[ad_1]

In 2016, the Japanese authorities introduced a plan for the emergence of a brand new sort of society. Human civilization, the proposal defined, had begun with hunter-gatherers, handed by way of the agrarian and industrial phases, and was quick approaching the top of the data age. As then Prime Minister Shinzo Abe put it, “We are now witnessing the opening of the fifth chapter.”

This chapter, known as

Society 5.0, would see made-on-demand items and robotic caretakers, taxis, and tractors. Many of the improvements that can allow it, like synthetic intelligence, is likely to be apparent. But there may be one key know-how that’s simple to miss: lasers.

The lasers of Society 5.0 might want to meet a number of standards. They have to be sufficiently small to suit inside on a regular basis units. They have to be low-cost in order that the common metalworker or automotive purchaser can afford them—which implies they have to even be easy to fabricate and use power effectively. And as a result of this dawning period might be about mass customization (somewhat than mass manufacturing), they have to be extremely controllable and adaptive.

Semiconductor lasers would appear the right candidates, apart from one deadly flaw: They are a lot too dim. Laser brightness—outlined as optical energy per unit space per unit of stable angle—is a measure of how intensely mild may be centered because it exits the laser and the way narrowly it diverges because it strikes away. The threshold for supplies work—reducing, welding, drilling—is on the order of 1 gigawatt per sq. centimeter per steradian (GW/cm2/sr). However, the brightness of even the brightest industrial semiconductor lasers falls far under that.

Brightness can also be essential for mild detection and ranging (lidar) programs in autonomous robots and autos. These programs don’t require metal-melting energy, however to make exact measurements from lengthy distances or at excessive speeds, they do require tightly centered beams. Today’s top-line lidar programs make use of greater than 100 semiconductor lasers whose inherently divergent beams are collimated utilizing a sophisticated setup of lenses put in by hand. This complexity drives up value, placing lidar-navigated automobiles out of attain for many customers.

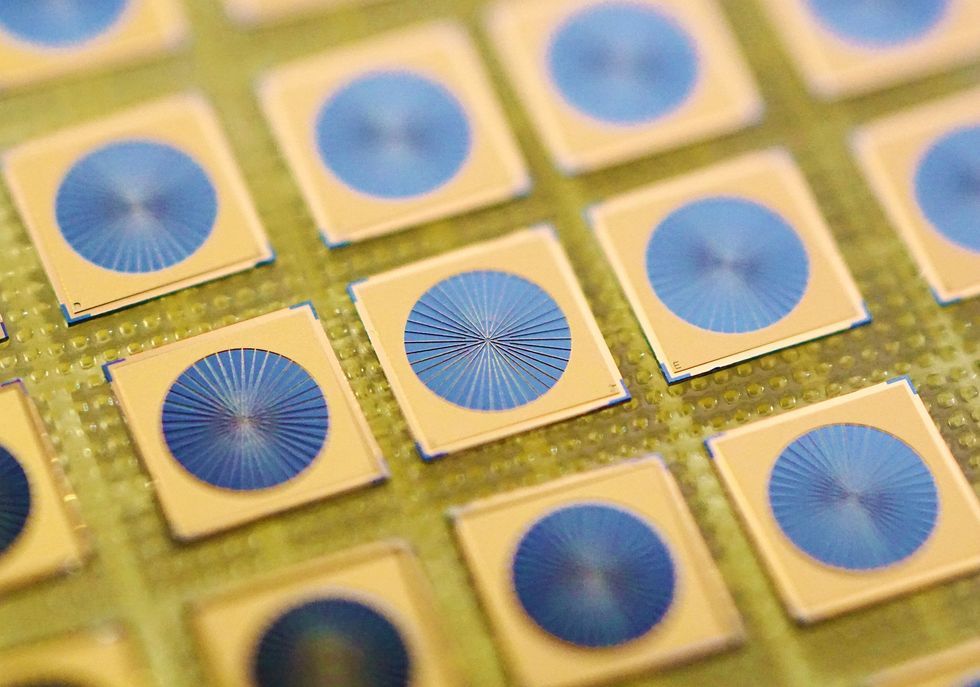

Multiple 3-millimeter-wide photonic-crystal semiconductor lasers are constructed on a semiconductor wafer. Susumu Noda

