[ad_1]

On the positioning of a former U.S. Army Reserve base close to Boston, an uncommon construction is rising from the rolling hills.

Brandon Sorbom, the scientific director of Commonwealth Fusion Systems (CFS), leads me towards the middle of the constructing’s cross-shaped footprint, weaving amongst scaffolding, forklifts, and groups of welders and painters. Descending a stairway to a deep basement walled with 2.5-meter-thick concrete, he gestures towards a big, round gap on the middle of the room’s excessive ceiling, its edges supported by 4 stout columns.

“Within a few months, if we stick to schedule, that’s where the Sparc tokamak will nest,” Sorbom says. Surrounding a doughnut-shaped vacuum chamber, a 3-meter-tall stack of high-temperature superconducting magnets will create a robust magnetic discipline to squeeze and corral a swirling, superheated mass of hydrogen plasma. Mimicking the method that fuels the solar, the hydrogen ions—isotopes referred to as deuterium and tritium—will speed up and collide with such drive that they fuse into helium and launch extremely energetic neutrons.

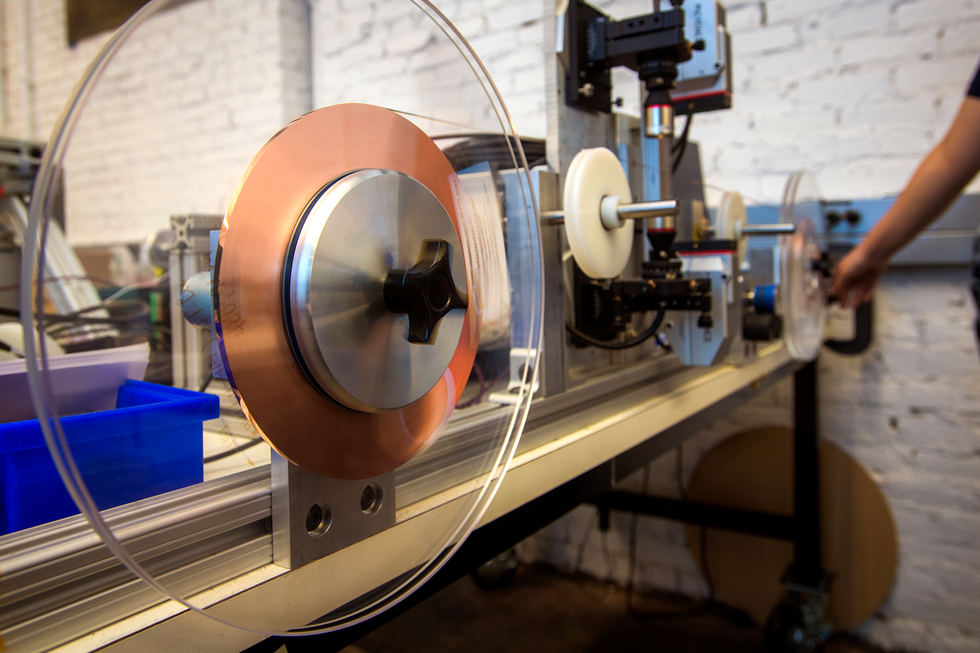

Commonwealth Fusion Systems says this spool of high-temperature superconducting tape is essential to the startup’s smaller, cheaper tokamak design. The tape is made up of yttrium barium copper oxide deposited on a metal substrate.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

Commonwealth Fusion Systems says this spool of high-temperature superconducting tape is essential to the startup’s smaller, cheaper tokamak design. The tape is made up of yttrium barium copper oxide deposited on a metal substrate.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

CFS, a startup spun out of a long time of analysis on the

Massachusetts Institute of Technology (MIT), is among the many leaders of a brand new wave of fusion-energy initiatives which have emerged previously decade, profiting from technological advances in addition to a surge in private-sector funding. Fusion-energy firms have now raised greater than US $5 billion, the vast majority of it since 2021, in response to Andrew Holland, the director of the Fusion Industry Association. These firms all intend to exhibit constructive power achieve—to get extra power out of their reactions than is used to set off them—by the tip of the last decade.

“At that point, we’ll be one step closer to a new era of carbon-free baseload electricity,” says Sorbom. “We just hope we can do it in time to be a major part of the solution to the climate crisis.”

