[ad_1]

As EV manufacturing and, with it, battery manufacturing speed up over the following decade, so too will the demand for rigorous EV battery testing. But producing a battery that can stand as much as the duty of powering an electrical car for years below completely different climate situations and unpredictable utilization patterns is not any imply feat. Battery producers must prove many extra items appropriate for EV calls for whereas nonetheless performing the array of checks they need to perform to guarantee automakers and customers that the batteries they’re turning out meet primary requirements for efficiency, security, and sturdiness.

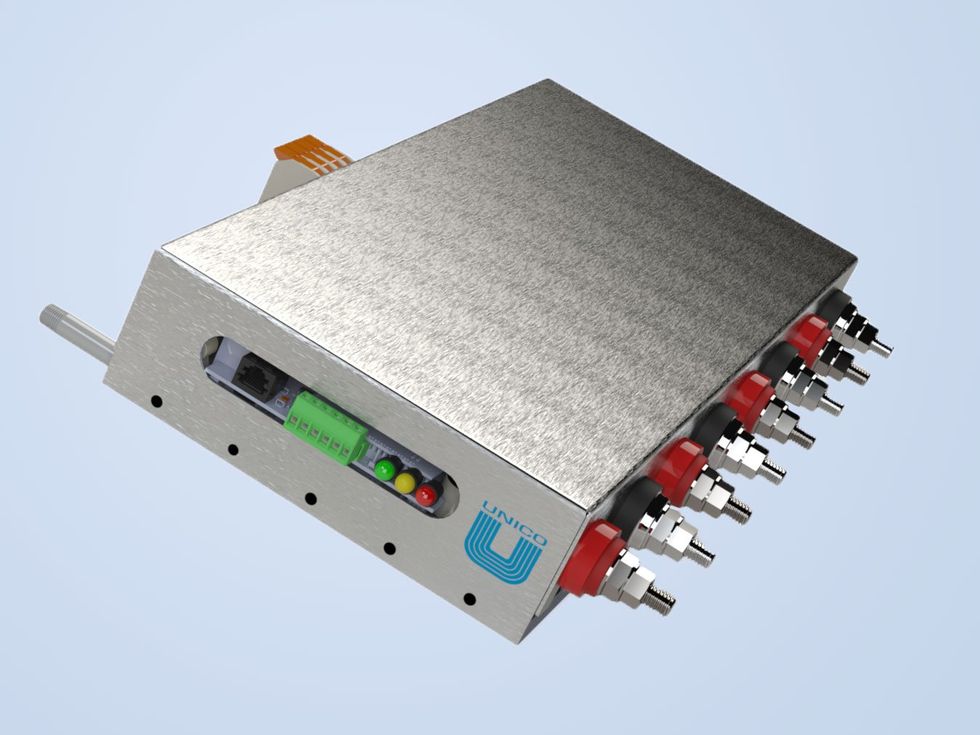

At the International Battery Seminar & Exhibit held 12-15 March in Orlando, lots of the world’s main battery makers, take a look at tools producers, and theorists gathered to speak about advances within the subject and to current new merchandise claiming to make the battery manufacturing course of faster and cheaper. One such product household was the BAT300 collection electrical energy testing units made by Unico.

Unico says the compact items are nicely fitted to use at three crucial battery-production phases: cell formation; fault testing as cells are gathered into packs and packs are gathered into full batteries; and for end-of-the-line cost biking to assist predict what number of charge-discharge cycles a battery will undergo earlier than it’s now not able to holding sufficient cost for car propulsion. Unico vice chairman of engineering Don Wright instructed IEEE Spectrum that the BAT300 collection can be good for conducting capability checks when an organization needs to test cells it bought from one other producer.

“Battery companies have expended enormous effort on predictive modeling.” —Paul Kohl, Georgia Institute of Technology

At the battery seminar, Wright confirmed off a BAT300 take a look at channel designed to transform a 400 or 800 volt direct present right down to a ten volt present for cell formation or cell testing. The potential advantages of Unico’s product are important sufficient that it was named a finalist for the battery seminar’s “Best in Show” award.

But necessary questions stay. “It may be a wonderful product. But it’s such a complicated set of things [Unico] is claiming,” says Paul Kohl, a professor on the Georgia Institute of Technology’s School of Chemical and Biomolecular Engineering in Atlanta.

