[ad_1]

It’s January 2030 and your electrical warmth pump is warming the home whereas your electrical automotive costs within the storage, all powered by photo voltaic panels in your roof and by wind and photo voltaic mills at your native utility. It doesn’t matter that it’s been raining for 2 weeks as a result of your utility is tapping into ammonia produced with final summer season’s sunshine. It’s consuming that ammonia in a linear generator.

The linear generator can shortly

change between various kinds of inexperienced (and not-so-green, if want be) gas, together with biogas, ammonia, and hydrogen. It has the potential to make the decarbonized energy system obtainable, dependable, and resilient towards the vagaries of climate and of gas provides. And it’s not a fantasy; it’s been developed, examined, and deployed commercially.

The cofounders of

Mainspring Energy, of which I’m one, spent 14 years growing this expertise, and in 2020 we started rolling it out commercially. It is at the moment put in at tens of websites, producing 230 to 460 kilowatts at every. We count on linear mills at many extra areas to return on line inside the subsequent yr.

It began at Stanford

The story of the linear generator started practically twenty years in the past at

Stanford University’s Advanced Energy Systems Laboratory, when mechanical engineering professor Christopher Edwards requested a few of us Ph.D. college students a easy query: “What is the most efficient and practical way possible to convert chemical-bond energy into useful work?”

We began by contemplating gas cells, since they are often very environment friendly. But gas cells use catalysts to set off the chemical reactions that launch vitality, and catalysts usually value lots, degrade over time, and reply poorly to fast adjustments in load. So we started searching for an alternate.

We knew that we may set off the discharge of vitality just by compressing a mix of air and gas. Here’s how that may work.

The environment friendly, clear,

The environment friendly, clear,

flameless response

on the coronary heart of the

Mainspring generator

works with practically

any gas, together with

carbon-free ammonia

as proven right here. The

ammonia reacts with

oxygen in air to

produce nitrogen fuel

and water, and the

ensuing drive pushes

towards the partitions of

the field.

Mainspring

First, gas and air enter a closed chamber with movable finish partitions. Next, these finish partitions transfer towards one another, compressing the combination of gas and air. As this occurs, the molecules inside the combination collide sooner and sooner, till they eventually break aside and re-form into totally different molecules, releasing the vitality saved of their chemical bonds. That vitality causes the brand new molecules to collide even sooner and extra typically, not simply with themselves but additionally with the partitions of the chamber, elevating the stress within the chamber. It all occurs and not using a spark or another ignition supply.

The stress pushes the partitions outward with extra drive than that wanted to push them inward at the start of the cycle. Once these partitions attain their preliminary place, and the stress inside the chamber reverts to its preliminary state, a brand new batch of gas and air flows in, pushing the molecules created by the earlier cycle out of the chamber and beginning the method throughout. That’s the speculation. To try it out, in 2008 we constructed an equipment able to compressing via a quantity 100 occasions that of the beginning worth, then increasing again once more. We used a metallic tube two meters lengthy and 50 millimeters in diameter, with a closed wall on one finish and a metallic slug because the transferring wall. This association works like a piston that compresses a fuel inside a cylinder in an engine, though that’s the place the similarities finish—the “piston” in our machine was not connected to a crankshaft, or to something in any respect. I’ll talk about in a second the restrictions of such a engine structure for this sort of response, and the way we solved them with a brand new kind of machine. But it was place to start out.

Our first machine was quite simple—it may run just one “shot” at a time, and it didn’t produce electrical energy; that’s, we didn’t harvest the vitality produced. But we may use it to measure the effectivity of the response, which means the additional push that have to be utilized to the transferring wall throughout growth relative to how a lot gas was used. And the outcomes have been wonderful,

the machine was environment friendly as a gas cell, simply as we had hoped. Now we needed to construct a model that might generate electrical energy and run for years at an affordable value. In 2010, Shannon Miller, Adam Simpson, and I included Mainspring Energy to construct a real-world system. Khosla Ventures supplied our preliminary seed cash; so far we’ve raised greater than US $500 million from a variety of buyers, together with Khosla, American Electric Power, Bill Gates, and NextPeriod Energy.

Generators that use the flameless compression response had been constructed earlier than in analysis labs, primarily based on a traditional combustion-engine structure, however they have been restricted by the problem of controlling the response in such a equipment. To be environment friendly, the combination must be compressed simply sufficient to provoke the response. If compression continues after the response occurs, it fights towards the stress generated by the response, losing vitality. If compression stops too quickly, the response by no means occurs.