Multiple 3-millimeter-wide photonic-crystal semiconductor lasers are constructed on a semiconductor wafer. Susumu Noda

Of course, different forms of lasers can produce ultrabright beams. Carbon dioxide and

fiber lasers, as an illustration, dominate the marketplace for industrial purposes. But in comparison with speck-size semiconductor lasers, they’re huge. A high-power CO2 laser may be as giant as a fridge. They are additionally costlier, much less power environment friendly, and tougher to regulate.

Over the previous couple of a long time, our crew at Kyoto University has been growing a brand new sort of semiconductor laser that blows by way of the brightness ceiling of its standard cousins. We name it the

photonic-crystal surface-emitting laser, or PCSEL (pronounced “pick-cell”). Most lately, we fabricated a PCSEL that may be as shiny as gasoline and fiber lasers—shiny sufficient to rapidly slice by way of metal—and proposed a design for one that’s 10 to 100 occasions as shiny. Such units may revolutionize the manufacturing and automotive industries. If we, our collaborating corporations, and analysis teams all over the world—resembling at National Yang Ming Chiao Tung University, in Hsinchu, Taiwan; the University of Texas at Arlington; and the University of Glasgow—can push PCSEL brightness additional nonetheless, it might even open the door to unique purposes like inertial-confinement nuclear fusion and lightweight propulsion for spaceflight.

Hole-y Grail

The magic of PCSELs arises from their distinctive building. Like any semiconductor laser, a PCSEL consists of a skinny layer of light-generating materials, generally known as the energetic layer, sandwiched between cladding layers. In truth, for the sake of orientation, it’s useful to image the system as a literal sandwich—let’s say a slice of ham between two items of bread.

Now think about lifting the sandwich to your mouth, as in case you are about to take a chunk. If your sandwich had been a traditional semiconductor laser, its beam would radiate from the far edge, away from you. This beam is created by passing a present by way of a stripe within the energetic “ham” layer. The excited ham atoms spontaneously launch photons, which stimulate the discharge of an identical photons, amplifying the sunshine. Mirrors on every finish of the stripe then repeatedly mirror these waves; due to interference and loss, solely sure frequencies and spatial patterns—or modes—are sustained. When the acquire of a mode exceeds losses, the sunshine emerges in a coherent beam, and the laser is claimed to oscillate in that mode.

The downside with this commonplace stripe method is that it is rather tough to extend output energy with out sacrificing beam high quality. The energy of a semiconductor laser is restricted by its emission space as a result of extraordinarily concentrated mild may cause catastrophic injury to the semiconductor. You can ship extra energy by widening the stripe, which is the technique used for so-called broad-area lasers. But a wider stripe additionally provides room for the oscillating mild to take zigzag sideways paths, forming what are known as higher-order lateral modes.

You can visualize the intesity sample of a lateral mode by imagining that you simply’ve positioned a display screen within the cross part of the output beam. Light bouncing backwards and forwards completely alongside the size of the stripe kinds the basic (zero-order) mode, which has a single peak of depth within the heart of the beam. The first-order mode, from mild reflecting at an angle to the sting of the sandwich, has two peaks to the correct and left; the second-order mode, from a smaller angle, has a row of three peaks, and so forth. For every higher-order mode, the laser successfully operates as a mixture of smaller emitters whose narrower apertures trigger the beam to diverge quickly. The ensuing combination of lateral modes subsequently makes the laser mild spotty and diffuse.

Those troublesome modes are why the brightness of standard semiconductor lasers maxes out round 100 MW/cm2/sr. PCSELs cope with undesirable modes by including one other layer contained in the sandwich: the “Swiss cheese” layer. This particular additional layer is a semiconductor sheet stamped with a two-dimensional array of nanoscale holes. By tuning the spacing and form of the holes, we will management the propagation of sunshine contained in the laser in order that it oscillates in solely the basic mode, even when the emission space is expanded. The result’s a beam that may be each highly effective and slim—that’s, shiny.

