[ad_1]

Top 5 Robot Trends 2023 © International Federation of Robotics

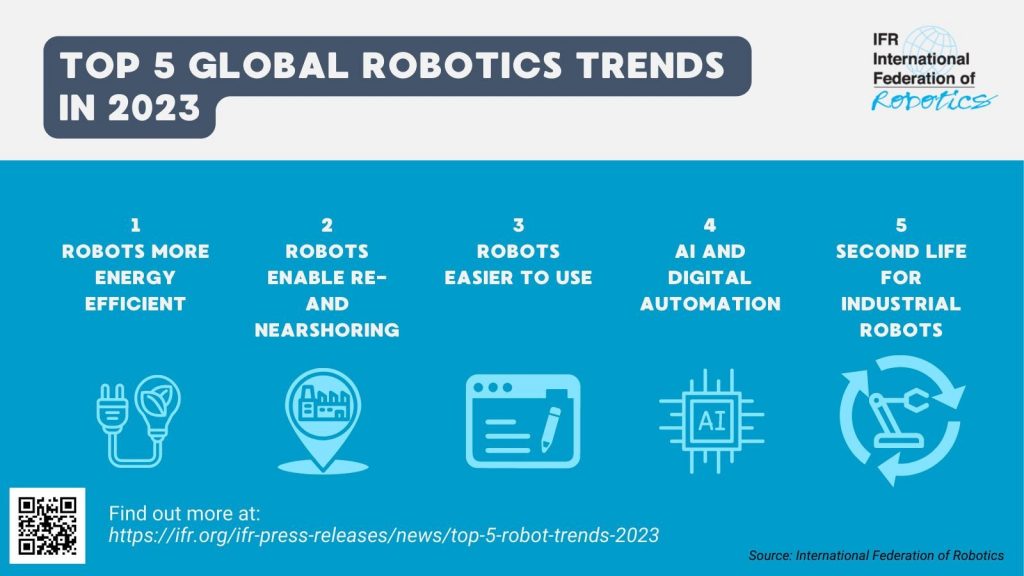

The inventory of operational robots across the globe hit a brand new report of about 3.5 million items – the worth of installations reached an estimated 15.7 billion USD. The International Federation of Robotics analyzes the highest 5 traits shaping robotics and automation in 2023.

“Robots play a fundamental role in securing the changing demands of manufacturers around the world,” says Marina Bill, President of the International Federation of Robotics. “New trends in robotics attract users from small enterprise to global OEMs.”

1 – Energy Efficiency

Energy effectivity is essential to enhance corporations’ competitiveness amid rising power prices. The adoption of robotics helps in some ways to decrease power consumption in manufacturing. Compared to conventional meeting traces, appreciable power financial savings will be achieved by means of lowered heating. At the identical time, robots work at excessive pace thus growing manufacturing charges in order that manufacturing turns into extra time- and energy-efficient.

Today’s robots are designed to devour much less power, which results in decrease working prices. To meet sustainability targets for his or her manufacturing, corporations use industrial robots geared up with power saving expertise: robotic controls are in a position to convert kinetic power into electrical energy, for instance, and feed it again into the facility grid. This expertise considerably reduces the power required to run a robotic. Another function is the good energy saving mode that controls the robotic´s power provide on-demand all through the workday. Since industrial services want to watch their power consumption even right this moment, such related energy sensors are more likely to develop into an trade commonplace for robotic options.

2 – Reshoring

Resilience has develop into an necessary driver for reshoring in numerous industries: Car producers e.g. make investments closely briefly provide traces to convey processes nearer to their clients. These producers use robotic automation to fabricate highly effective batteries cost-effectively and in massive portions to help their electrical car initiatives. These investments make the cargo of heavy batteries redundant. This is necessary as an increasing number of logistics corporations refuse to ship batteries for security causes.