This optimum compression varies with situations, starting with the selection of gas: Hydrogen, for instance, reacts with much less compression than ammonia. Running at a partial energy output as an alternative of full energy or working on a scorching day versus a chilly one, additionally adjustments the optimum compression.

A traditional engine harvests vitality when the additional stress generated from the response pushes on a piston, which pushes on a connecting rod to rotate a crankshaft. The crankshaft geometry constrains the piston to all the time comply with the identical movement, and due to this fact the identical quantity of compression, it doesn’t matter what. Such an engine can’t adapt to adjustments within the required compression, and that makes it onerous to manage the response.

So quite than mimicking an engine, we designed a brand new machine that ties the compression and growth movement on to the technology of electrical energy, and in doing so gives the mandatory response management. This machine ended up trying fully totally different from—and having nearly no elements in widespread with—a traditional engine. So we felt a brand new title was wanted, and we referred to as it the linear generator.

How the linear generator works

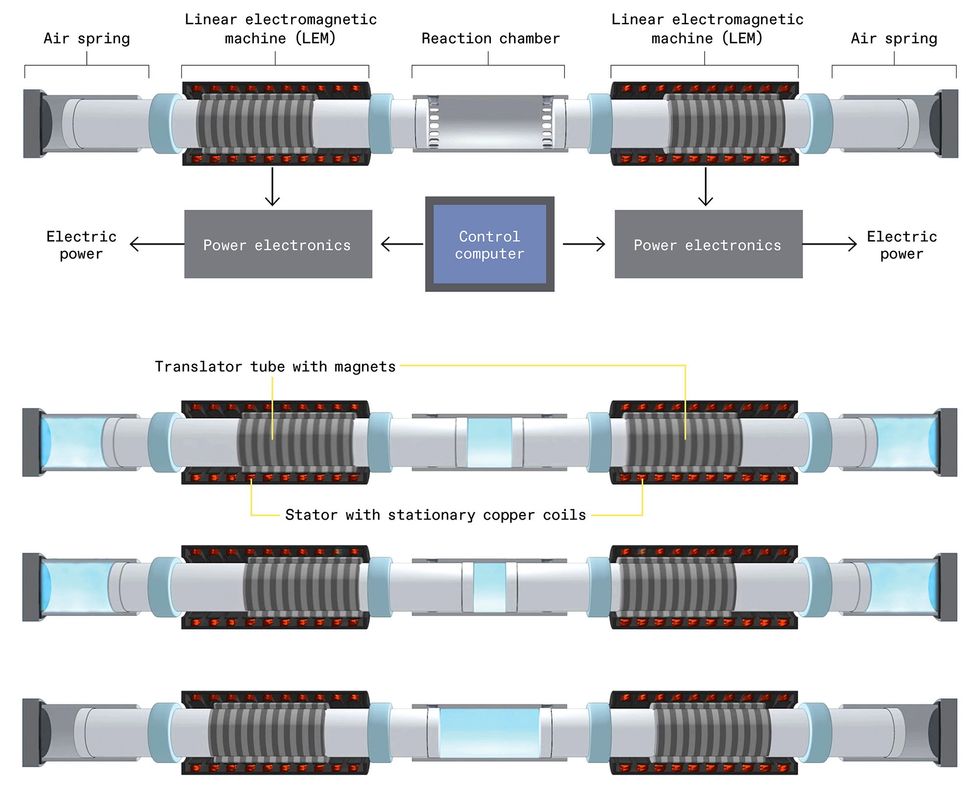

Picture a sequence of 5 cylindrical assemblies organized in a line, held inside a boxlike body. The central tube is the response chamber; it’s the place the gas and air go. On both facet of it sits a linear electromagnetic machine (LEM) that converts the push from stress straight into electrical energy. At every finish of the generator is an air-filled cylindrical chamber that acts as a spring to bounce the transferring a part of the LEM again to the middle. The complete association—two air springs, two LEMS, and a response chamber—types a linear generator core. It’s lengthy and thin: A machine rated at 115 kW is about 5.5 meters lengthy and about 1 meter excessive and extensive.

The LEM, in precept, is an electrical motor that has been unrolled to kind a line as an alternative of a circle. It consists of a transferring half—the translator—and a stationary half—the stator. The translator is an extended, straight tube with an array of neodymium everlasting magnets connected to the perimeter, close to the middle. An finish plate caps every translator tube and seals to the internal floor of the response chamber. The capped finish of the translator does the precise compression, because the piston would in an engine, however it’s wildly totally different in design. The stator is a sequence of copper coils. As the translator strikes forwards and backwards in a straight line contained in the coils, the magnets generate present that feeds an 800-volt DC bus.

