[ad_1]

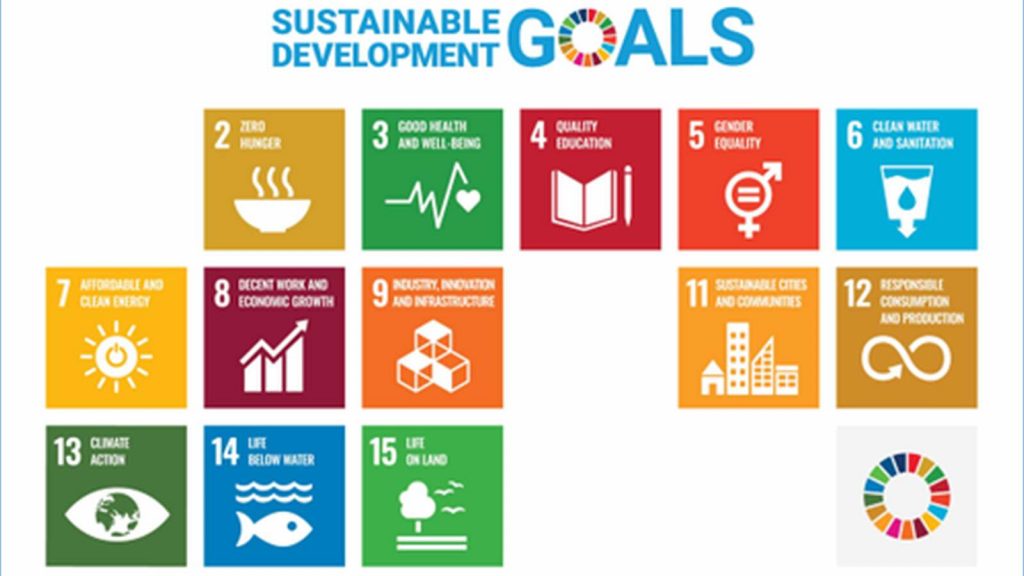

Sustainable Development Goals related for robotics

“The use of robots responds to the UN´s call for action,” says Milton Guerry, President of the International Federation of Robotics (IFR). “The IFR supports the United Nations´ sustainable development goals. There are fantastic new ways in which robots save resources and produce green technologies of the future.”

“The transformation on the way to a sustainable use of resources is proving robotics and automation to be key technologies,” says Dr Susanne Bieller, General Secretary of the International Federation of Robotics. “Intelligent automation reduces production costs: This helps battery technology achieve a breakthrough in e-mobility for example or fuel cells production for hydrogen-power as an alternative to fossil energy. At the same time, highly efficient production technology reduces CO2-emissions.”

Clean power, industrial innovation and sustainable agriculture are simply three examples which present how the usage of robots contribute to attain these UN sustainable growth objectives:

Energies of the long run – electrical energy and photo voltaic warmth – Clean Energy (UN´s SDG 7)

Pivoting away from fossil gasoline makes photo voltaic warmth and electrical energy energies of the long run: Solar panels are predicted to offer roughly a 3rd of the world’s whole electrical energy demand by 2050 – says the International Energy Agency. Heat utilization makes up for half of the world’s power utilization. Keeping tempo with this booming buyer demand for photo voltaic panels and reflectors imply with the ability to produce items in higher portions.

Solar collectors made by Absolicon © Absolicon

Industrial robots are actually used as a part of an automatic manufacturing unit manufacturing line in Sweden. Solar power firm Absolicon has developed what it sees as a gamechanger for the widespread adoption of photo voltaic warmth as an power supply: A parabolic reflector focuses the photo voltaic irradiation on a receiver and turns it into steam with a temperature of as much as 160 levels for the use in industrial manufacturing. Almost all industries require warmth for manufacturing processes. The photo voltaic collector´s emission-saving potential: each sq. meter of a photo voltaic thermal collector can produce the equal power of 100 liters of oil.

ABB robotic within the manufacturing line of Absolicon © ABB Robotics

The automation at Absolicon´s manufacturing unit in Härnösand utilizing two ABB robots has elevated manufacturing drastically. Where the corporate beforehand produced three photo voltaic collectors per day with guide manufacturing strategies, the newly put in robotic manufacturing line now has the capability to provide a completed collector each six minutes.

“Prepare-to-repair” – Industrial Innovation (UN´s SDG 9)

Prepare-to-repair is a profitable technique for robotic producers and their clients to save lots of prices and sources. This takes into consideration {that a} robotic has a mean service lifetime of as much as thirty years. Using much less components translating into decrease threat of future failure is step one of this strategy. To supply long-term restore to clients, storage of components is a problem. In order to maintain the big variety of spare components in inventory, Japanese robotic producer Fanuc e.g. runs a central warehouse for Europe. It is positioned in Luxembourg and has the scale of a soccer pitch with 600,000 spare components on inventory.

Since each hour of machine downtime prices the shopper cash, it’s oftentimes extra resource-efficient to move the spare components to the shopper and restore the machine on web site – relatively than to fabricate and ship new machines. Manufacturers like ABB, Fanuc, KUKA or Yaskawa all run devoted restore facilities the place hundreds of commercial robots are refurbished and upgraded for a second life.

“Robots eliminate chemical agents” – Smart Agriculture (UN´s SDG 2)

In agriculture, new discipline robots eradicate the usage of chemical brokers. These agricultural robots journey slowly up and down the rows of crops. Equipped with cameras and synthetic intelligence software program, they can find weeds and burn them selectively with a laser shot. The new expertise doesn’t solely utterly eradicate the usage of herbicides. Organic farmers now have an alternative choice to a associated course of referred to as “flaming” utilizing propane torches to kill weeds. Flaming may solely function earlier than crops have been planted – in any other case it could even have killed the crops.

The Fraunhofer EZRT analysis centre and companions outfitted a farming robotic with navigation expertise for mechanical weed management in sugar beets. The BlueBob 2.0 additionally does the job autonomously, in order that farmers can dedicate their time to duties with larger added worth than guide or chemical weeding. Since guide weeding is a really tedious job for people, the brand new expertise additionally helps to enhance situations of farm work. Taking over soiled, uninteresting and harmful duties is one thing robots excel at.

tags: c-Politics-Law-Society

International Federation of Robotics (IFR)

connects the world of robotics across the globe. We intention at selling the constructive advantages of robots for productiveness, competitiveness, financial development and high quality of labor and life.

International Federation of Robotics (IFR)

connects the world of robotics across the globe. We intention at selling the constructive advantages of robots for productiveness, competitiveness, financial development and high quality of labor and life.