Relocating microchip manufacturing again to the US and Europe is one other reshoring pattern. Since most industrial merchandise these days require a semiconductor chip to perform, their provide near the shopper is essential. Robots play an important position in chip manufacturing, as they dwell as much as the acute necessities of precision. Specifically designed robots automate the silicon wafer fabrication, take over cleansing and cleaning duties or check built-in circuits. Recent examples of reshoring are Intel´s new chip factories in Ohio or the not too long ago introduced chip plant within the Saarland area of Germany run by chipmaker Wolfspeed and automotive provider ZF.

3 – Robots simpler to make use of

Robot programming has develop into simpler and extra accessible to non-experts. Providers of software-driven automation platforms help corporations, letting customers handle industrial robots with no prior programming expertise. Original tools producers work hand-in-hand with low code and even no-code expertise companions that permit customers of all ability ranges to program a robotic.

The easy-to-use software program paired with an intuitive consumer expertise replaces in depth robotics programming and opens up new robotics automation alternatives: Software start-ups are getting into this market with specialised options for the wants of small and medium-sized corporations. For instance: a standard heavy-weight industrial robotic will be geared up with sensors and a brand new software program that enables collaborative setup operation. This makes it simple for staff to regulate heavy equipment to completely different duties. Companies will thus get the very best of each worlds: strong and exact industrial robotic {hardware} and state-of-the-art cobot software program.

Easy-to-use programming interfaces, that permit clients to arrange the robots themselves, additionally drive the rising new section of low-cost robotics. Many new clients reacted to the pandemic in 2020 by attempting out robotic options. Robot suppliers acknowledged this demand: Easy setup and set up, for example, with pre-configured software program to deal with grippers, sensors or controllers help lower-cost robotic deployment. Such robots are sometimes offered by means of net outlets and program routines for numerous purposes are downloadable from an app retailer.

4 – Artificial Intelligence (AI) and digital automation

Propelled by advances in digital applied sciences, robotic suppliers and system integrators supply new purposes and enhance current ones relating to pace and high quality. Connected robots are reworking manufacturing. Robots will more and more function as a part of a related digital ecosystem: Cloud Computing, Big Data Analytics or 5G cell networks present the technological base for optimized efficiency. The 5G commonplace will allow absolutely digitalized manufacturing, making cables on the shopfloor out of date.

Artificial Intelligence (AI) holds nice potential for robotics, enabling a spread of advantages in manufacturing. The principal intention of utilizing AI in robotics is to raised handle variability and unpredictability within the exterior setting, both in real-time, or off-line. This makes AI supporting machine studying play an growing position in software program choices the place operating methods profit, for instance with optimized processes, predictive upkeep or vision-based gripping.

This expertise helps producers, logistics suppliers and retailers coping with steadily altering merchandise, orders and inventory. The higher the variability and unpredictability of the setting, the extra doubtless it’s that AI algorithms will present a cheap and quick answer – for instance, for producers or wholesalers coping with tens of millions of various merchandise that change frequently. AI can also be helpful in environments wherein cell robots want to differentiate between the objects or individuals they encounter and reply otherwise.

5 – Second life for industrial robots

Since an industrial robotic has a service lifetime of as much as thirty years, new tech tools is a superb alternative to provide outdated robots a “second life”. Industrial robotic producers like ABB, Fanuc, KUKA or Yaskawa run specialised restore facilities near their clients to refurbish or improve used items in a resource-efficient manner. This prepare-to-repair technique for robotic producers and their clients additionally saves prices and sources. To supply long-term restore to clients is a vital contribution to the round economic system.

International Federation of Robotics (IFR)

connects the world of robotics across the globe. We intention at selling the optimistic advantages of robots for productiveness, competitiveness, financial progress and high quality of labor and life.

International Federation of Robotics (IFR)

connects the world of robotics across the globe. We intention at selling the optimistic advantages of robots for productiveness, competitiveness, financial progress and high quality of labor and life.