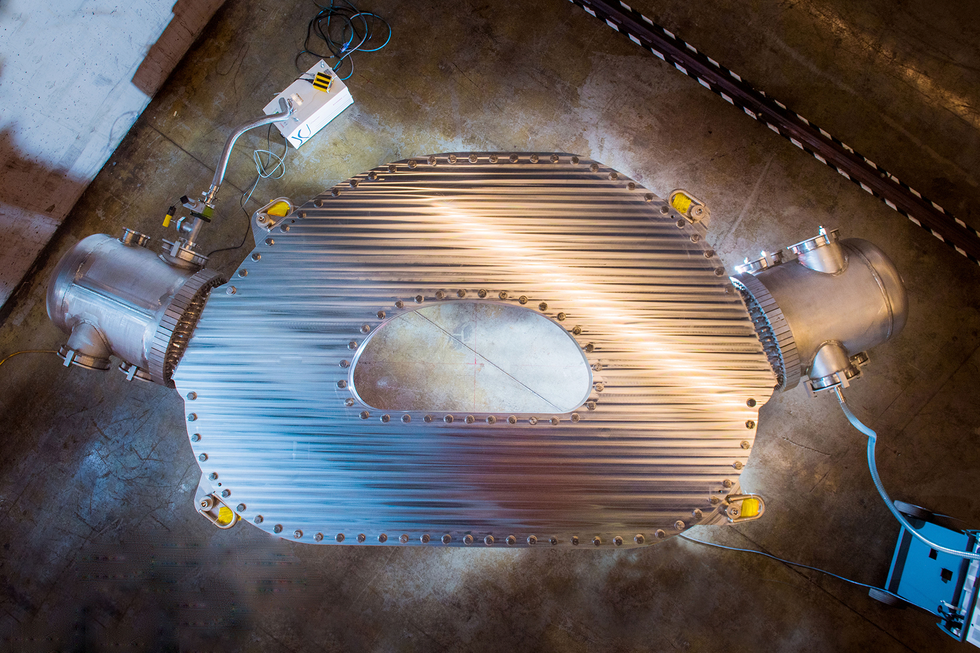

Researching, setting up, and testing Commonwealth Fusion Systems’ first magnet required the experience of 270 staff members, together with these proven right here throughout building.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

Researching, setting up, and testing Commonwealth Fusion Systems’ first magnet required the experience of 270 staff members, together with these proven right here throughout building.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

Dennis Whyte [left], the director of MIT’s Plasma Science and Fusion Center, and Commonwealth Fusion Systems’ CEO, Bob Mumgaard, confer in CFS’s take a look at corridor, the place the startup constructed and examined its first magnet.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

Dennis Whyte [left], the director of MIT’s Plasma Science and Fusion Center, and Commonwealth Fusion Systems’ CEO, Bob Mumgaard, confer in CFS’s take a look at corridor, the place the startup constructed and examined its first magnet.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

In September 2021, Commonwealth Fusion Systems examined the primary of its reactor’s D-shaped toroidal discipline magnets. The magnet demonstrated a magnetic discipline that measured 20 tesla.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

In September 2021, Commonwealth Fusion Systems examined the primary of its reactor’s D-shaped toroidal discipline magnets. The magnet demonstrated a magnetic discipline that measured 20 tesla.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

So far, Commonwealth Fusion Systems has stockpiled a couple of third of the ten,000 kilometers of high-temperature superconducting tape that it might want to full its Sparc reactor.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

So far, Commonwealth Fusion Systems has stockpiled a couple of third of the ten,000 kilometers of high-temperature superconducting tape that it might want to full its Sparc reactor.Gretchen Ertl/CFS/MIT Plasma Science and Fusion Center

What units CFS’s expertise aside is its use of high-temperature superconducting tape, which is layered and stacked to create extraordinarily sturdy electromagnets that may form and confine the unruly plasma and preserve the majority of the charged particles away from the tokamak’s partitions. The firm believes that this novel method will permit it to construct a high-performance tokamak that’s a lot smaller and cheaper than can be attainable with earlier approaches.

Icy Hot Fusion

Currently, there are two most important analysis avenues to fusion power.

Magnetic confinement makes use of electromagnets to restrict plasma, usually inside a tokamak. Inertial confinement compresses and heats a goal stuffed with gasoline—usually utilizing lasers—to kick-start a response.

Progress on each approaches is accelerating, as a result of advances each in supplies science and in high-speed computing, modeling, and simulation. Among the magnetic-confinement crowd, CFS leads the pack in fundraising, having secured

greater than $2 billion to construct its Sparc pilot plant.

