[ad_1]

Scientists and engineers are continuously creating new supplies with distinctive properties that can be utilized for 3D printing, however determining how to print with these supplies generally is a advanced, pricey conundrum.

Often, an knowledgeable operator should use guide trial-and-error — presumably making 1000’s of prints — to find out ultimate parameters that persistently print a brand new materials successfully. These parameters embrace printing velocity and the way a lot materials the printer deposits.

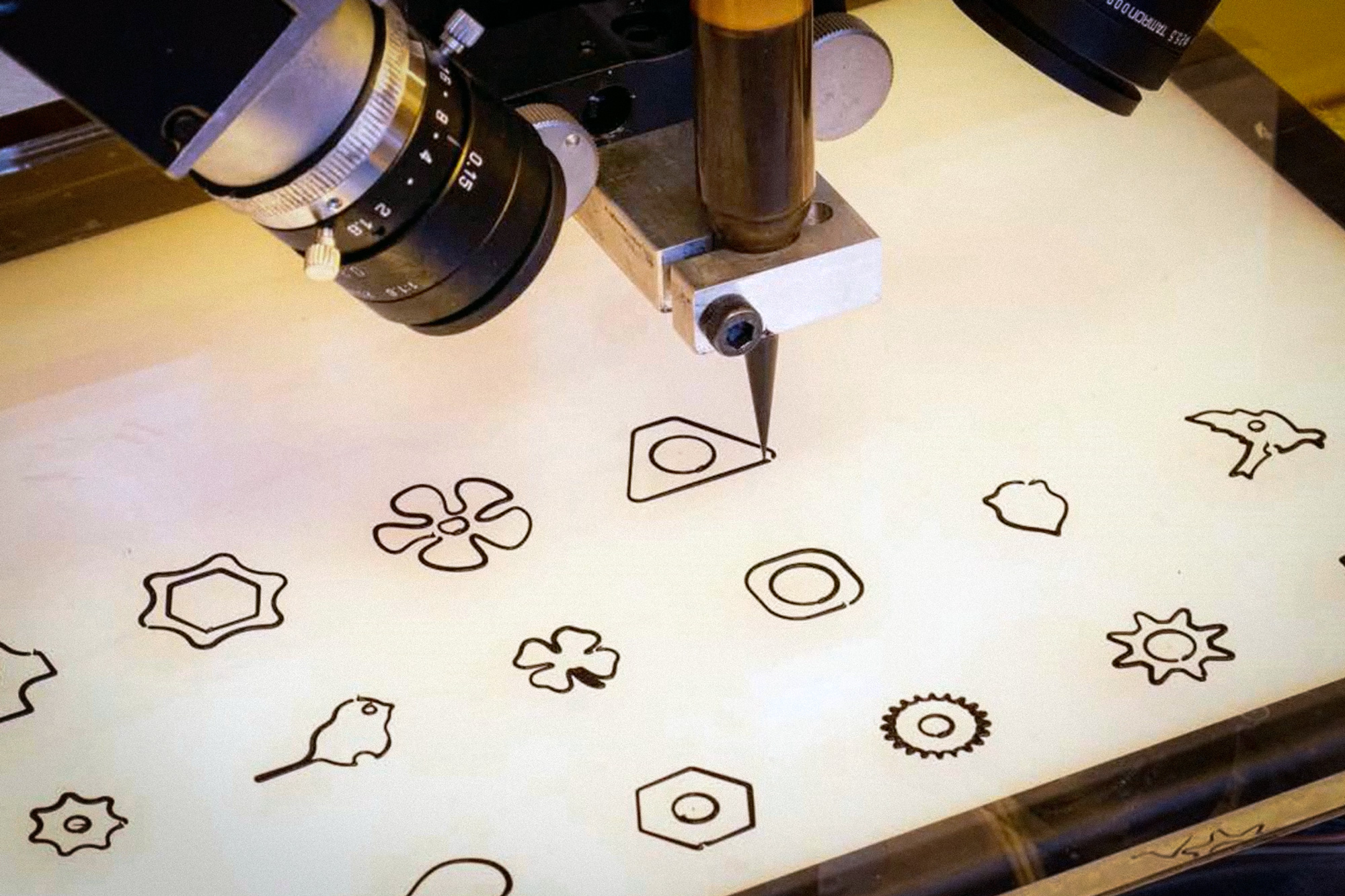

MIT researchers have now used synthetic intelligence to streamline this process. They developed a machine-learning system that makes use of pc imaginative and prescient to observe the manufacturing course of after which right errors in the way it handles the fabric in real-time.

They used simulations to show a neural community learn how to modify printing parameters to reduce error, after which utilized that controller to an actual 3D printer. Their system printed objects extra precisely than all the opposite 3D printing controllers they in contrast it to.

