[ad_1]

News briefs for the week check out a brand new breed of nano warehouses and the robots that serve them, a first-ever selecting robotic that additionally consolidates orders because it goes, a brand new, three-way partnership combining experience to improve AutoStore, an automatic format printer revolutionizing the development business, and KUKA debuting a brand new AMR for intralogistics.

Robots & teeny warehouses

The unimaginable shrinking warehouse is a phenomenon of our instances. In making an attempt to get a bit brown bundle to a buyer as rapidly as doable the logistics business has needed to rethink and rework the concept of warehouses, their dimension, their location, what items they retailer, whether or not its robots and people or robots solely to choose and pack, after which what’s the following finest step to the client’s entrance door?

The business’s reply appears to be a number of small warehouses, every not more than 50 miles from buyer properties, which the business tabbed micro-fulfillment facilities (MFCs). Well, maintain that thought for a second as a result of *nano-fulfillment facilities (NFCs) have simply arrived.

The business’s reply appears to be a number of small warehouses, every not more than 50 miles from buyer properties, which the business tabbed micro-fulfillment facilities (MFCs). Well, maintain that thought for a second as a result of *nano-fulfillment facilities (NFCs) have simply arrived.

*Micro-fulfillment refers to storage areas of 900 to 4000 sqm, whereas nano-fulfillment usually begins at 75 sqm (now even smaller at 30 sqm!).

An Israeli-based startup (2021) calling itself 1MRobotics has birthed the custom-made 30-square-meter (320 sq ft) nano warehouse, presided over by a single robotic selecting and packing orders because it strikes backwards and forwards on a double-track rail system. The teeny warehouse is fitted with a street-side hatch for couriers and buyers to gather on-line orders.

1MRobotics emerged from stealth in late 2022 with $25 million for “nano-fulfillment” facilities.

1MRobotics emerged from stealth in late 2022 with $25 million for “nano-fulfillment” facilities.

Eyal Yair, co-founder and CEO of 1MRobotics, thinks his last-mile achievement answer dramatically eases the pains of CPG (client packaged items), comfort retail, and fast commerce manufacturers attending to prospects for same-day service…or sooner!

Yair is satisfied that “hyper-local logistics infrastructure” like 1MRobotics’ automated, teeny warehouses will make supermarkets redundant.

Using most any off-the-shelf robotic arms, that are then retrofitted by employees, these AI-powered robots, some lubricated to function below frigid situations, by no means see a human, besides those who come to restock the cabinets.

Picking robotic pulls double responsibility in aisles

How a couple of cell, e-commerce, piece-picking robotic that works alone but pulls off two jobs as it really works?

Jan Zizka, CEO and co-founder of Brightpick (a part of the Cincinnati-based Photoneo Brightpick Group), calls his robotic a game-changing, first-ever at working warehouse SKUs. It not solely picks gadgets but additionally consolidates all the order.

Jan Zizka, CEO and co-founder of Brightpick (a part of the Cincinnati-based Photoneo Brightpick Group), calls his robotic a game-changing, first-ever at working warehouse SKUs. It not solely picks gadgets but additionally consolidates all the order.

“Our patented Brightpick Autopicker is the most advanced fulfillment robot ever created,” he mentioned.

Impressive is the cell robotic’s capacity to take off for aisles crammed filled with SKUs, choose orders, and not should journey backwards and forwards to centralized selecting stations? The Brightpick Autopicker appears to be a loner that will get all the job accomplished!

And it’s extremely correct, so say its inventors; 99.9% correct selecting groceries, cosmetics, electronics, prescribed drugs, private care merchandise, and extra. Its proprietary machine imaginative and prescient and superior AI algorithms have been skilled on greater than 250 million picks thus far and makes use of machine studying to enhance with every choose.

Zizka and firm declare the Brightpick absolutely autonomous, end-to-end robotic answer delivers a decrease value per choose than another answer in the marketplace. Putting all of these advantages collectively finally means fewer robots to meet orders, resulting in lowered prices and improved return on funding. Major ache factors at most any warehouse or DC.

Brightpick says the system (often 10 to 100 robots) may be arrange in a month, can cut back selecting labor by 95%, and might minimize prices for order achievement in half.

The three amigos behind Apotea’s new warehouse

In what may effectively be an ongoing automation partnership between AutoStore, Element Logic, and RightHand Robotics, Sweden’s award-winning on-line pharmacy, Apotea, has simply debuted its latest warehouse, a 20,000-bin AutoStore AS/RS to choose, pack, and ship 50,000 orders per day.