In common, superconducting supplies can conduct direct-current electrical energy with out resistance and power loss when cooled beneath a crucial temperature. High-temperature superconducting (HTS) magnets, because the title suggests, can superconduct at a lot larger temperatures than the superconducting magnets historically utilized in tokamaks, which usually want extra advanced and costly cooling programs involving liquid helium. Although “high temperature” may counsel one thing that would burn you, HTS supplies function in a spread of

20 to 77 kelvins (round –200 to –250 °C). That’s nonetheless chilly, nevertheless it’s a lot hotter than what’s wanted for typical superconductors, which may solely operate at temperatures near absolute zero.

“These new materials are allowing a new path to fusion energy, because in addition to their superconducting abilities at higher cryogenic temperatures, they are also able to go to very high magnetic fields,” says

Scott Hsu, a senior advisor on the U.S. Department of Energy (DOE) and the company’s lead fusion coordinator. “These properties provide the possibility to design smaller, less complex, and lower-cost fusion systems that are quicker to build and easier to take apart for maintenance.”

Compact tokamaks like CFS’s might

reverse the developmental traits which have dominated the final 40 years of fusion power, which have fixated on constructing larger and greater machines. The largest by far is Iter, a collaborative worldwide effort to construct a large tokamak in Cadarache, France. Under building since 2013, the Iter fusion experiment (previously referred to as the International Thermonuclear Experimental Reactor) has devoured the vast majority of the world’s public funds devoted to fusion-energy analysis.The Iter Organization overseeing the challenge now estimates a $22 billion price ticket for the experiment, dwarfing the unique 2006 estimate of $5.6 billion.

“Iter is a tremendously exciting and useful experiment, but it has a size problem,” says CFS’s Sorbom. “If you could somehow shrink that tokamak, you could build it much faster and cheaper.”

But that’s not going to occur. With Iter’s long-term planning horizon and worldwide collaborative construction, it’s too far alongside to learn from the cutting-edge HTS magnets which can be permitting CFS to construct its Sparc tokamak one-fortieth the dimensions of Iter, in a fraction of the time and value.

Final Tape-Out for a Tokamak

It’s tempting to conjure a “David and Goliath” narrative out of the storyline of small firms like CFS going up towards Iter, probably the most costly science experiments of all time. But in some ways, CFS’s Sparc stands on the shoulders of Iter. The Iter challenge has drastically elevated researchers’ information about magnetic-confinement fusion and spurred the event of the trade’s extremely specialised world provide chain and workforce. Indeed, every of CFS’s six founders have labored on completely different facets of Iter and contributed to its foundational physics.

Among them is plasma physicist

Bob Mumgaard, who pioneered methods to measure the distribution {of electrical} present inside tokamak plasmas. In 2015, Mumgaard huddled with a gaggle of his fellow MIT researchers to rethink the method to fusion energy. High-temperature superconductors had been steadily enhancing since 1986, after they had been found by IBM researchers Johannes Georg Bednorz and Karl Alexander Müller—an achievement that received the pair the 1987 Nobel Prize in Physics. Since then, experiments with ceramic and rare-earth supplies and new configurations have boosted HTS efficiency and raised the temperatures at which they’ll function. This has radically improved what could be carried out with high-voltage transmission strains, MRIs, and power storage.

“With these materials finally becoming commercially available, we realized that we didn’t need to make additional physics breakthroughs,” says Mumgaard, who cofounded CFS in 2018 and is now the corporate’s CEO. “In fact, from a physicist’s standpoint, our machines look kind of boring; we’re relying on plasma physics that’s well established by Iter and other experiments. Instead, we decided to put all our risk in the magnet technology. We theorized that we could get extremely high performance through the brute force of the magnetic field.”

The staff’s superconductor of alternative was yttrium barium copper oxide, or YBCO. To make YBCO tape, some producers first use a laser to vaporize bulk YBCO right into a plume. That plume then deposits as a skinny movie of YBCO onto a metal substrate, which is adopted by an oxygenation course of to alter the YBCO’s construction right into a state that allows superconductivity.

After Sorbom’s experiments—which grew to become the premise for his doctoral thesis—confirmed that the YBCO tape might stand up to the pummeling of quick neutrons squeezed from fusing atoms, a joint MIT/CFS staff started the difficult means of buying the costly, brittle HTS tape and winding it into coils. Over two years, the staff managed to purchase up many of the world’s provide of 4-millimeter-wide HTS tape—the biggest quantity of HTS tape ever procured—sourcing it as far afield as Japan and Russia.

