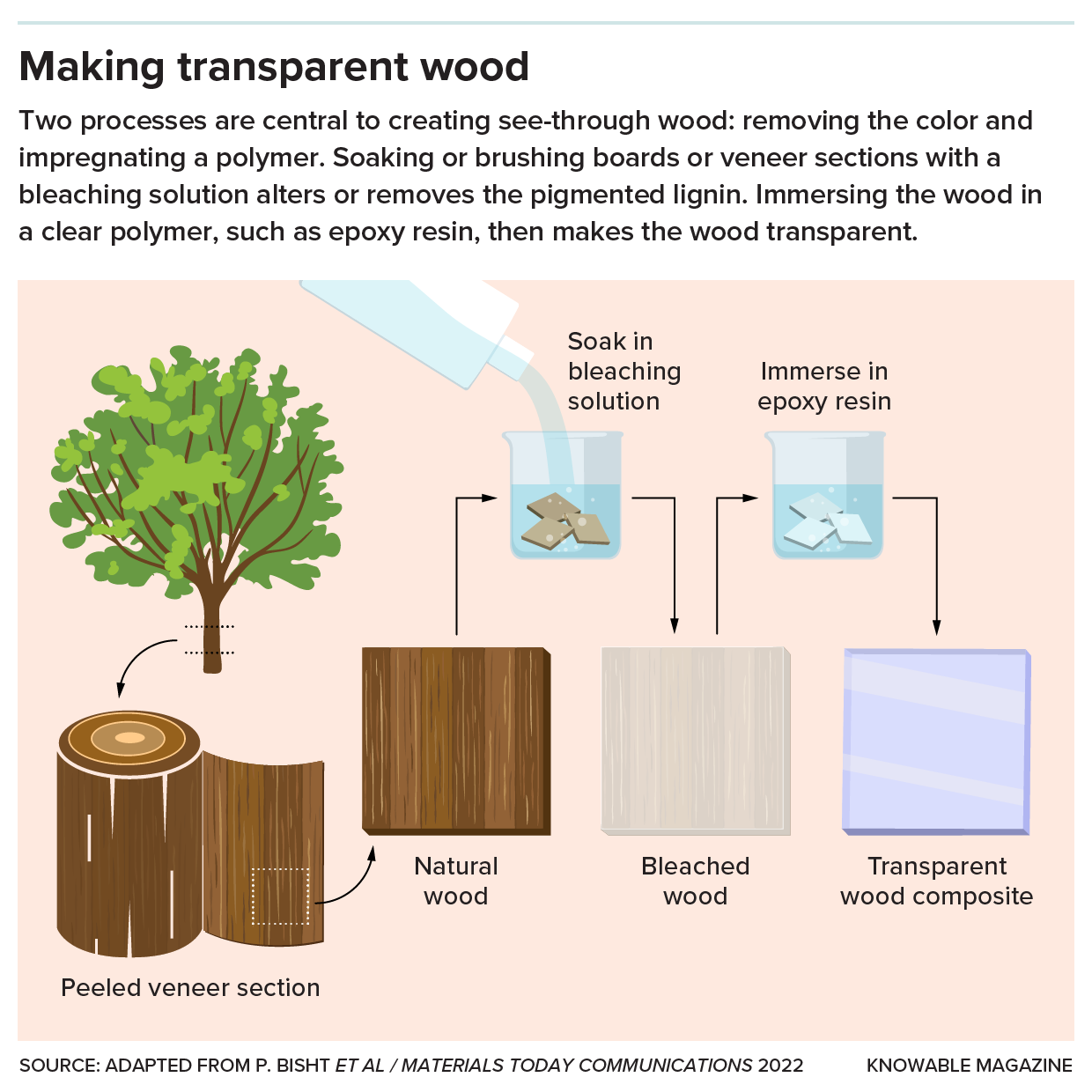

Wood is made up of numerous little vertical channels, like a good bundle of straws sure along with glue. These tube-shaped cells transport water and vitamins all through a tree, and when the tree is harvested and the moisture evaporates, pockets of air are left behind. To create see-through wooden, scientists first want to switch or do away with the glue, known as lignin, that holds the cell bundles collectively and offers trunks and branches with most of their earthy brown hues. After bleaching lignin’s shade away or in any other case eradicating it, a milky-white skeleton of hole cells stays.

This skeleton remains to be opaque, as a result of the cell partitions bend gentle to a special diploma than the air within the cell pockets does—a worth known as a refractive index. Filling the air pockets with a substance like epoxy resin that bends gentle to an analogous diploma to the cell partitions renders the wooden clear.

The materials the scientists labored with is skinny—usually lower than a millimeter to round a centimeter thick. But the cells create a sturdy honeycomb construction, and the tiny wooden fibers are stronger than the perfect carbon fibers, says supplies scientist Liangbing Hu, who leads the analysis group engaged on clear wooden on the University of Maryland in College Park. And with the resin added, clear wooden outperforms plastic and glass: In assessments measuring how simply supplies fracture or break beneath strain, clear wooden got here out round thrice stronger than clear plastics like Plexiglass and about 10 occasions harder than glass.