It’s the primary AutoStore set up to incorporate RightPick, which is RightHand Robotics’s proprietary piece-picking know-how. Leif Jentoft, co-founder and CSO of RightHand Robotics, mentioned of the brand new partnership: “We believe this collaboration will establish a new benchmark for the intralogistics industry.”

It’s the primary AutoStore set up to incorporate RightPick, which is RightHand Robotics’s proprietary piece-picking know-how. Leif Jentoft, co-founder and CSO of RightHand Robotics, mentioned of the brand new partnership: “We believe this collaboration will establish a new benchmark for the intralogistics industry.”

RightHand’s tech is especially adept at piece-picking small pharmaceutical and healthcare gadgets. It’s been clocked at selecting over 1200 per hour. Which, after all, is right for Apotea’s pharmacy shipments.

Added to its 20,000-bin warehouse, Apotea’s AS/RS runs on 30 AutoStore R5 robots, that function 24/7. Included are three eOperator piece-picking robots, which had been developed collaboratively by RightHand Robotics and Element Logic. The eOperator, says Element Logic, makes use of machine studying to “automatically select the best way to handle an item to be picked from AutoStore”, which it claims improves order capability, items dealing with, and supply time.

Apotea’s warehouse is the primary on the earth to utilize fully-integrated eOperator robots.

Printing robotic speeds constructing course of

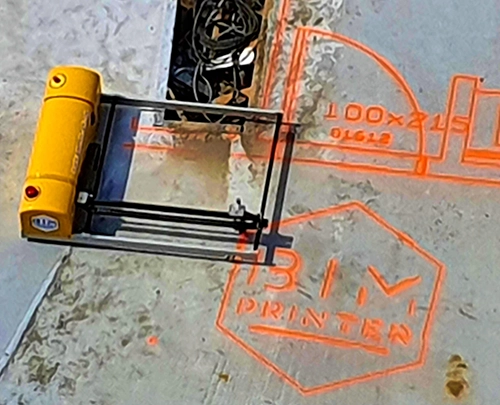

The newly-launched BIM development printer is considered one of a brand new breed of digital development robots that’s dashing up an business that’s notoriously gradual with constructing tasks.

According to MarketWatch: “The global construction industry has a chronic productivity problem. Over the past 20 years, productivity has grown at only 1% annually, only around one-third the rate of the world economy and only around one-quarter of the rate in manufacturing.”

BIMPRINTER is a completely robotic high-definition plotter, tracing at laser millimeter accuracy proper onto concrete slabs, all the related element markings vital for precise development to start.

BIMPRINTER is a completely robotic high-definition plotter, tracing at laser millimeter accuracy proper onto concrete slabs, all the related element markings vital for precise development to start.

For instance, with a 15-story constructing, every flooring must be visited by an engineer so it may be marked up for correct positioning of partitions, doorways, electrical conduits, air con, elevators, rooms, closets, and so forth. Everything must be marked up flooring by flooring; it’s laborious, error-prone, and exceedingly gradual. And clearly, the larger the constructing, the longer it takes to mark up.

Now, a robotic printer from (Andenne, Belgium-based) BIMPRINTER can do the job autonomously in a fraction of the time it will take an engineer—working from paper blueprints—to spray-paint the markings on every flooring.

BIM, by the way in which, stands for Building Information Modeling (BIM), “a technique where digital, 3D building designs and construction plans are used to guide and monitor construction processes.”

Construction employees now have a colourful information utilized on to the whole thing of every flooring that reveals precisely the work that must be accomplished.

KUKA joins the AMR battles

KUKA, one of many world’s most well-known robotic builders, threw its hat, historical past, and engineering prowess into the AMR ring with the latest debut of its KMP 600-S diffDrive.

Mightily crowded with almost 200 builders vying for gross sales consideration, AMRs (automated cell robots) are by far essentially the most explosive cell robotic class. As Interact Analysis put it: “At the end of 2020, mobile robots were deployed in just over 9,000 separate customer sites. By 2025, deployments will increase to over 53,000 sites.” The analyst goes on to say: “Over 4 million Mobile Robots Installed by Q4 2027.”

It’s an AMR that KUKA’s guardian firm, China-based Medea, the chief within the manufacturing of dwelling home equipment, may additionally use in its estimated 1500 warehouses worldwide.

With a payload capability of 600kg (1300 lbs.), the KMP 600-S was designed for high-speed help of intralogistics. The KMP 600-S safely operates utilizing laser scanners and 3D object detection, selecting out obstacles from 50mm (1.9in) to 2.1m (82.6in) above the bottom.

Additionally, KUKA’s AMR is IP54 rated providing safety towards contamination from mud and different particles, plus security from water splashes from any path.