[ad_1]

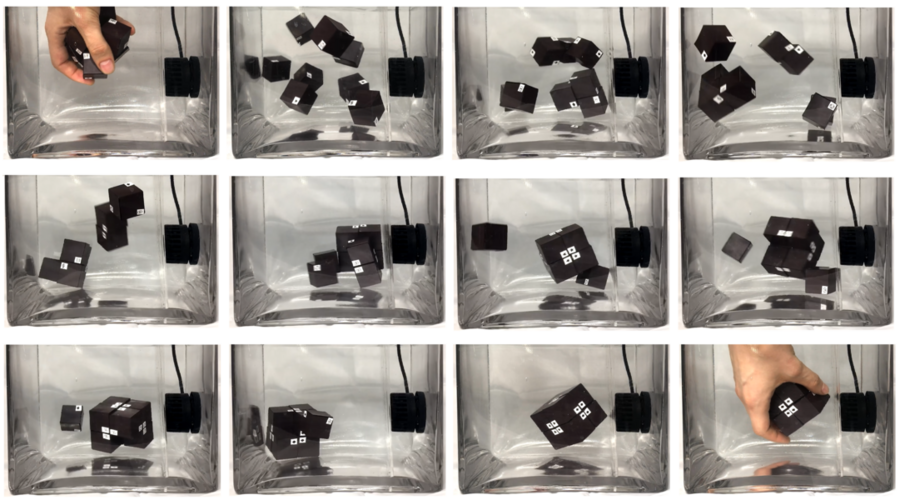

With only a random disturbance that energizes the cubes, they selectively self-assemble into a bigger block. Photos courtesy of MIT CSAIL.

By Rachel Gordon | MIT CSAIL

While automated manufacturing is ubiquitous at this time, it was as soon as a nascent discipline birthed by inventors comparable to Oliver Evans, who’s credited with creating the primary totally automated industrial course of, in flour mill he constructed and regularly automated within the late 1700s. The processes for creating automated buildings or machines are nonetheless very top-down, requiring people, factories, or robots to do the assembling and making.

However, the way in which nature does meeting is ubiquitously bottom-up; animals and vegetation are self-assembled at a mobile stage, counting on proteins to self-fold into goal geometries that encode all of the completely different features that maintain us ticking. For a extra bio-inspired, bottom-up strategy to meeting, then, human-architected supplies must do higher on their very own. Making them scalable, selective, and reprogrammable in a method that might mimic nature’s versatility means some teething issues, although.

Now, researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have tried to recover from these rising pains with a brand new methodology: introducing magnetically reprogrammable supplies that they coat completely different components with — like robotic cubes — to allow them to self-assemble. Key to their course of is a option to make these magnetic packages extremely selective about what they join with, enabling sturdy self-assembly into particular shapes and chosen configurations.

The comfortable magnetic materials coating the researchers used, sourced from cheap fridge magnets, endows every of the cubes they constructed with a magnetic signature on every of its faces. The signatures be certain that every face is selectively engaging to just one different face from all the opposite cubes, in each translation and rotation. All of the cubes — which run for about 23 cents — might be magnetically programmed at a really fantastic decision. Once they’re tossed right into a water tank (they used eight cubes for a demo), with a very random disturbance — you possibly can even simply shake them in a field — they’ll stumble upon one another. If they meet the flawed mate, they’ll drop off, but when they discover their appropriate mate, they’ll connect.

An analogy could be to think about a set of furnishings components that it’s worthwhile to assemble right into a chair. Traditionally, you’d want a set of directions to manually assemble components right into a chair (a top-down strategy), however utilizing the researchers’ methodology, these similar components, as soon as programmed magnetically, would self-assemble into the chair utilizing only a random disturbance that makes them collide. Without the signatures they generate, nevertheless, the chair would assemble with its legs within the flawed locations.

“This work is a step forward in terms of the resolution, cost, and efficacy with which we can self-assemble particular structures,” says Martin Nisser, a PhD pupil in MIT’s Department of Electrical Engineering and Computer Science (EECS), an affiliate of CSAIL, and the lead writer on a new paper concerning the system. “Prior work in self-assembly has typically required individual parts to be geometrically dissimilar, just like puzzle pieces, which requires individual fabrication of all the parts. Using magnetic programs, however, we can bulk-manufacture homogeneous parts and program them to acquire specific target structures, and importantly, reprogram them to acquire new shapes later on without having to refabricate the parts anew.”

Using the crew’s magnetic plotting machine, one can stick a dice again within the plotter and reprogram it. Every time the plotter touches the fabric, it creates both a “north”- or “south”-oriented magnetic pixel on the dice’s comfortable magnetic coating, letting the cubes be repurposed to assemble new goal shapes when required. Before plotting, a search algorithm checks every signature for mutual compatibility with all beforehand programmed signatures to make sure they’re selective sufficient for profitable self-assembly.

With self-assembly, you may go the passive or energetic route. With energetic meeting, robotic components modulate their habits on-line to find, place, and bond to their neighbors, and every module must be embedded with {hardware} for the computation, sensing, and actuation required to self-assemble themselves. What’s extra, a human or pc is required within the loop to actively management the actuators embedded in every half to make it transfer. While energetic meeting has been profitable in reconfiguring quite a lot of robotic methods, the price and complexity of the electronics and actuators have been a big barrier to scaling self-assembling {hardware} up in numbers and down in measurement.

With passive strategies like these researchers’, there’s no want for embedded actuation and management.

Once programmed and let loose below a random disturbance that provides them the vitality to collide with each other, they’re on their very own to shapeshift, with none guiding intelligence.

If you need a construction constructed from a whole bunch or hundreds of components, like a ladder or bridge, for instance, you wouldn’t need to manufacture one million uniquely completely different components, or to should re-manufacture them whenever you want a second construction assembled.

The trick the crew used towards this purpose lies within the mathematical description of the magnetic signatures, which describes every signature as a 2D matrix of pixels. These matrices be certain that any magnetically programmed components that shouldn’t join will work together to provide simply as many pixels in attraction as these in repulsion, letting them stay agnostic to all non-mating components in each translation and rotation.

While the system is at present ok to do self-assembly utilizing a handful of cubes, the crew needs to additional develop the mathematical descriptions of the signatures. In explicit, they need to leverage design heuristics that might allow meeting with very massive numbers of cubes, whereas avoiding computationally costly search algorithms.

“Self-assembly processes are ubiquitous in nature, leading to the incredibly complex and beautiful life we see all around us,” says Hod Lipson, the James and Sally Scapa Professor of Innovation at Columbia University, who was not concerned within the paper. “But the underpinnings of self-assembly have baffled engineers: How do two proteins destined to join find each other in a soup of billions of other proteins? Lacking the answer, we have been able to self-assemble only relatively simple structures so far, and resort to top-down manufacturing for the rest. This paper goes a long way to answer this question, proposing a new way in which self-assembling building blocks can find each other. Hopefully, this will allow us to begin climbing the ladder of self-assembled complexity.”

Nisser wrote the paper alongside current EECS graduates Yashaswini Makaram ’21 and Faraz Faruqi SM ’22, each of whom are former CSAIL associates; Ryo Suzuki, assistant professor of pc science on the University of Calgary; and MIT affiliate professor of EECS Stefanie Mueller, who’s a CSAIL affiliate. They will current their analysis on the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2022).

tags: c-Research-Innovation, modular

MIT News