[ad_1]

When we hear about manipulation robots in warehouses, it’s nearly at all times within the context of choosing. That is, about greedy a single merchandise from a bin of things, after which dropping that merchandise into a distinct bin, the place it could go towards constructing a buyer order. Picking a single merchandise from a jumble of things will be difficult for robots (particularly when the variety of totally different objects could also be within the tens of millions). While the issue’s actually not solved, in a well-structured and optimized setting, robots are however nonetheless getting fairly good at this type of factor.

Amazon has been on a path towards the type of robots that may decide objects since not less than 2015, when the corporate sponsored the Amazon Picking Challenge at ICRA. And only a month in the past, Amazon launched Sparrow, which it describes as “the first robotic system in our warehouses that can detect, select, and handle individual products in our inventory.” What’s necessary to know about Sparrow, nonetheless, is that like most sensible and efficient industrial robots, the system surrounding it’s doing lots of heavy lifting—Sparrow is being offered with very robot-friendly bins that makes its job far simpler than it might be in any other case. This isn’t distinctive to Amazon, and in extremely automated warehouses with robotic choosing programs it’s typical to see bins that both embrace solely an identical objects or have just some totally different objects to assist the choosing robotic achieve success.

Doing the choosing job in reverse is known as stowing, and it’s the way in which that objects get into Amazon’s warehouse workflow within the first place.

But robot-friendly bins are merely not the fact for the overwhelming majority of things in an Amazon warehouse, and an enormous a part of the rationale for that is (as per regular) people making an absolute mess of issues, on this case once they stow merchandise into bins within the first place. Sidd Srinivasa, the director of Amazon Robotics AI, described the issue of stowing objects as “a nightmare…. Stow fundamentally breaks all existing industrial robotic thinking.” But over the previous few years, Amazon Robotics researchers have put some critical work into fixing it.

First, it’s necessary to know the distinction between the robot-friendly workflows that we sometimes see with bin-picking robots, and the way in which that the majority Amazon warehouses are literally run. That is, with people doing a lot of the advanced manipulation.

You could already be conversant in Amazon’s drive items—the cell robots with cabinets on prime (referred to as pods) that autonomously drive themselves previous people who decide objects off of the cabinets to construct up orders for patrons. This is (clearly) the choosing job, however doing the identical job in reverse is known as stowing, and it’s the way in which that objects get into Amazon’s warehouse workflow within the first place. It seems that people who stow issues on Amazon’s cell cabinets achieve this in what is basically a random method with a view to maximize house most effectively. This sounds counterintuitive, nevertheless it truly makes lots of sense.

When an Amazon warehouse will get a brand new cargo of stuff, let’s say Extremely Very Awesome Nuggets (EVANs), the apparent factor to do is likely to be to name up a pod with sufficient empty cabinets to stow the entire EVANs in directly. That method, when somebody locations an order for an EVAN, the pod stuffed with EVANs exhibits up, and a human can decide an EVAN off one of many cabinets. The drawback with this methodology, nonetheless, is that if the pod stuffed with EVANs will get caught or breaks or is in any other case inaccessible, then no person can get their EVANs, slowing the complete system down (demand for EVANs being very, very excessive). Amazon’s technique is to as a substitute distribute EVANs throughout a number of pods, in order that some EVANs are at all times out there.

The course of for this distributed stow is random within the sense {that a} human stower may get a few EVANs to place into no matter pod exhibits up subsequent. Each pod has an array cabinets, a few of that are empty. It’s as much as the human to determine the place the EVANs finest match, and Amazon doesn’t actually care so long as human tells the stock system the place the EVANs ended up. Here’s what this course of appears to be like like:

https://www.youtube.com/watch?v=mXzTsk4Hxks

Two issues are instantly apparent from this video: First, the way in which that Amazon merchandise are stowed at automated warehouses like this one is completely incompatible with most present bin-picking robots. Second, it’s simple to see why this type of stowing is “a nightmare” for robots. As if the necessity to rigorously manipulate a jumble of objects to make room in a bin wasn’t a tough sufficient drawback, you additionally must cope with these elastic bands that get in the way in which of each manipulation and visualization, and you could have to have the ability to grasp and manipulate the merchandise that you just’re attempting to stow. Oof.

“For me, it’s hard, but it’s not too hard—it’s on the cutting edge of what’s feasible for robots,” says Aaron Parness, senior supervisor of utilized science at Amazon Robotics & AI. “It’s crazy fun to work on.” Parness got here to Amazon from Stanford and JPL, the place he labored on robots like StickyBot and LEMUR and was chargeable for this bonkers microspine gripper designed to understand asteroids in microgravity. “Having robots that can interact in high-clutter and high-contact environments is superexciting because I think it unlocks a wave of applications,” continues Parness. “This is exactly why I came to Amazon; to work on that kind of a problem and try to scale it.”

