In a groundbreaking development from the University of Edinburgh, scientists have successfully engineered E. coli bacteria to convert plastic waste into paracetamol, the active ingredient in common painkillers . This remarkable process turns polyethylene terephthalate (PET) plastic—commonly found in water bottles and food packaging—into a valuable pharmaceutical product within 24 hours, achieving an impressive 92% yield with low emissions .

While E. coli has long been biotechnology’s workhorse, a new generation of scientists is asking whether we’re overlooking potentially superior microbial alternatives. As we stand on the brink of a biological revolution, the race is on to develop next-generation organisms that could transform waste into wonder more efficiently than ever before.

The Plastic-to-Painkiller Breakthrough

The Edinburgh team, led by Professor Stephen Wallace, achieved what was previously thought impossible: they merged chemistry and biology to create a sustainable manufacturing process that addresses both plastic pollution and pharmaceutical production .

The Science Behind the Innovation

The process involves several sophisticated steps:

- Plastic Breakdown: PET plastic is first broken down using sustainable chemical methods into terephthalic acid derivatives .

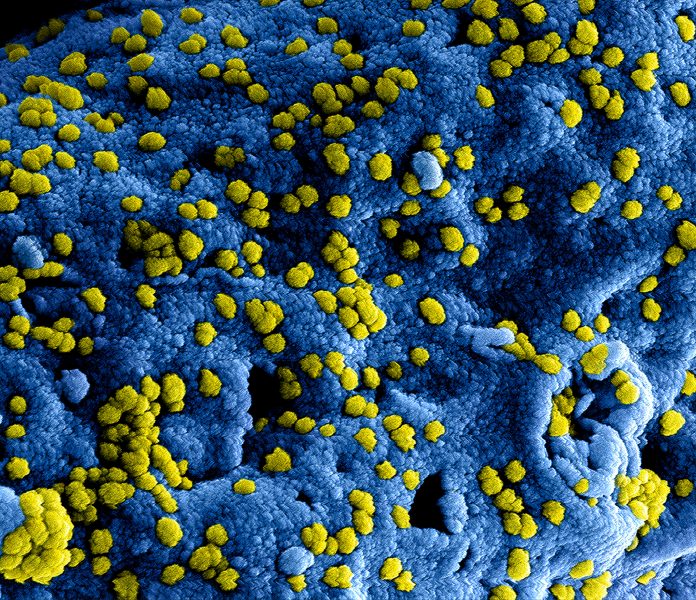

- Biological Transformation: The genetically modified E. coli then converts these derivatives into PABA (para-aminobenzoic acid) through a spontaneous chemical reaction known as a Lossen rearrangement—a process never before observed in nature .

- Final Conversion: Additional genes inserted into the bacteria (one from mushrooms and another from soil bacteria) enable the final transformation of PABA into paracetamol .

“What this technology shows is that by merging chemistry and biology in this way for the first time, we can make paracetamol more sustainably and clean up plastic waste from the environment at the same time,” Wallace explained .

E. coli: The Incumbent Workhorse

E. coli’s dominance in biotechnology stems from decades of research and development. First isolated in 1885, this bacterium became a laboratory favorite due to its fast growth and ease of manipulation . The critical breakthrough came in the 1940s when a non-pathogenic strain (K-12) demonstrated that bacteria could share and recombine genes, a discovery that earned E. coli its place as the “very favourite organism of everybody” in genetics research .

Why E. coli Reigns Supreme

- Well-understood genetics: E. coli was one of the first organisms to have its entire genome sequenced

- Robust performance: It grows predictably on various substrates and handles foreign DNA exceptionally well

- Proven industrial track record: From producing insulin to various platform chemicals, E. coli has demonstrated commercial viability

“E. coli is a natural first stage,” says Wallace. “If you want to prove something is possible with biology, it’s the obvious choice” .

The Challenger: Vibrio natriegens

While E. coli continues to be biotechnology’s go-to microbe, a powerful challenger has emerged: Vibrio natriegens (V. natriegens), a marine bacterium with extraordinary capabilities .

Advantages of V. natriegens

- Blistering growth rate: Doubles every 10 minutes—twice as fast as E. coli

- Efficient DNA uptake: Far more effective at incorporating foreign genetic material

- Natural salt tolerance: Ideal for processing high-salinity waste streams without costly desalination

Buz Barstow, a biological and environmental engineer at Cornell University, describes the capability difference as “going from a horse to a car” . His lab has spun out a company, Forage Evolution, to develop tools that make V. natriegens easier for researchers to engineer .

The Sustainability Connection

The potential applications of these engineered microbes extend far beyond pharmaceutical production:

Waste Transformation

V. natriegens shows particular promise in converting methane to valuable products, potentially turning a potent greenhouse gas into resources like animal feed or biofuels . This approach could help reduce pressure on arable land and deforestation .

Flexible Feedstock Utilization

Research has demonstrated that V. natriegens can generate electricity in microbial fuel cells using various waste streams, exhibiting remarkable feedstock flexibility . This versatility makes it ideal for processing diverse waste materials without requiring uniform, purified inputs.

Challenges on the Path to Commercialization

Despite the exciting potential, significant hurdles remain before these technologies can scale:

Technical Hurdles

- Scaling plastic breakdown: Current methods for breaking down plastic would be difficult to implement at industrial scales

- Genetic tool development: V. natriegens lacks the extensive genetic toolkit available for E. coli

- Process optimization: Moving from lab-scale proof-of-concept to cost-effective industrial production

Regulatory and Safety Considerations

The path to regulatory approval for genetically engineered organisms, especially those producing pharmaceuticals, involves rigorous scrutiny from multiple agencies . For perennial outcrossing species (which includes some microbes), the potential for gene flow to adjacent environments represents a particular biosafety concern .

The Future of Microbial Manufacturing

As we look ahead, the convergence of synthetic biology and sustainability goals suggests a promising future:

Beyond Single Applications

The same principles used to create plastic-eating bacteria could be applied to develop organisms that tackle multiple waste streams simultaneously. Imagine microbes that can process agricultural waste, plastic pollution, and industrial byproducts—all while producing valuable medicines, chemicals, and fuels.

Democratizing Biotechnology

Companies like Forage Evolution aim to make advanced genetic engineering tools more accessible, potentially enabling a wider community of researchers to contribute to sustainable biotechnology solutions .

The Innovation Imperative

As Paul Jensen, a microbiologist at the University of Michigan, cautions, our reliance on E. coli might cause us to miss out on potentially superior solutions offered by less-studied microbes . “We are just so deep with E. coli that we are not investigating enough,” he notes .

Conclusion: A Biological Revolution

The development of bacteria that can turn plastic waste into painkillers represents more than just a scientific curiosity—it signals a fundamental shift in how we approach manufacturing and waste management. By harnessing and enhancing natural biological processes, we may be entering an era where our production systems work in harmony with the environment rather than exploiting it.

As Professor Wallace optimistically notes, “Waste is just carbon, and microbes love carbon. Instead of releasing waste into the atmosphere through incineration or landfilling it, we can put it to work” .

The microscopic factories being developed in laboratories today could well become the cornerstone of a circular economy tomorrow—where waste becomes resource, pollution becomes product, and biology becomes technology’s most powerful ally.