Because of their inner physics, PCSELs function in a very totally different method from edge-emitting lasers. Instead of pointing away from you, as an illustration, the beam out of your PCSEL sandwich would now radiate upward, by way of the highest slice of bread. To clarify this uncommon emission, and why PCSELs may be orders of magnitude brighter than different semiconductor lasers, we should first describe the fabric properties of the Swiss cheese—if truth be told, an enchanting construction known as a photonic crystal.

How Photonic Crystals Work

Photonic crystals management the circulate of sunshine in a method that’s just like how semiconductors management the circulate of electrons. Instead of atoms, nevertheless, the lattice of a photonic crystal is sculpted out of bigger entities—resembling holes, cubes, or columns—organized such that the refractive index modifications periodically on the size of a wavelength of sunshine. Although the search to artificially assemble these marvelous supplies started lower than 40 years in the past, scientists have since discovered that they exist already in nature. Opals, peacock feathers, and a few butterfly wings, for instance, all owe their good iridescence to the intricate play of sunshine inside naturally engineered photonic crystals.

Understanding how mild strikes in a photonic crystal is key to PCSEL design. We can predict this conduct by finding out the crystal’s photonic band construction, which is analogous to the digital band construction of a semiconductor. One method to try this is to plot the connection between frequency and wavenumber—the variety of wave cycles that match inside one unit cell of the crystal’s lattice.

Consider, for instance, a easy one-dimensional photonic crystal fashioned by alternating ribbons of glass and air. Light getting into the crystal will refract by way of and partially mirror off every interface, producing overlapping beams that reinforce or weaken each other in accordance with the sunshine’s wavelength and course. Most waves will journey by way of the fabric. But at sure factors, known as singularity factors, the reflections mix completely with the incident wave to type a standing wave, which doesn’t propagate. In this case, a singularity happens when a wave undergoes precisely half a cycle from one air ribbon to the subsequent. There are different singularities wherever a unit cell is an integer a number of of half the wavelength.

One of us (Susumu Noda) started experimenting with lasers containing photonic crystal-like constructions earlier than these supplies even had a reputation. In the mid Nineteen Eighties, whereas at Mitsubishi Electric Corporation, he studied a semiconductor laser known as a distributed suggestions (DFB) laser. A DFB laser is a fundamental stripe laser with an additional inner layer containing repeatedly spaced grooves full of matter of a barely totally different refractive index. This periodic construction behaves considerably just like the 1D photonic crystal described above: It repeatedly displays mild at a single wavelength, as decided by the groove spacing, such {that a} standing wave emerges. Consequently, the laser oscillates at solely that wavelength, which is essential for long-haul fiber-optic transmission and high-sensitivity optical sensing.

As the Mitsubishi crew demonstrated, a DFB laser may be enticed to carry out different methods. For occasion, when the crew set the groove spacing equal to the lasing wavelength within the system, a number of the oscillating mild diffracted upward, inflicting the laser to shine not solely from the tiny entrance fringe of its energetic stripe but in addition from the stripe’s high. However, this floor beam fanned wildly as a result of slim width of the stripe, which additionally made it tough to extend the output energy.

To Noda’s disappointment, his crew’s makes an attempt to widen the stripe—and subsequently enhance brightness—with out inflicting different complications had been unsuccessful. Nevertheless, these early failures planted an intriguing thought: What if laser mild may very well be managed in two dimensions as an alternative of 1?

Boosting Brightness

Later, at Kyoto University, Noda led analysis into 2D and 3D photonic crystals simply as the sector was coming into being. In 1998, his crew constructed the primary PCSEL, and we now have since honed the design for varied functionalities, together with excessive brightness.

