[ad_1]

Earlier this week, the Toyota Research Institute opened the doorways of its Bay Area workplaces to members of the media for the primary time. It was a day filled with demos, starting from driving simulators and drifting instructors to conversations round machine studying and sustainability.

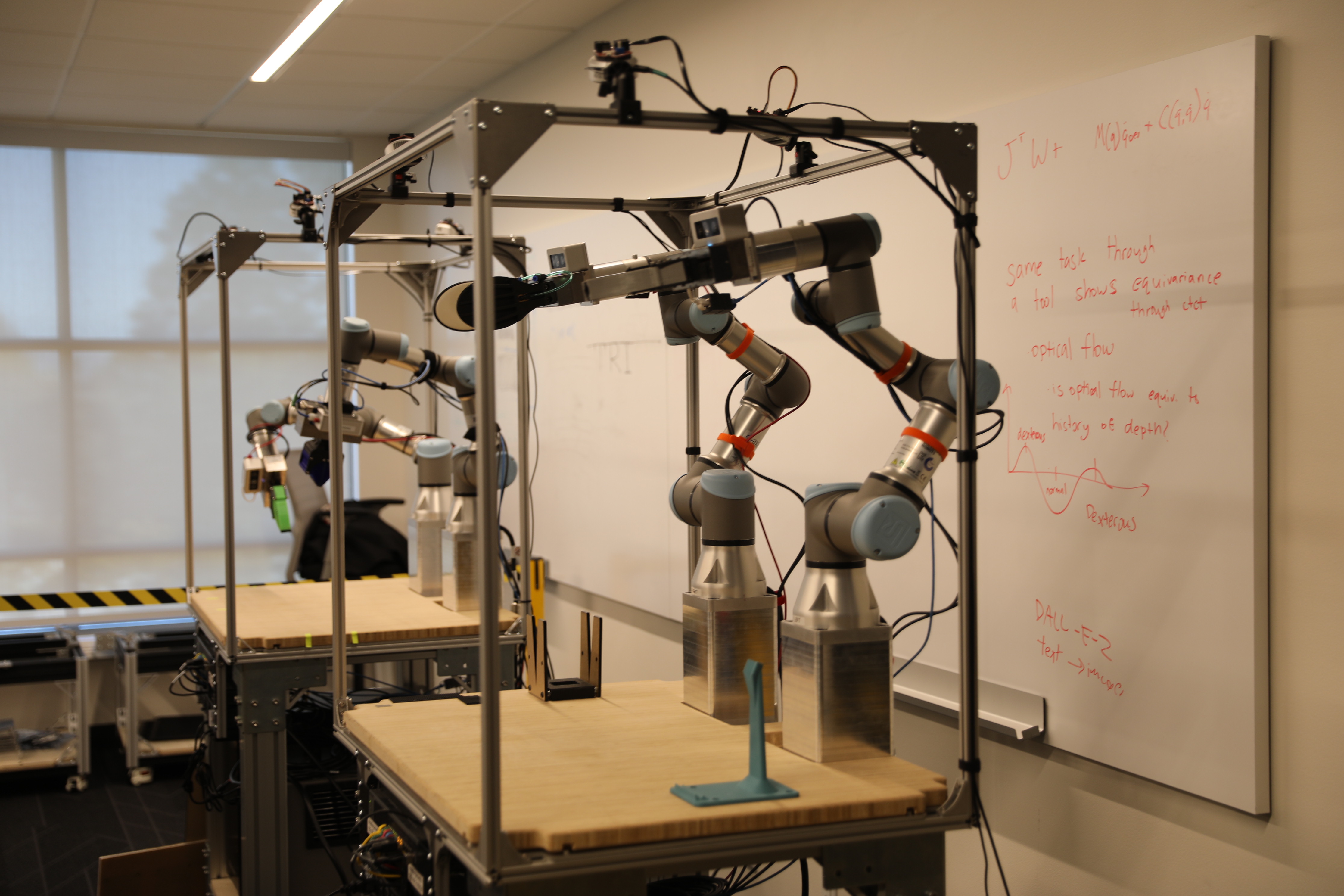

Robotics, a longtime focus of Toyota’s analysis division, had been on show, as properly. SVP Max Bajracharya showcased a pair of tasks. First was one thing extra alongside the strains of what one would count on from Toyota: an industrial arm with a modified gripper designed for the surprisingly complicated job of transferring bins from the again of a truck to close by conveyor belts — one thing most factories are hoping to automate sooner or later.