Technicians painstakingly wound the tape into 16 coils, which had been then assembled right into a “pancake stack” to create a toroidal discipline magnet that would encompass a piece of tokamak. In September 2021, at MIT’s

Plasma Science and Fusion Center, the staff energized the magnet and watched as the sector it produced strengthened to an intense 20 tesla—about 400,000 instances as sturdy as the standard worth for Earth’s magnetic discipline, and greater than sturdy sufficient to carry an plane service out of the water. The staff saved the magnet energized in a gentle state for about 5 hours.

“We showed that we could basically hand-build 16 winding coils and assemble them into one high-performing magnet,” says Sorbom. “But can we do that over and over again, and do it very quickly?”

To magnetize Sparc, the CFS staff might want to duplicate that feat 18 instances. Near the Sparc web site, a magnet-assembly facility is ramping up manufacturing. “We’ve cut the assembly time in half, but we’ll need to cut that time again by a factor of four to crank them out on schedule,” Sorbom says. Each of the winding packs can be constructed and examined, then built-in into toroidal discipline coils and moved to a final-assembly corridor, the place the 18 equivalent coils and surrounding constructions can be consolidated after which put in across the tokamak.

With no antecedent, CFS’s magnet-building course of represents probably the most crucial path for the entire challenge—and one that’s sophisticated by supply-chain challenges. CFS has been working to determine further suppliers within the United States, Europe, and Asia, and to develop manufacturing capabilities in-house, which can lay the groundwork for constructing fusion energy vegetation sooner or later.

Ahmed Diallo, program director for fusion packages on the DOE’s Advanced Research Projects Agency–Energy (ARPA-E), frames the HTS scarcity by way of nationwide competitiveness. “China is pushing to make 3,000 kilometers of HTS tape a year, and we’d like to be able to turn out more than 10,000 km a year to keep fusion on a fast track. Right now we are looking at novel ways to generate high-throughput manufacturing processes and also bring down the cost,” which may add $100 million or extra to the value of an HTS-magnetized tokamak.

“We’re going from making a few centimeters a year to hundreds of kilometers,” says

Guinevere Shaw, program supervisor on the DOE’s Office of Fusion Energy Sciences. “For the United States to lead in building tokamaks, we need to figure out how to leapfrog ahead with HTS production, which is a complex enterprise that very few institutions can do.”

Of the ten,000 km of tape that can be wanted for Sparc, CFS says it at present has a couple of third of it on web site, and agency orders for the remainder. After meeting, the corporate’s timeline requires the gadget to generate first plasma in late 2025, then exhibit a fusion-energy achieve issue (Q) larger than 1—in different phrases, a internet achieve, that means the fusion response produces extra power than is required to maintain it—by early 2026 on the newest. That’s an aggressive timeline, and almost each fusion challenge up to now has fallen in need of its optimistic guarantees.

And but, the plasma physics for Sparc was validated in a collection of

seven peer-reviewed papers printed within the Journal of Plasma Physics. CFS’s simulations predict that the Sparc design will produce 50 to 100 megawatts of fusion energy, reaching a Q larger than 10, which is commensurate with achieve issue projections for Iter.

From Experiments to Fusion Power Plants

As tough as will probably be, efficiently producing an power achieve of 10 or extra in a fusion experiment should show to be simpler than the next problem of utilizing nuclear fusion to place electrical energy on the grid. For the latter problem, CFS is already engaged on what the corporate says can be

the world’s first fusion energy plant. Arc, as the corporate has dubbed Sparc’s successor, can be designed to exhibit the expertise required for economically aggressive mass manufacturing of fusion energy.

“We’re doing much of the work on Arc in parallel with Sparc, so that we will have the subsystems ready, and the partners,” says Sorbom, who notes that CFS is at present engaged in dozens of collaborations with U.S. nationwide labs and universities in addition to worldwide analysis institutes.

But, not like the fusion reactions themselves—the place the physics idea is well-established, if solely partially executed—many basic questions stay unanswered relating to producing electrical energy from nuclear fusion. The engineering problem of constructing advanced programs that may harvest the power and convert it to electrical energy with out being destroyed by radiation poses a collection of tall engineering and materials-science hurdles.

