[ad_1]

News briefs for the week check out AMRs readying to tackle Antarctic chilly, John Deere’s transfer into precision farming with ExactShot autonomous planter, Cobalt Robotics fielding safety patrols for Johnson Controls’ mega-size properties, and specialised cobot arm with glass finish effector is a breakthrough improve for biopsies and different subdermal procedures.

Mobile robotic takes on excessive chilly

Winter arrives in August for Antarctica, the place temperatures at distant elements of the excessive plateau could usually drop beneath -90°C (-130°F). Summer begins in January for Antarctica, the place the times common 6° C (43°F). Downright balmy.

Can autonomous cellular robots (AMRs) function in such extremes of climate? An AMR appropriately named Ice Cube was constructed to search out out. As a check monitor, the newly-launched Ice Cube is being examined within the Norwegian Arctic, the place in Karasjok winter temperatures (in January) have slumped as little as −51.4 °C (−60.5 °F).

It’s definitely not the extremes of Antarctica, however nonetheless mighty chilly. The common human can solely survive -49 levels F (-45 levels C) for about thirty minutes. Hence, a giant cause why an AMR like Ice Cube is so vital.

It’s definitely not the extremes of Antarctica, however nonetheless mighty chilly. The common human can solely survive -49 levels F (-45 levels C) for about thirty minutes. Hence, a giant cause why an AMR like Ice Cube is so vital.

“We can check quite a lot of issues in our lab, however not how the rover drives within the snow, how the photo voltaic panels deal with the snow and temperatures, and the way chilly it is going to get contained in the rover and the way shortly it turns into very chilly,” explains group supervisor Laurenz Edelmann of Eindhoven University of Technology within the Netherlands, the place Ice Cube was constructed.

Team Polar, as Edelmann’s group is known as, need to create an alternate solution to do in depth environmental analysis within the coldest locations on our planet by growing an unmanned rover.

The group started researching and constructing in 2018, and now, 4 years on, has its first working prototype working in Trondheim, Norway. Winter: -15.0°F (-26.1°C).

According to Team Polar: “Earth is dealing with its greatest downside in centuries: local weather change. To fight it, we have to higher perceive the elements behind local weather change. It is then essential to gather details about our planet in locations the place nature continues to be pristine, and roughly untouched by local weather change.”

ExactShot saves work, cash, and the atmosphere

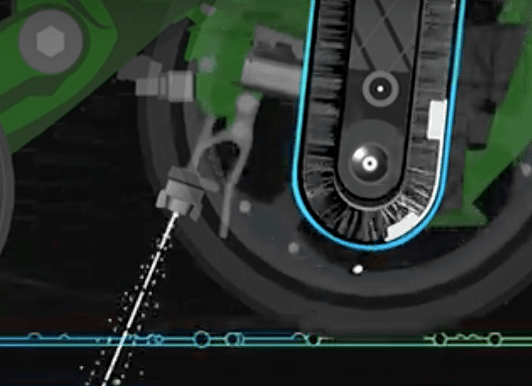

When planting, starter fertilizer is crucial in making new seedings flourish. However, farmers use an excessive amount of when making use of a steady movement of fertilizer to all the row of seeds. John Deere’s newly-released ExactShot is a robotics-based fertilizer system that  applies solely exact quantities of starter.

applies solely exact quantities of starter.

“What ExactShot enables us to do is actually deliver starter fertilizer exactly where the seed is at,” says Madelyn Koester, senior product supervisor and soil well being lead at John Deere. “We actually reduce our fertilizer application by about 60% with this new system, which has huge cost savings for the farmer, but also has a huge environmental impact, because we’re putting that much less fertilizer out, which reduces the chances for runoff and other things that are negatively impacting the environment.”

The key to the system: ExactShot know-how makes use of sensors and robotics to ship out timed bursts of fertilizer that coat particular person seeds, leaving the areas between them fertilizer-free. (see video)

The key to the system: ExactShot know-how makes use of sensors and robotics to ship out timed bursts of fertilizer that coat particular person seeds, leaving the areas between them fertilizer-free. (see video)

“Precision is vital in agriculture as a result of we’re working in enormous portions of acres and vegetation per acre,” mentioned Deanna Kovar, John Deere’s vice chairman of manufacturing and precision agriculture manufacturing techniques. “Eventually, we are going to literally deal with each plant on an acre of a area in another way based mostly on what we’re studying by our laptop imaginative and prescient and machine-learning tech.”