The different is a little more stunning — no less than for many who haven’t adopted the division’s work that intently. A procuring robotic retrieves totally different merchandise on the shelf primarily based on bar codes and basic location. The system is ready to lengthen to the highest shelf to search out gadgets, earlier than figuring out the perfect technique for greedy the broad vary of various objects and dropping them into its basket.

The system is a direct outgrowth of the 50-person robotics staff’s concentrate on eldercare, geared toward addressing Japan’s getting older inhabitants. It does, nevertheless, symbolize a pivot away from their authentic work of constructing robots designed to execute family duties like dishwashing and meals prep.

You can learn a lengthier writeup of that pivot in an article published on TechCrunch earlier this week. That was drawn from a dialog with Bajracharya, which we’re printing in a extra full state beneath. Note that the textual content has been edited for readability and size.

Image Credits: Brian Heater

TechCrunch: I hoped to get a demo of the house robotic.

Max Bajracharya: We are nonetheless performing some house robotic stuff[…] What we’ve executed has shifted. Home was considered one of our authentic problem duties.

Eldercare was the primary pillar.

Absolutely. One of the issues that we realized in that course of is that we weren’t capable of measure our progress very properly. The house is so onerous. We choose problem duties as a result of they’re onerous. The downside with the house isn’t that it was too onerous. It was that it was too onerous to measure the progress we had been making. We tried numerous issues. We tried procedurally making a large number. We would put flour and rice on the tables and we might attempt to wipe them up. We would put issues all through the home to make the robotic tidy. We had been deploying into Airbnbs to see how properly we had been doing, however the issue is we couldn’t get the identical house each time. But if we did, we might overfit to that house.

Isn’t that perfect that you just don’t get the identical house each time?

Exactly, however the issue is we couldn’t measure how properly we had been doing. Let’s say we had been a bit of higher at tidying this one home, we don’t know if that’s as a result of our capabilities acquired higher or if that home was a bit of simpler. We had been doing the usual, “show a demo, show a cool video. We’re not good enough yet, here’s a cool video.” We didn’t know whether or not we had been making good progress or not. The grocery problem job the place we mentioned, we want an surroundings the place it’s as onerous as a house or has the identical consultant issues as a house, however the place we are able to measure how a lot progress we’re making.

You’re not speaking about particular objectives to both the house or grocery store, however fixing for issues that may span each of these locations.

Or even simply measure if we’re pushing the cutting-edge in robotics. Are we capable of do the notion, the movement planning, the behaviors which are, the truth is, basic objective. To be completely trustworthy, the problem downside sort of doesn’t matter. The DARPA Robotics Challenges, these had been simply made-up duties that had been onerous. That’s true of our problem duties, too. We like the house as a result of it’s consultant of the place we ultimately need to be serving to individuals within the house. But it doesn’t need to be the house. The grocery market is an excellent illustration as a result of it has that massive variety.

Image Credits: Brian Heater

There’s a frustration, although. We understand how troublesome these challenges are and the way far off issues are, however some random individual sees your video, and all of the sudden it’s one thing that’s simply over the horizon, although you may’t ship that.

Absolutely. That’s why Gill [Pratt] says each time, ‘reemphasize why this is a challenge task.’

How do you translate that to regular individuals? Normal individuals aren’t hung up on problem duties.

Exactly, however that’s why within the demonstration you noticed at present, we tried to point out the problem duties, but in addition one instance of how you’re taking capabilities that come out of that problem and apply it to an actual software like unloading a container. That is an actual downside. We went to factories they usually mentioned, ‘yes, this is a problem. Can you help us?’ And we mentioned, yeah, we have now applied sciences that apply to that. So now we’re attempting to point out popping out of those challenges are these couple of few breakthroughs that we predict are essential, after which apply these to actual functions. And I believe that that’s been serving to individuals perceive that, as a result of they see that second step.

How giant is the robotics staff?

The division is about 50 individuals evenly cut up between right here and Cambridge, Massachusetts.

You have examples like Tesla and Figure, which try to make all-purpose humanoid robots. You appear to be heading in a distinct route.

A little bit bit. Something we’ve noticed is that the world is constructed for people. If you’ve simply acquired a clean slate, you’re saying I need to construct a robotic to work in human areas. You have a tendency to finish in human proportions and human-level capabilities. You finish with human legs and arms, not as a result of that’s the optimum answer, essentially. It’s as a result of the world has been designed round individuals.

Image Credits: Toyota Research Institute

How do you measure milestones? What does success seem like on your staff?