In a fundamental PCSEL, the photonic-crystal layer is a 2D sq. lattice: Each unit cell is a sq. delineated by 4 holes. Although the band construction of a 2D photonic crystal is extra sophisticated than that of a 1D crystal, it likewise reveals singularities the place we count on standing waves to type. For our units, we now have made use of the singularity that happens when the gap between neighboring holes is one wavelength. A gallium arsenide laser working at 940 nanometers, for instance, has an inner wavelength of round 280 nm (contemplating refractive index and temperature). So the holes in a fundamental gallium arsenide PCSEL could be set about 280 nm aside.

The working precept is that this: When waves of that size are generated within the energetic layer, the holes within the neighboring photonic-crystal layer act like tiny mirrors, bending the sunshine each backward and sideways. The mixed impact of a number of such diffractions creates a 2D standing wave, which is then amplified by the energetic layer. Some of this oscillating mild additionally diffracts upward and downward and leaks out the laser’s high, producing a floor beam of a single wavelength.

A key motive this design works is the massive refractive index distinction between the semiconductor and the air contained in the holes. As Noda found whereas creating the primary system, PCSELs with low refractive index contrasts, like these of DFB lasers, don’t oscillate coherently. Also not like a DFB laser, a PCSEL’s floor emission space is broad and often spherical. It can subsequently produce the next high quality beam with a lot decrease divergence.

In 2014, our group reported {that a} PCSEL with a sq. lattice of triangular holes and an emission space of 200 by 200 μm may function constantly at round 1 watt whereas sustaining a spotlike beam that diverged solely about 2 levels. Compared with standard semiconductor lasers, whose beams usually diverge greater than 30 levels, this efficiency was exceptional. The subsequent step was to spice up optical energy, for which we would have liked a bigger system. But right here we hit a snag.

According to our theoretical fashions, PCSELs utilizing the single-lattice design couldn’t develop bigger than about 200 μm with out inviting pesky higher-order lateral modes. In a PCSEL, a number of modes type when the depth of a standing wave may be distributed in a number of methods as a result of interference sample created by repeated diffractions. In the basic (learn: fascinating) mode, the depth distribution resembles Mount Fuji, with a lot of the oscillating mild concentrated within the heart of the lattice. Each higher-order mode, in the meantime, has two, three, 4, or extra Mount Fujis. So when the laser’s emission space is comparatively small, the depth peaks of the higher-order modes sit close to the lattice’s periphery. Most of their mild subsequently leaks out of the perimeters of the system, stopping these modes from oscillating and contributing to the laser beam. But as with standard lasers, enlarging the emission space makes house for extra modes to oscillate.

To clear up that downside, we added one other set of holes to the photonic-crystal layer, making a double lattice. In our most profitable model, a sq. lattice of round holes is shifted 1 / 4 wavelength from a second sq. lattice of elliptical holes. As a outcome, a number of the diffracting mild contained in the crystal interferes destructively. These cancellations trigger the depth peaks of the lateral modes to weaken and unfold. So once we broaden the laser’s emission space, mild from the higher-order modes nonetheless leaks closely and doesn’t oscillate.

Using that method, we fabricated a PCSEL with a spherical emission space 1 millimeter in diameter and confirmed it may produce a 10-W beam below steady operation. Diverging simply one-tenth of a level, the beam was even slenderer and extra collimated than its 200-μm predecessor and greater than thrice as shiny as is feasible with a traditional semiconductor laser. Our system additionally had the benefit of oscillating in a single mode, after all, which standard lasers of comparable dimension can’t do.

Pushing PCSEL brightness greater required additional innovation. At bigger diameters, the double-lattice method alone doesn’t sufficiently suppress higher-order modes, and they also oscillate but once more. We had noticed, nevertheless, that these modes depart the laser barely askew, which drew our consideration to the bottom reflector. (Picture a sheet of tinfoil lining the underside of your ham and Swiss sandwich.)

This 50-watt PCSEL is shiny sufficient to slice by way of metal.

Susumu Noda

In earlier system generations, this reflector had served merely to bounce downward-diffracted mild up and out from the laser’s emitting floor. By adjusting its place (in addition to the spacing and form of the photonic-crystal holes), we discovered we may management the reflections in order that they intrude in a helpful method with the 2D standing waves oscillating throughout the photonic-crystal layer. This interference, or coupling, basically induces the departing waves to lose a few of their power. The extra askew a departing wave, the extra mild is misplaced. And poof! No extra higher-order modes.