Cobot arm spurs growth of glass finish effector

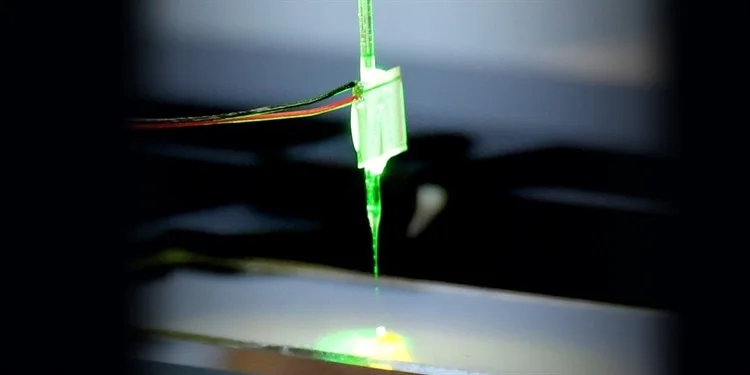

The medical hypodermic needle, used over 16 billion occasions yearly, has not modified in 150 years. Piercing the pores and skin and both  injecting or withdrawing physique fluids is its major operate. However, the system has confirmed itself to be inefficient when used for biopsy, which is a “procedure to remove a piece of tissue or a sample of cells from a body so that it can be tested in a laboratory.”

injecting or withdrawing physique fluids is its major operate. However, the system has confirmed itself to be inefficient when used for biopsy, which is a “procedure to remove a piece of tissue or a sample of cells from a body so that it can be tested in a laboratory.”

For biopsies, when the hypodermic needle is used to supply histological and molecular tissue samples, as much as 34% of histological and as much as 50% molecular assessments fail or the harvests present inadequate pattern portions.

In a breakthrough for microfluidics, scientists at ETH Zurich (Switzerland) have developed a skinny glass needle (finish effector) that may be affixed to a novel cobot arm with 5-DoF. Ultrasonic oscillations of the glass needle permit medical personnel to pump and blend small quantities of liquid and entice particles for biopsies that in any other case can be inadequate for testing. Particles transfer towards the oscillating glass needle, the place they have a tendency to build up.

ETH Professor Daniel Ahmed and his group are at present “integrating traditional microfluidics and robotics.” Making use of ultrasound, the system is “ideal for executing an extensive range of tasks in microfluidic and micro-robotic applications.”

Cobalt’s robotic guards on the job at Johnson Controls

Johnson Controls’ company actual property division, Global WorkPlace Solutions (GWS), manages 1.2 billion sq. ft of facility area (430 sq. miles). That’s an area virtually as giant because the land space of Los Angeles, CA (469 sq. miles).

Patrolling and usually offering a safety perimeter for GWS is a formidable enterprise. Security Sales & Integration’s Jason Knot writes about one of many latest developments in facility safety: “Dispatching AI robots from state-of the-art security alarms is going to be the future of securing buildings in a much smarter, more cost-efficient way.” Such dispatching is strictly the character of the settlement between GWS and Fremont, CA-based Cobalt Robotics, “a machine-learning company that automates repetitive manual security and facility tasks with autonomous robots.”

Patrolling and usually offering a safety perimeter for GWS is a formidable enterprise. Security Sales & Integration’s Jason Knot writes about one of many latest developments in facility safety: “Dispatching AI robots from state-of the-art security alarms is going to be the future of securing buildings in a much smarter, more cost-efficient way.” Such dispatching is strictly the character of the settlement between GWS and Fremont, CA-based Cobalt Robotics, “a machine-learning company that automates repetitive manual security and facility tasks with autonomous robots.”

Johnson Controls C•CURE 9000 entry management and occasion administration system is now built-in with Cobalt’s distant robotic guard service, which incorporates AI, robotics, machine-learning software program, and human oversight.

Mike LeBlanc, president and COO of Cobalt, mentioned of the settlement: “The integrated Johnson Controls and Cobalt solution can automate responses to major security incidents from breaches and break-ins to risks like open doors. With businesses struggling to find security guards and keep costs under control, this integrated system is the way to automate alarm response at a substantially reduced cost.”

“For many of our customers, hiring expensive security guards during a difficult labor shortage is not an option,” mentioned Johnson Controls’ Rick Focke, director of product administration. “The security workflow between our alarms and Cobalt’s robots is seamless, and all reports are automatically created and tracked so companies can make facility improvements over time.”

![]()