“The results are amazing, that a piece of wood can be as strong as glass,” says Hu, who highlighted the options of clear wooden within the 2023 Annual Review of Materials Research.

The course of additionally works with thicker wooden however the view via that substance is hazier as a result of it scatters extra gentle. In their authentic research from 2016, Hu and Berglund each discovered that millimeter-thin sheets of the resin-filled wooden skeletons let via 80 to 90 p.c of sunshine. As the thickness will get nearer to a centimeter, gentle transmittance drops: Berglund’s group reported that 3.7-millimeter-thick wooden—roughly two pennies thick—transmitted solely 40 p.c of sunshine.

The slim profile and power of the fabric means it might be an important different to merchandise constituted of skinny, simply shattered cuts of plastic or glass, resembling show screens. The French firm Woodoo, for instance, makes use of an analogous lignin-removing course of in its wooden screens, however leaves a little bit of lignin to create a special shade aesthetic. The firm is tailoring its recyclable, touch-sensitive digital shows for merchandise together with automobile dashboards and promoting billboards.

But most analysis has centered on clear wooden as an architectural characteristic, with home windows a very promising use, says Prodyut Dhar, a biochemical engineer on the Indian Institute of Technology Varanasi. Transparent wooden is a much better insulator than glass, so it may assist buildings retain warmth or preserve it out. Hu and colleagues have additionally used polyvinyl alcohol, or PVA—a polymer utilized in glue and meals packaging—to infiltrate the wooden skeletons, making clear wooden that conducts warmth at a price 5 occasions decrease than that of glass, the workforce reported in 2019 in Advanced Functional Materials.

And researchers are developing with different tweaks to extend wooden’s potential to carry or launch warmth, which might be helpful for energy-efficient buildings. Céline Montanari, a supplies scientist at RISE Research Institutes of Sweden, and colleagues experimented with phase-change supplies, which flip from storing to releasing warmth after they change from stable to liquid, or vice-versa. By incorporating polyethylene glycol, for instance, the scientists discovered that their wooden may retailer warmth when it was heat and launch warmth because it cooled, work they revealed in ACS Applied Materials and Interfaces In 2019.

Transparent wooden home windows would due to this fact be stronger and help in temperature management higher than conventional glass, however the view via them could be hazy, extra much like frosted glass than an everyday window. However, the haziness might be a bonus if customers need diffuse gentle: Since thicker wooden is robust, it might be {a partially} load-bearing gentle supply, Berglund says, probably appearing as a ceiling that gives comfortable, ambient gentle to a room.

Hu and Berglund have continued to toy with methods to bestow new properties on clear wooden. Around 5 years in the past, Berglund and colleagues at KTH and Georgia Institute of Technology discovered they might mimic good home windows, which may swap from clear to tinted to dam visibility or the solar’s rays. The researchers sandwiched an electrochromic polymer—a substance that may change shade with electrical energy—between layers of clear wooden coated with an electrode polymer to conduct electrical energy. This created a pane of wooden that modifications from clear to magenta when customers run a small electrical present via it.

More lately, the 2 teams have shifted their consideration to enhancing the sustainability of clear wooden manufacturing. For instance, the resin used to fill the wooden scaffolding is often a petroleum-derived plastic product, so it’s higher to keep away from utilizing it, Montanari says. As a substitute, she and colleagues invented a completely bio-based polymer, derived from citrus peels. The workforce first mixed acrylic acid and limonene, a chemical extracted from lemon and orange rinds that’s present in important oils. Then they impregnated delignified wooden with it. Even with a fruity filling, the bio-based clear wooden maintained its mechanical and optical properties, withstanding round 30 megapascals of strain greater than common wooden and transmitting round 90 p.c of sunshine, the researchers reported in 2021 in Advanced Science.

Hu’s lab, in the meantime, lately reported in Science Advances a greener lignin-bleaching methodology that leans on hydrogen peroxide and UV radiation, additional lowering the power calls for of manufacturing. The workforce brushed wooden slices starting from about 0.5 to three.5 millimeters in thickness with hydrogen peroxide, then left them in entrance of UV lamps to imitate the solar’s rays. The UV bleached away the pigment-containing components of lignin however left the structural components intact, thus serving to to retain extra power within the wooden.

These extra environmentally pleasant approaches assist restrict the quantity of poisonous chemical substances and fossil-based polymers utilized in manufacturing, however for now, glass nonetheless has decrease end-of-life environmental impacts than clear wooden, in line with an evaluation by Dhar and colleagues in Science of the Total Environment. Embracing greener manufacturing schemes and scaling up manufacturing are two steps needed so as to add clear wooden to mainstream markets, researchers say, however it should take time. However, they’re assured it may be completed and imagine in its potential as a sustainable materials.

“When you’re trying to achieve sustainability, you don’t only want to match the properties of fossil-based materials,” Montanari says. “As a scientist, I want to surpass this.”

This article initially appeared in Knowable Magazine, an impartial journalistic endeavor from Annual Reviews. Sign up for the newsletter.