What makes stowing at Amazon each innovative and nightmarish for robots is that it’s a job that has been extremely optimized for people. Amazon has invested closely in human optimization, and (not less than for now) the corporate may be very reliant on people. This implies that any robotic answer that will have a big influence on the human-centered workflow might be not going to get very far. So Parness, together with Senior Applied Scientist Parker Owan, needed to develop {hardware} and software program that might clear up the issue as is. Here’s what they got here up with:

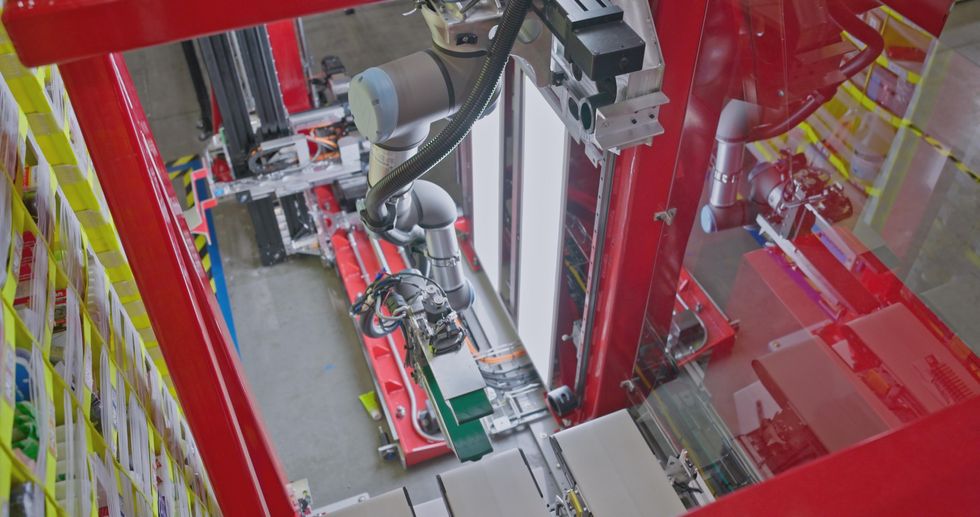

On the {hardware} facet, there’s a hook system that lifts the elastic bands out of the way in which to offer entry to every bin. But that’s the simple half; the laborious half is embodied within the end-of-arm software (EOAT), which consists of two lengthy paddles that may gently squeeze an merchandise to choose it up, with conveyor belts on their inside surfaces to shoot the merchandise into the bin. An extendable skinny steel spatula of types can go into the bin earlier than the paddles and shift objects round to make room when essential.

To use all of this {hardware} requires some very advanced software program, because the system wants to have the ability to understand the objects within the bin (which can be occluding one another and likewise behind the elastic bands), estimate the traits of every merchandise, take into account methods by which these objects may very well be safely shoved round to maximise out there bin house based mostly on the thing to be stowed, after which execute the precise motions to make all of that occur. By figuring out after which chaining collectively a collection of movement primitives, the Amazon researchers have been in a position to obtain stowing success charges (within the lab) of higher than 90 p.c.

After years of labor, the system is functioning properly sufficient that prototypes are stowing precise stock objects at an Amazon success heart in Washington state. The purpose is to have the ability to stow 85 p.c of the merchandise that Amazon shares (tens of millions of things), however because the system will be put in inside the similar workflow that people use, there’s no must hit 100%. If the system can’t deal with it, it simply passes it alongside to a human employee. This implies that the system doesn’t even want to succeed in 85 p.c earlier than it may be helpful, since if it could do even a small share of things, it could offload a few of that fundamental stuff from people. And should you’re a human who has to do lots of fundamental stuff again and again, that looks as if it is likely to be good. Thanks, robots!

But after all there’s much more happening right here on the robotics facet, and we spoke with Aaron Parness to study extra.

IEEE Spectrum: Stowing in an Amazon warehouse is a extremely human-optimized job. Does this make issues at lot tougher for robots?

Aaron Parness, senior supervisor of utilized science at Amazon Robotics & AIAmazon

Aaron Parness, senior supervisor of utilized science at Amazon Robotics & AIAmazon

Aaron Parness: In a house, in a hospital, on the house station, in these sorts of settings, you could have these human-built environments. I don’t actually suppose that’s a driver for us. The laborious drawback we’re attempting to resolve entails contact and likewise the reasoning. And that doesn’t change an excessive amount of with the setting, I don’t suppose. Most of my staff isn’t centered on questions of that nature, questions like, “If we could only make the bins this height,” or, “If we could only change this or that other small thing.” I don’t imply to say that Amazon received’t ever change processes or alter programs. Obviously, we’re doing that on a regular basis. It’s simpler to try this in new buildings than in previous buildings, however Amazon continues to be completely doing that. We simply strive to consider our product becoming into these present environments.