In Mainspring’s linear generator, two translators transfer inside a middle response zone situated between two outer air

In Mainspring’s linear generator, two translators transfer inside a middle response zone situated between two outer air

springs. A set of stationary copper coils surrounds every translator, forming a linear electromagnetic machine (LEM).

A cycle begins with the introduction of air and gas into the middle response zone. Energy saved within the air springs

from a earlier cycle compresses the combination till a flameless response happens. The response drives the translators,

to which magnets are connected, again via the copper coils, producing electrical energy. The drive of this movement additionally

compresses the air springs, readying the system for the following cycle.MAINSPRING

It works quite like regenerative braking. An electrical automotive’s motor acts in reverse, as a generator, to transform the automotive’s movement into electrical energy, to feed the batteries. Here, the LEM converts the translator’s kinetic vitality into electrical energy.

Our management laptop instantly adjusts the move of present via the coils through an array of power-switching transistors to make the LEM apply kind of drive. The LEM can hit a desired turnaround place inside about 1/tenth of a millimeter, then goal and hit a unique turnaround place on the following cycle. The system determines a turnaround place at which the extent of compression triggers the response simply earlier than the tip of the stroke, probably the most environment friendly level.

This skill to mechanically and quickly modify compression is exceptional in two methods.

First, the generator maintains the optimum response course of all through your complete load vary, from idle all the best way to full energy, to be able to comply with demand. For instance, if energy demand drops, the gas will move extra slowly and the gas molecules will thus be slightly extra dilute; they’ll want slightly extra compression, and our system will present simply the correct quantity.

One real-world instance of the system working this manner pairs our mills with a 3.3-megawatt rooftop photo voltaic array. When the solar is shining, our mills flip off, and when the solar goes down or goes behind a cloud, our mills mechanically activate inside seconds, instantly offering exactly as a lot energy because the constructing requires.

Providing the compression that’s wanted, simply when it’s wanted, additionally unlocks the aptitude to function effectively utilizing fuels which have broadly totally different properties. For instance, hydrogen reacts with little compression, however ammonia requires lots. The linear generator is gas agnostic—it may possibly run a variety of fuels together with pure fuel, biogas, hydrogen, ammonia,

syngas, and even alcohols with out compromising efficiency.

That’s the LEM. The remaining items of the structure took place as we labored to take care of the inherent effectivity of the response in an actual machine that has minimal losses like friction and warmth switch whereas working reliably for billions of cycles.

Figuring out the generator’s design

One of the most important decisions we needed to make was the general format of the machine. We knew that the pressurized fuel needed to push on a transferring wall straight linked to an electromagnetic drive, however there have been a number of methods to make that occur. In the primary yr or so we founders, along with seven different engineers, spent many hours at a whiteboard contemplating our choices. Ultimately, we selected a symmetrical format with two translators assembly in a single, central cylinder. Our fuel-air combination, barely pressurized, enters via the holes on one finish. When the translators transfer away from that finish, these holes are uncovered, and since the contemporary combination is at barely greater stress, it flows into the cylinder, pushing the used supplies out the holes on the opposite finish.

This alternative replaces the traditional engine valve prepare—valves, seats, guides, seals, springs, rockers, camshaft, bearings, timing chain, and oil lubrication—with a easy set of holes within the cylinder wall. Another benefit of mixing two translators in a single cylinder is the discount of heat-transfer losses by practically half.

Our final main design alternative was so as to add an air chamber to both finish of the generator. As the translators transfer outward in the course of the growth portion of the cycle, the outer ends of the translators compress plain air within the outer chambers, thus storing a fraction of the response vitality. This saved vitality is recovered afterward, when the compressed air pushes the translators again towards the middle to start out the following compression cycle. It’s the identical thought as storing vitality by compressing and releasing a mechanical spring. This method, the LEMs can apply their braking forces and generate energy in each instructions, permitting us to chop their dimension by half.

We additionally let a small quantity of this pressurized air out of our system to feed air bearings. Compared with oil-lubricated bearings, air bearings have decrease friction and less complicated seals. They work similar to an air hockey sport, the place an array of small holes creates a pressurized movie of air on which the puck floats.

A prototype activates the lights

In 2012, a few yr and a half after our preliminary spherical of $10 million, we accomplished the primary prototype that generated energy. It put out just one kW.