That is how, in 2023, we developed a PCSEL whose brightness of 1 GW/cm2/sr rivals that of gasoline and fiber lasers. With a 3-mm emission diameter, it may lase constantly at as much as 50 W whereas sustaining a beam that diverged a minuscule one-twentieth of a level. We even used it to chop by way of metal. As the brilliant, lovely beam carved a disc out of a steel plate 100 μm thick, our complete lab huddled round, watching in amazement.

More Powerful PCSELs

As spectacular because the steel-slicing demonstration was, PCSELs have to be much more highly effective to compete within the industrial market. Manufacturing vehicle elements, as an illustration, requires optical powers on the order of kilowatts.

It needs to be pretty simple to construct a PCSEL that may deal with that sort of energy—both by assembling an array of 9 3-mm PCSELs or by increasing the emission space of our present system to 1 cm. At that dimension, higher-order modes would as soon as once more emerge, lowering the beam high quality. But as a result of they’d nonetheless be as shiny as high-power gasoline and fiber lasers, such kilowatt-class PCSELs may start to usurp their bulkier rivals.

To be really game-changing, 1-cm PCSELs would wish to degree up by suppressing these higher-order modes. We have already devised a method to try this by fine-tuning the photonic-crystal construction and the place of the reflector. Although we now have not but examined this new recipe within the lab, our theoretical fashions recommend that it may elevate PCSEL brightness as excessive as 10 to 100 GW/cm2/sr. Just think about the number of distinctive and complicated merchandise that may very well be made when such concentrated mild may be wielded from a tiny bundle.

Especially for these high-power purposes, we’ll want to enhance the laser’s power effectivity and thermal administration. Even with none optimization, the “wall plug” effectivity of PCSELs is already at 30 to 40 %, exceeding most carbon-dioxide and fiber lasers. What’s extra, we’ve discovered a path we predict may result in 60 % effectivity. And as for thermal administration, the water-cooling know-how we’re utilizing within the lab right now needs to be ample for a 1,000-W, 1-cm PCSEL.

High-brightness PCSELs is also used to make smaller and extra reasonably priced sensor programs for self-driving automobiles and robots. Recently, we constructed a lidar system utilizing a 500-μm PCSEL. Under pulsed operation, we ran it at about 20 W and bought a terrifically shiny beam. Even at 30 meters, the spot dimension was solely 5 cm. Such excessive decision is unprecedented for a compact lidar system with out exterior lenses. We then mounted our prototypes—that are roughly the scale of a webcam—on robotic carts and programmed them to observe us and each other across the engineering constructing.

In a separate line of labor, we now have proven that PCSELs can emit a number of beams that may be managed electronically to level in numerous instructions. This on-chip beam steering is achieved by various the place and dimension of the holes within the photonic-crystal layer. Ultimately, it may change mechanical beam steering in lidar programs. If mild detectors had been additionally built-in on the identical chip, these all-electronic navigation programs could be critically miniature and low-cost.

Although will probably be difficult, we finally hope to make 3-cm lasers with output powers exceeding 10 kilowatts and beams shining as much as 1,000 GW/cm2/sr—brighter than any laser that exists right now. At such excessive brightness, PCSELs may change the massive, electricity-hungry CO2 lasers used to generate plasma pulses for excessive ultraviolet lithography machines, making chip manufacturing rather more environment friendly. They may equally advance efforts to appreciate nuclear fusion, a course of that includes firing trillions of watts of laser energy at a pea-size gasoline capsule. Exceptionally shiny lasers additionally elevate the potential of mild propulsion for spaceflight. Instead of taking 1000’s of years to achieve faraway stars, a probe boosted by mild may make the journey in just a few a long time.

It could also be a cliché, however we can’t consider a extra apt prediction for the subsequent chapter of human ingenuity: The future, as they are saying, is shiny.

From Your Site Articles

Related Articles Around the Web

[ad_2]