The work avoids the prohibitively costly means of printing 1000’s or hundreds of thousands of actual objects to coach the neural community. And it might allow engineers to extra simply incorporate novel supplies into their prints, which might assist them develop objects with particular electrical or chemical properties. It might additionally assist technicians make changes to the printing course of on-the-fly if materials or environmental circumstances change unexpectedly.

“This project is really the first demonstration of building a manufacturing system that uses machine learning to learn a complex control policy,” says senior creator Wojciech Matusik, professor {of electrical} engineering and pc science at MIT who leads the Computational Design and Fabrication Group (CDFG) inside the Computer Science and Artificial Intelligence Laboratory (CSAIL). “If you have manufacturing machines that are more intelligent, they can adapt to the changing environment in the workplace in real-time, to improve the yields or the accuracy of the system. You can squeeze more out of the machine.”

The co-lead authors on the analysis are Mike Foshey, a mechanical engineer and challenge supervisor within the CDFG, and Michal Piovarci, a postdoc on the Institute of Science and Technology in Austria. MIT co-authors embrace Jie Xu, a graduate pupil in electrical engineering and pc science, and Timothy Erps, a former technical affiliate with the CDFG.

Picking parameters

Determining the best parameters of a digital manufacturing course of could be probably the most costly elements of the method as a result of a lot trial-and-error is required. And as soon as a technician finds a mix that works effectively, these parameters are solely ultimate for one particular state of affairs. She has little knowledge on how the fabric will behave in different environments, on totally different {hardware}, or if a brand new batch displays totally different properties.

Using a machine-learning system is fraught with challenges, too. First, the researchers wanted to measure what was occurring on the printer in real-time.

To do that, they developed a machine-vision system utilizing two cameras aimed on the nozzle of the 3D printer. The system shines mild at materials as it’s deposited and, primarily based on how a lot mild passes by means of, calculates the fabric’s thickness.

“You can think of the vision system as a set of eyes watching the process in real-time,” Foshey says.

The controller would then course of photos it receives from the imaginative and prescient system and, primarily based on any error it sees, modify the feed price and the course of the printer.

But coaching a neural network-based controller to grasp this manufacturing course of is data-intensive, and would require making hundreds of thousands of prints. So, the researchers constructed a simulator as an alternative.

Successful simulation

To practice their controller, they used a course of referred to as reinforcement studying during which the mannequin learns by means of trial-and-error with a reward. The mannequin was tasked with deciding on printing parameters that may create a sure object in a simulated setting. After being proven the anticipated output, the mannequin was rewarded when the parameters it selected minimized the error between its print and the anticipated end result.

In this case, an “error” means the mannequin both allotted an excessive amount of materials, putting it in areas that ought to have been left open, or didn’t dispense sufficient, leaving open spots that ought to be crammed in. As the mannequin carried out extra simulated prints, it up to date its management coverage to maximise the reward, changing into increasingly more correct.

However, the actual world is messier than a simulation. In apply, circumstances sometimes change because of slight variations or noise within the printing course of. So the researchers created a numerical mannequin that approximates noise from the 3D printer. They used this mannequin so as to add noise to the simulation, which led to extra real looking outcomes.

“The interesting thing we found was that, by implementing this noise model, we were able to transfer the control policy that was purely trained in simulation onto hardware without training with any physical experimentation,” Foshey says. “We didn’t need to do any fine-tuning on the actual equipment afterwards.”

When they examined the controller, it printed objects extra precisely than another management technique they evaluated. It carried out particularly effectively at infill printing, which is printing the inside of an object. Some different controllers deposited a lot materials that the printed object bulged up, however the researchers’ controller adjusted the printing path so the thing stayed stage.

Their management coverage may even learn the way supplies unfold after being deposited and modify parameters accordingly.

“We were also able to design control policies that could control for different types of materials on-the-fly. So if you had a manufacturing process out in the field and you wanted to change the material, you wouldn’t have to revalidate the manufacturing process. You could just load the new material and the controller would automatically adjust,” Foshey says.

Now that they’ve proven the effectiveness of this system for 3D printing, the researchers need to develop controllers for different manufacturing processes. They’d additionally prefer to see how the method could be modified for situations the place there are a number of layers of fabric, or a number of supplies being printed directly. In addition, their method assumed every materials has a hard and fast viscosity (“syrupiness”), however a future iteration might use AI to acknowledge and modify for viscosity in real-time.

Additional co-authors on this work embrace Vahid Babaei, who leads the Artificial Intelligence Aided Design and Manufacturing Group on the Max Planck Institute; Piotr Didyk, affiliate professor on the University of Lugano in Switzerland; Szymon Rusinkiewicz, the David M. Siegel ’83 Professor of pc science at Princeton University; and Bernd Bickel, professor on the Institute of Science and Technology in Austria.

The work was supported, partially, by the FWF Lise-Meitner program, a European Research Council beginning grant, and the U.S. National Science Foundation.

[ad_2]