A few days after we had gotten it to work for the primary time, one in all our buyers tell us that he was planning to drop by our Menlo Park, Calif., headquarters to see it run. The engineer who had achieved a lot of the electrical design realized that, for a demo, we would have liked a strategy to

see it making energy, so he ran out to a close-by ironmongery shop, purchased a few halogen work lights, and plugged them straight into {the electrical} bus. Though barely extra spectacular than the college science mission through which a potato powers a light-weight bulb, it proved that our design labored.

But the output was a great distance from our industrial goal, 200 kW, a quantity we had picked as a result of it will present sufficient energy for a typical retail retailer.

A much bigger model stumbles

Our subsequent milestone got here in late 2013, after we constructed a 50-kW machine. And…it didn’t work in any respect.

It had a teething drawback not unusual with massive energy gear. An array of coils switching excessive voltage at a comparatively excessive frequency generates numerous electrical noise. In our machine, it fed again to our place sensor and triggered the LEM to vibrate, making a sound we referred to as “the crunchies.” Our electrical and controls engineers have been in a position to work via the issue and eradicate it.

But then we hit a wall—actually: The facet of the translator would scrape alongside the cylinder wall every time we tried to provide quite a lot of kilowatts.

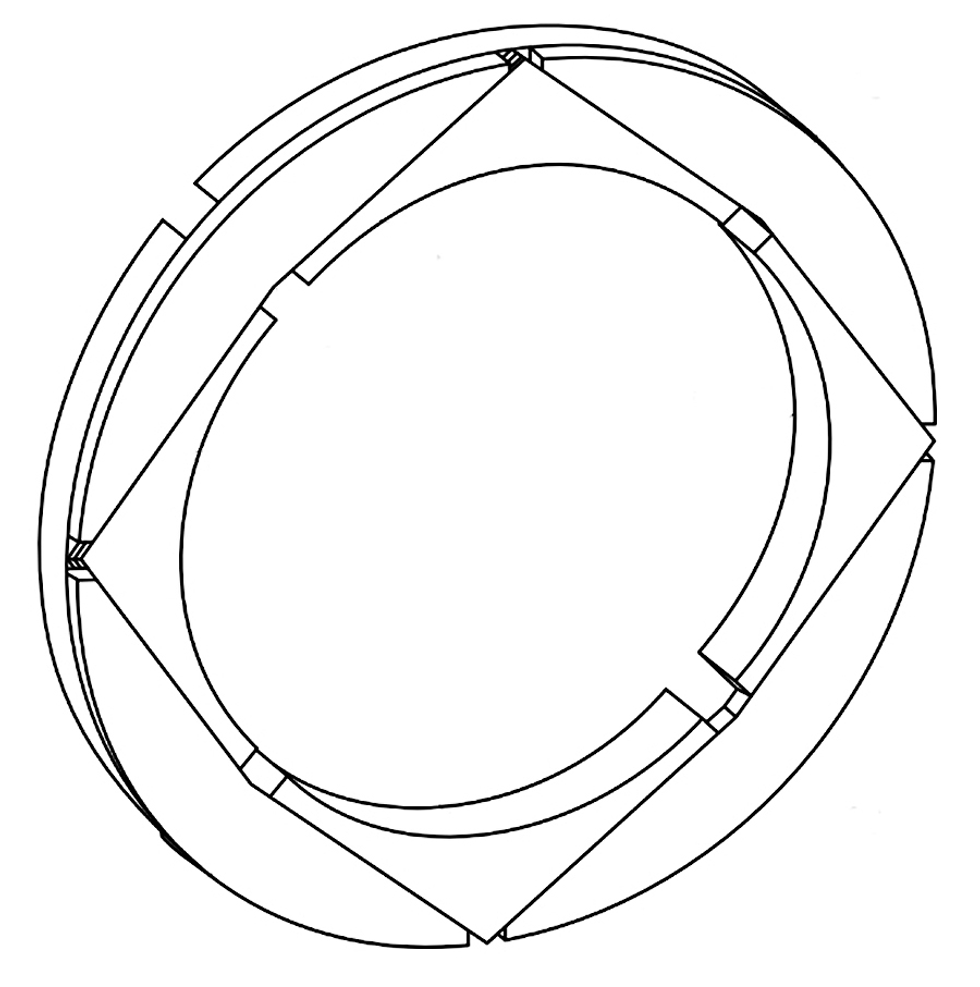

The overlapping segments in Mainspring’s patented sealing design permit the ring to take care of its effectivity even because it wears. The machine requires no added lubricant. MAINSPRING

The overlapping segments in Mainspring’s patented sealing design permit the ring to take care of its effectivity even because it wears. The machine requires no added lubricant. MAINSPRING

To clarify what occurred, I want to explain another element of our linear generator: the seal between the translator and the cylinder wall. This seal exists to maintain the pressurized fuel from escaping whereas nonetheless permitting the translator to slip.