Moving from the house to the grocery retailer is a superb instance of that. We had been making progress on the house however not as quick and never as clearly as after we transfer to the grocery retailer. When we transfer to the grocery retailer, it actually turns into very evident how properly you’re doing and what the actual issues are in your system. And then you may actually concentrate on fixing these issues. When we toured each logistics and manufacturing services of Toyota, we noticed all of those alternatives the place they’re mainly the grocery procuring problem, besides a bit of bit totally different. Now, the half as an alternative of the elements being grocery gadgets, the elements are all of the elements in a distribution middle.

You hear from 1,000 those who you realize, house robots are actually onerous, however you then really feel like you need to strive for your self and you then like, actually, you make all the identical errors that they did.

I believe I’m in all probability simply as responsible as everyone else. It’s like, now our GPUs are higher. Oh, we acquired machine studying and now you realize we are able to do that. Oh, okay, possibly that was tougher than we thought.

Something has to tip it sooner or later.

Maybe. I believe it’s going to take a very long time. Just like automated driving, I don’t suppose there’s a silver bullet. There’s not identical to this magical factor, that’s going to be ‘okay, now we solved it.’ It’s going to be chipping away, chipping away, incrementally. That’s why it’s essential to have that sort of roadmap with the shorter timelines, you realize, shorter or shorter milestones that provide the little wins, so you may maintain working at it to actually obtain that long-term imaginative and prescient.

What’s the method for really productizing any of those applied sciences?

That’s an excellent query that we’re ourselves attempting to reply. I consider we sort of perceive the panorama now. Maybe I used to be naïve at first considering that, okay, we simply want to search out this this person who we’re going to throw the expertise over to a 3rd occasion or any individual inside Toyota. But I believe we’ve realized that, no matter it’s — whether or not it’s a enterprise unit, or an organization, or like a startup or a unit inside Toyota — they don’t appear to exist. So, we’re looking for a approach of making and I believe that’s the story of TRI-AD, a bit of bit as properly. It was created to take the automated driving analysis that we had been doing and translate into one thing that was extra actual. We have the identical downside in robotics, and in most of the superior applied sciences that we that we work on.

Image Credits: Brian Heater

You’re excited about doubtlessly attending to a spot the place you may have spinoffs.

Potentially. But it’s not the principle mechanism by which we might commercialize the expertise.

What is the principle mechanism?

We don’t know. The reply is the variety of issues that we’re doing could be very seemingly going to be totally different for various teams.

How has TRI modified since its basis?

When I first began, I really feel like we had been very clearly simply doing analysis in robotics. Part of that’s as a result of we had been simply so very distant from the expertise being relevant to virtually any real-world difficult software in a human surroundings. Over the final 5 years, I really feel like we’ve made sufficient progress in that very difficult downside that we at the moment are beginning to see it flip into these real-world functions. We have consciously shifted. We’re nonetheless 80% pushing the cutting-edge with analysis, however we’ve now allotted possibly 20% of our assets to determining if that analysis is possibly pretty much as good as we predict it’s and if it may be utilized to real-world functions. We may fail. We may notice we thought we made some attention-grabbing breakthroughs, however it’s not anyplace close to dependable or quick sufficient. But we’re placing 20% of our effort towards attempting.

How does eldercare match into this?

I’d say, in some methods, it’s nonetheless our north star. The tasks are nonetheless how we finally amplify individuals of their houses. But over time, as we choose these problem duties, if issues trickle out which are relevant to those different areas, that’s the place we’re utilizing these short-term milestones to point out the progress within the analysis that we’re making.

How reasonable is the opportunity of a completely lights-out issue?

I believe for those who had been capable of begin from scratch in possibly sooner or later, that is likely to be a chance. If I take a look at manufacturing at present, particularly for Toyota, it appears most unlikely that you may get anyplace near that. We [told factory workers], we’re constructing robotic expertise, the place do you suppose it might apply? They confirmed us many, many processes the place it was issues like, you’re taking this wire harness, you feed it by right here, you then pull it out right here, you then clip it right here, and also you clip it right here, and you’re taking it right here, and you’re taking it right here, and you then run it like this. And this takes an individual 5 days to study the ability. We had been like, ‘yeah, that’s approach too onerous for the robotic expertise.’

But the issues which are probably the most troublesome for individuals are those you’d need to automate.

Yes, troublesome or doubtlessly harm susceptible. For certain, we want to make stepping stones to get to that ultimately, however the place I see robotic expertise at present, we’re fairly distant from that.