“Does it really do all those things?” says Kohl, whose main analysis pursuits embody superior interconnects for built-in circuits and electrochemical units for power conversion and storage together with lithium-ion batteries and alkaline gas cells. “If it did any one of those things really well,” says Kohl, “that would be amazing.”

“Battery companies have expended enormous effort on predictive modeling, trying to be able to forecast when a battery will reach the end of its service life without having to cycle test it to that point,” says Kohl. “They’re all very private about exactly what they do, but everyone does pretty much the same thing. They cycle batteries and look for signatures in the current and voltage which follow a trend. And they’ll take a few batteries all the way to the end of life, then use that empirical data for extrapolating to the end of life for the thousands of other batteries that they put through only a few cycles.”

Big producers have already got battery testing instruments

The open query is whether or not Unico’s product does it higher than the instruments main battery producers corresponding to LG or Samsung already use. There are hundreds of publications about this, together with lots sponsored by the U.S. Department of Energy. “Does Unico have something that is somehow better than what everyone else has been doing?” Kohl says. “Only the market will tell.”

Kohl says the BAT300 collection is likely to be great for battery producers which aren’t on the size of LG or Samsung: ”Companies which can be, by far, the world’s consultants in how batteries age,” he says. Smaller firms that don’t have the in-house experience the giants have acquired would all of the sudden have a sophisticated instrument that may elevate the standard of their batteries.

“It would take a lot of faith for you to do a simple electrical test and guarantee that nothing bad will happen if you smash this battery with a hammer.” —Paul Kohl, Georgia Institute of Technology

Though electrical car batteries not often catch fireplace—at the least in contrast with the propensity of fires in automobiles with inside combustion engines—the conflagrations attributable to low-cost, knockoff batteries on the low finish of the EV market have engendered a considerably unwarranted wariness concerning the relative security of EVs. Kohl and Wright agree of their hope that tools like Unico’s will assist carry an finish to firms shopping for or promoting batteries that haven’t undergone testing protocols that make EV battery fires much more of a rarity.

Still, Kohl factors out, “In this unit they presented, they can only do so much. It can do an electrical test, looking for certain signatures that indicate issues that could cause electrical faults or premature loss of capacity at some later time, but [it doesn’t carry out] the array of Underwriters Laboratory–style physical tests where they pound batteries, heat them up, and drive nails through them to see what it takes to get them to catch fire or otherwise fail. It would take a lot of faith for you to do a simple electrical test and guarantee that nothing bad will happen if you smash this battery with a hammer, or if it gets into a car accident, or the temperature goes up to 150 degrees Fahrenheit.”

Better battery testing tech may jumpstart the used EV market

To be truthful, Unico says that the BAT300 collection is meant for functions the place costly, research-level instruments ship greater than what’s wanted, however low-cost, entry-level instruments don’t do fairly sufficient. One doable utility is the used car market. Once vehicles have been pushed off of automobile heaps, checks that decision for bodily abuse are out of the query. That is the purpose at which detailed however simple and cheap electrical evaluation can be indispensable.

According to a research accomplished by the United Kingdom’s Society of Motor Manufacturers and Traders (SMMT), the nation’s used EV market, although tiny right this moment at 1.6 p.c of gross sales, will finally be as massive as right this moment’s used automobile marketplace for automobiles with inside combustion engines, which accounts for 82 p.c of gross sales. “ Different makes and models test in different ways, so an individual manufacturer would struggle to test any other vehicles which their dealerships might sell after a trade-in,” says Alexander Johns, partnership lead at Altelium, a consultancy headquartered in London that gives warranties and insurance coverage to firms that cope with batteries at any stage of their life cycle.

Altelium additionally conducts battery well being checks and points battery well being certificates that current an sincere dealer’s notion of what an electrical car ought to promote for on the secondary market. Because of the broad variance in how batteries are arrange in electrical automobiles, says Johns, “the [secondary] market is adopting third-party solutions which could offer nearly universally applicable test services.”

That’s a candy spot which looks like a pure match for instruments like those Unico produces. Perhaps insurers like Altelium will use instruments like Unico’s to certify the capability of EV batteries and inform a would-be purchaser the estimated variety of remaining cost cycles earlier than a automobile’s battery will have to be changed. That all-important information can be crucial to setting a purchaser’s expectations and go a good distance towards leaving a great impression.

From Your Site Articles

Related Articles Around the Web