Typically, you’ll use a layer of liquid oil between the 2 elements to keep away from friction. But bear in mind, we’re including contemporary air and gas into the cylinder via holes within the cylinder wall, and if we used a liquid lubricant on this association, it will be practically unimaginable to maintain it from stepping into the gas combine and burning in the course of the response course of, creating noxious emissions.

So we determined to develop an oil-free sealing system. It labored properly in our 1-kW machine, and so we scaled the identical design up for the 50-kW mannequin. But although the machine bought bigger, the clearance necessities stayed the identical in an absolute sense and thus have been tighter in a relative sense. That allowed tiny distortions within the elements to create factors of friction, inflicting additional distortions, ending with a runaway scraping drawback.

After months of attempting numerous tweaks, we nonetheless couldn’t run past round 20 p.c of full energy with out scraping. So we threw out the previous sealing design and began over. We ended up

inventing a singular carbon sealing-ring meeting that floats independently from the translator, one that may increase because it wears down, thus sustaining its seal.

This mounted the issue, and inside a number of extra months we have been working at full energy for a whole lot of hours. The subsequent large scaling step—from 50 kW to 100 kW—was more easy and culminated in our first official prototype, which we put in within the parking zone behind our constructing.

Making the linear generator inexpensive

We nonetheless wanted to make the linear generator inexpensive. The expertise had the benefit of utilizing fewer elements than engines or generators and missing the costly catalyst of gas cells. But we had to determine bundle design, engineering for high-volume manufacturing, and the provision chain for a product we determined would encompass two side-by-side linear mills for a complete energy of 230 kW. We made a number of errors alongside the best way.

One large one concerned our efforts to cut back the price of bodily attaching the magnet array to the surface of the translator tube. In the prototypes, we secured the magnets towards the tube by winding resin-impregnated Kevlar fiber across the outdoors of the glued-on magnets. In our first try at value discount we switched to an impregnated material wrap that went on extra shortly and simply, however after constructing a few models with this method we found that magnets have been coming free beneath the wrap. So we went again to the wound-Kevlar method, and ultimately lowered its value by growing an automatic winding course of.

Mainspring Energy’s first industrial product incorporates two linear generator cores. This unit, put in outdoors a retailer in Northern California, can produce as much as 230 kilowatts of energy.MAINSPRING

Mainspring Energy’s first industrial product incorporates two linear generator cores. This unit, put in outdoors a retailer in Northern California, can produce as much as 230 kilowatts of energy.MAINSPRING

Linear technology reaches the actual world

Finally, in June 2020, within the thick of the COVID pandemic, a crew pulled a flatbed truck as much as our Silicon Valley headquarters, loaded up the first-in-the-world manufacturing linear generator, and drove it 30 kilometers to a paying buyer’s website—a part of a nationwide retail chain. A few days later we flipped the change, and we have been in enterprise! A number of months later we delivered our second unit to a

Kroger retailer in Southern California, and shortly after {that a} pair of models went to a Lineage Logistics cold-storage facility.

When we began the corporate, we optimized the primary generator for pure fuel as a result of it was then most generally obtainable, least costly, and comparatively clear. Even although it does produce carbon emissions, our system’s effectivity makes it greener than the standard mills that it replaces.

We see our linear generator because the cornerstone of a zero-carbon grid due to its distinctive flexibility: it may possibly deal with practically any scale of energy, from single models to grid-connected arrays; it’s simply permitted and put in wherever energy is required; and it runs on nearly any gas. We have run one in all our inventory models on hydrogen and on anhydrous ammonia. We have a buyer mission working on renewable biogas in a landfill. We plan to start out working different biogas tasks at wastewater remedy vegetation and dairy waste digesters this yr. We are on the point of deploy arrays of as much as dozens of mills for large-scale operations, like electric-truck charging. And we at the moment are designing bigger, utility-scale variations within the megawatt output vary. These will all use the identical core expertise with none radical design adjustments.

And sure, Professor Edwards, we expect now we have answered that query you posted some 20 years in the past: “What is the most efficient and practical way possible to convert chemical-bond energy into useful work?” It’s the linear generator.

From Your Site Articles

Related Articles Around the Web