I believe there’s a common assertion which you could make that if you take robots from the lab and put them into the actual world, you’re at all times constrained by the setting that you just put them into. With the stowing drawback, that’s positively true. These cloth pods are horizontal surfaces, so orientation with respect to gravity generally is a issue. The elastic bands that block our view are a problem. The stiffness of the setting additionally issues, as a result of we’re doing this force-in-the-loop management, and the unbelievable range of things that Amazon sells implies that a number of the objects are compressible. So these components are half of the environment as properly. So in our case, coping with this unstructured contact, this sudden contact, that’s the toughest a part of the issue.

“Handling contact is a new thing for industrial robots, especially unexpected, unpredictable contact. It’s both a hard problem, and a worthy one.”

—Aaron Parness

What info do you could have about what’s in every bin, and the way a lot does that provide help to to stow objects?

Parness: We have the stock of what’s within the bins, and a bunch of details about every of these objects. We additionally know all of the details about the objects in our buffer [to be stowed]. And we now have a 3D illustration from our notion system. But there’s additionally a quality-control factor the place the stock system says there’s 4 objects within the bin, however in actuality, there’s solely three objects within the bin, as a result of there’s been a defect someplace. At Amazon, as a result of we’re speaking about tens of millions of things per day, that’s an everyday incidence for us.

The configuration of the objects in every bin is among the actually difficult issues. If you had the identical 5 objects: a soccer ball, a teddy bear, a T-shirt, a pair of denims, and an SD card and you set them in a bin 100 occasions, they’re going to look totally different in every of these 100 instances. You additionally get issues that may look very comparable. If you could have a crimson pair of denims or a crimson T-shirt and crimson sweatpants, your notion system can’t essentially inform which one is which. And we do have to consider probably damaging objects—our algorithm decides which objects ought to go to which bins and what confidence we now have that we’d achieve success in making that stow, together with what danger there may be that we’d injury an merchandise if we flip issues up or squish issues.

“Contact and clutter are the two things that keep me up at night.”

—Aaron Parness

How do you just remember to don’t injury something when it’s possible you’ll be working with incomplete details about what’s within the bin?

Parness: There are two issues to spotlight there. One is the strategy and the way we make our selections about what actions to take. And then the second is the right way to be sure you don’t injury objects as you do these sorts of actions, like squishing so far as you may.

With the very first thing, we use a call tree. We use that merchandise info to say all the simple stuff—if the bin is empty, put the most important factor you may within the bin. If there’s just one merchandise within the bin, and you recognize that merchandise is a e book, you may make an assumption it’s incompressible, and you may manipulate it accordingly. As you’re employed down that call tree, you get to sure branches and leaves which can be too sophisticated to have a set of heuristics, and that’s the place we use machine studying to foretell issues like, if I sweep this level cloud, how a lot house am I prone to make within the bin?

And that is the place the contact-based manipulation is available in as a result of the opposite factor is, in a warehouse, you have to have pace. You can’t stow one merchandise per hour and be environment friendly. This is the place placing power and torque within the management loop makes a distinction—we have to have a excessive charge, a few hundred hertz loop that’s closing round that sensor and a bunch of particular sauce in our admittance controller and our motion-planning stack to verify we are able to do these motions with out damaging objects.

An overhead view of Amazon’s new stowing roboticAmazon

An overhead view of Amazon’s new stowing roboticAmazon

Since you’re working in these human-optimized environments, how intently does your robotic strategy mimic what a human could be doing?

Parness: We began by doing it ourselves. We additionally did it ourselves whereas holding a robotic finish effector. And this issues rather a lot, since you don’t understand that you just’re doing all these sorts of fine-control motions, and you’ve got so many sensors in your hand, proper? This is a factor. But once we did this job ourselves, once we noticed consultants doing it, that is the place the thought of movement primitives type of emerged, which made the issue somewhat extra achievable.

What made you utilize the movement primitives strategy versus a extra generalized studying method?

Parness: I’ll provide you with an trustworthy reply—I used to be by no means tempted by reinforcement studying. But there have been some in my staff that had been tempted by that, and we had a debate, since I actually imagine in iterative design philosophy and within the worth of prototyping. We did a bunch of early-stage prototypes, attempting to make a data-driven choice, and the end-to-end reinforcement studying appeared intractable. But the motion-primitive technique truly turned me from a little bit of a skeptic about whether or not robots may even do that job, and made me suppose, “Oh, yeah, this is the thing. We got to go for this.” That was a turning level, getting these movement primitives and recognizing that that was a option to construction the issue to make it solvable, as a result of they get you a lot of the method there—you may deal with every little thing however the lengthy tail. And with the tail, possibly typically a human is trying in, and saying, “Well, if I play Tetris and I do this incredibly complicated and slow thing I can make the perfect unicorn shaped hole to put this unicorn shaped object into.” The robotic received’t do this, and doesn’t want to try this. It can deal with the majority.