Among them is a method to extract warmth from the gadget for producing electrical energy. At this level, CFS’s most popular method is to make use of a blanket of molten salt, which might additionally breed tritium (also referred to as hydrogen-3), a uncommon isotope used to gasoline magnetic confinement reactors.

Technicians set up filters in a clear room at Commonwealth Fusion Systems’ “magnet factory,” the massive constructing the place the corporate is setting up the Sparc reactor’s magnets. In the clear rooms, magnets are completed with the assistance of robots, akin to this blue one within the foreground, to take away contaminants.

Technicians set up filters in a clear room at Commonwealth Fusion Systems’ “magnet factory,” the massive constructing the place the corporate is setting up the Sparc reactor’s magnets. In the clear rooms, magnets are completed with the assistance of robots, akin to this blue one within the foreground, to take away contaminants.

CFS

A high quality technician makes use of a 3D scanner to examine a portion of one of many poloidal discipline coils throughout building. The scanner makes use of blue laser gentle to measure the construction and guarantee every part meets the magnet’s design necessities.CFS

A high quality technician makes use of a 3D scanner to examine a portion of one of many poloidal discipline coils throughout building. The scanner makes use of blue laser gentle to measure the construction and guarantee every part meets the magnet’s design necessities.CFS

The manufacturing staff wheels the work fixture for certainly one of Sparc’s toroidal discipline magnets via the 108,000-square-foot magnet manufacturing facility. Each of Sparc’s 18 toroidal discipline magnets can be constructed on prime of an analogous work fixture.

The manufacturing staff wheels the work fixture for certainly one of Sparc’s toroidal discipline magnets via the 108,000-square-foot magnet manufacturing facility. Each of Sparc’s 18 toroidal discipline magnets can be constructed on prime of an analogous work fixture.

CFS

The working design requires a repeatedly flowing loop of salt to be pumped right into a tank surrounding the plasma chamber, the place it absorbs radiated neutrons. The molten salt is then pumped outdoors the tokamak, the place its warmth power is transferred right into a fluid that drives a turbine to generate electrical energy. Because almost all the energy that Arc produces can be absorbed within the molten-salt blanket, the load on the magnet-cooling system is minimized.

The molten salt will seemingly be a combination of lithium fluoride and beryllium fluoride, generally known as FLiBe. This combo permits the salt to do double responsibility as a breeding medium during which a number of the fusion neutrons work together with lithium atoms and alter them into tritium. The tritium is then filtered out of the blanket and recycled into fusion gasoline.

FLiBe is the main focus of an ongoing analysis partnership with MIT’s Plasma Science and Fusion Center, funded by

ARPA-E. It’s certainly one of a number of DOE packages which can be pushing fusion analysis ahead with grants and pairings between personal trade and DOE’s nationwide laboratories. But whether or not FLiBe will work higher than different approaches—if in any respect—continues to be an informed guess.

The DOE-funded analysis collaboration illustrates the distinction in approaches between nations. In most nations, fusion is pursued inside government-specified improvement pathways.

“In the United States our new strategy to accelerate fusion energy R&D is to partner with the private sector, targeting public funding in ways that leverage and encourage private capital flow to a diversified portfolio of fusion technological and commercialization approaches,” says Scott Hsu of the DOE, which in May introduced $46 million in milestone-based funding to advance industrial fusion improvement through public-private partnerships.

These investments, coupled with a gentle stream of technical milestones, are boosting confidence in the potential of an accelerating time scale for fusion energy. In May, Microsoft signed the world’s

first-ever settlement to buy fusion power, from fusion startup Helion Energy. Helion’s plan for its reactor—at present underneath building—is to supply 50 MW of energy starting in 2028. And a current Fusion Industry Association survey of pros working at personal fusion firms discovered that 93 % of respondents imagine that fusion energy will start supplying electrical energy to the grid by the 2030s, up from 83 % the earlier yr.

With the results of local weather change persevering with to compound, that day can’t come quickly sufficient for Sorbom and others within the trade, who’re hoping to push their applied sciences ahead to produce clear, carbon-free power.

“Even though it’s still not happening fast enough, the progress we’ve made over the past decade feels kind of surreal,” says Sorbom. “Ten years ago, I was writing an academic paper about using HTS magnets to make fusion energy, and now we’re building them. I’m watching it happening all around me. Maybe there really is a future where we put thousands of these plants out to the world by 2050, and solve the climate crisis. That’s what I think about every time I drive into the parking lot.”

From Your Site Articles

Related Articles Around the Web