You actually didn’t suppose that the issue was solvable in any respect, initially?

Parness: Yes. Parker Owan, who’s one of many lead scientists on my staff, went off into the nook of the lab and began to arrange some experiments. And I might look over there whereas engaged on different stuff, and be like, “Oh, that young guy, how brave. This problem will show him.” And then I began to get . Ultimately, there have been two issues, like I mentioned: it was discovering that you can use these movement primitives to perform the majority of the in-bin manipulation, as a result of actually that’s the toughest a part of the issue. The second factor was on the gripper, on the end-of-arm software.

“If the robot is doing well, I’m like, ‘This is achievable!’ And when we have some new problems, and then all of a sudden I’m like, ‘This is the hardest thing in the world!’ ”

—Aaron Parness

The finish effector appears to be like fairly specialised—how did you develop that?

Parness: Looking across the business, there’s lots of suction cups, lots of pinch grasps. And when you could have these sorts of grippers, unexpectedly you’re attempting to make use of the merchandise you’re gripping to govern the opposite objects which can be within the bin, proper? When we determined to go together with the paddle strategy and encapsulate the merchandise, it each gave us six levels of freedom management over the merchandise, so to verify it wasn’t going into areas we didn’t need it to, whereas additionally giving us a identified engineering floor on the gripper. Maybe I can solely predict in a common method the stiffness or the contact properties or the objects which can be within the bin, however I do know I’m touching it with the again of my paddle, which is aluminum.

But then we realized that the top effector truly takes up lots of house within the bin, and the entire level is that we’re attempting to fill these bins up in order that we are able to have lots of stuff on the market on Amazon.com. So we are saying, okay, properly, we’re going to remain outdoors the bin, however we’ll have this spatula that shall be our in-bin manipulator. It’s an excellent easy software that you need to use for pushing on stuff, flipping stuff, squashing stuff…. You’re positively not doing 27-degree-of-freedom human-hand stuff, however as a result of we now have these movement primitives, the {hardware} complemented that.

However, the paddles offered a brand new drawback, as a result of when utilizing them we principally needed to drop the merchandise after which attempt to push it in on the similar time. It was this type of dynamic—let go and shove—which wasn’t nice. That’s what led to placing the conveyor belts onto the paddles, which took us to the moon when it comes to being profitable. I’m the most important believer there may be now! Parker Owan has to type of sluggish me down typically as a result of I’m so enthusiastic about it.

It will need to have been tempting to maintain iterating on the top effector.

Parness: Yeah, it’s tempting, particularly when you could have scientists and engineers in your staff. They need every little thing. It’s at all times like, “I can make it better. I can make it better. I can make it better.” I’ve that in me too, for positive. There’s one other phrase I actually love which is simply, “so simple, it might work.” Are we inventing and complexifying, or are we making a chic answer? Are we making this simpler? Because the opposite factor that’s totally different concerning the lab and an precise success heart is that we’ve set to work with our operators. We want it to be serviceable. We want it to be accessible and simple to make use of. You can’t have 4 Ph.D.s round every of the robots always type of tinkering and optimizing it. We actually attempt to stability that, however is there a temptation? Yeah. I need to put each sensor identified to man on the robotic! That’s a temptation, however I do know higher.

To what extent is choosing simply stowing in reverse? Could you run your system backwards and have choosing solved as properly?

Parness: That’s query, as a result of clearly I take into consideration that too, however choosing is somewhat tougher. With stowing, it’s extra about the way you make house in a bin, after which the way you match an merchandise into house. For choosing, you have to establish the merchandise—when that bin exhibits up, the machine studying, the pc imaginative and prescient, that system has to have the ability to discover the precise merchandise in muddle. But as soon as we are able to deal with contact and we are able to deal with muddle, decide is for positive an software that opens up.

When I believe actually long run, if Amazon had been to deploy a bunch of those stowing robots, unexpectedly you can begin to trace objects, and you may keep in mind that this robotic stowed this merchandise on this place on this bin. You can begin to construct up container maps. Right now, although, the system doesn’t bear in mind.

Regarding choosing particularly, a pleasant factor Amazon has completed within the final couple of years is begin to have interaction with the tutorial neighborhood extra. My staff sponsors analysis at MIT and on the University of Washington. And the staff at University of Washington is definitely taking a look at choosing. Stow and decide are each actually laborious and actually interesting issues, and in time, I hope I get to resolve each!

From Your Site Articles

Related Articles Around the Web

[ad_2]