[ad_1]

By: Erik Nieves, CEO & Co-founder of Plus One Robotics

Take a second to assume again to a world outdoors of on-line retail. You go to the big-box retailer or grocery retailer and also you do your individual selecting, packing, and delivering of products. YOU are primarily your individual success robotic. E-commerce modified that. Now, all we’re accountable for within the buying journey is clicking a button, leaving somebody (or one thing) else accountable for the very course of that customers used to do on their very own.

COVID spurred a large spike so as volumes whereas concurrently constricting labor. The result’s that the previous couple of years have introduced a wholly new class of shoppers on-line. From right here on out, the individual lugging that 40-pound sack of pet food to our doorstep received’t be the patron; it will likely be a supply individual. The development of e-commerce has outstripped labor availability, leading to a burgeoning marketplace for automation within the warehouse. At Plus One Robotics, we had already begun laying the muse for this inevitable demand, and at the moment, it’s stronger than ever.

THE LOGISTICS SECTOR SWEET SPOT

There are countless alternatives for the deployment of robotics, however whenever you boil it down, there are two sectors that would really undertake robots at scale—electronics meeting and provide chain—and solely a type of issues in North America.

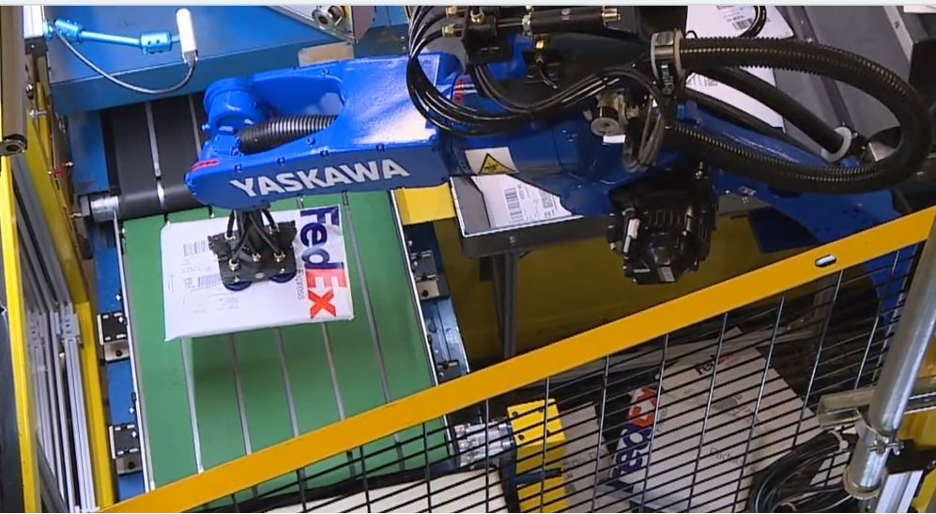

While working at Yaskawa, I frolicked attempting to pivot the one-hundred-year-old Japanese industrial firm to construct merchandise that have been going to be related within the warehouse. Once we began to dig into the logistics sector, it turned readily obvious that the warehouse is just not actually a robotic arm downside; it’s a notion and greedy downside. I made up my mind that by constructing the imaginative and prescient and grippers required for a robotic, we may assist warehouse operators optimize their processes. This realization is what in the end spurred my separation from Yaskawa in 2015, and the institution of Plus One in consequence.

ROBOTS BREAKING OUT OF THE MANUFACTURING BUBBLE

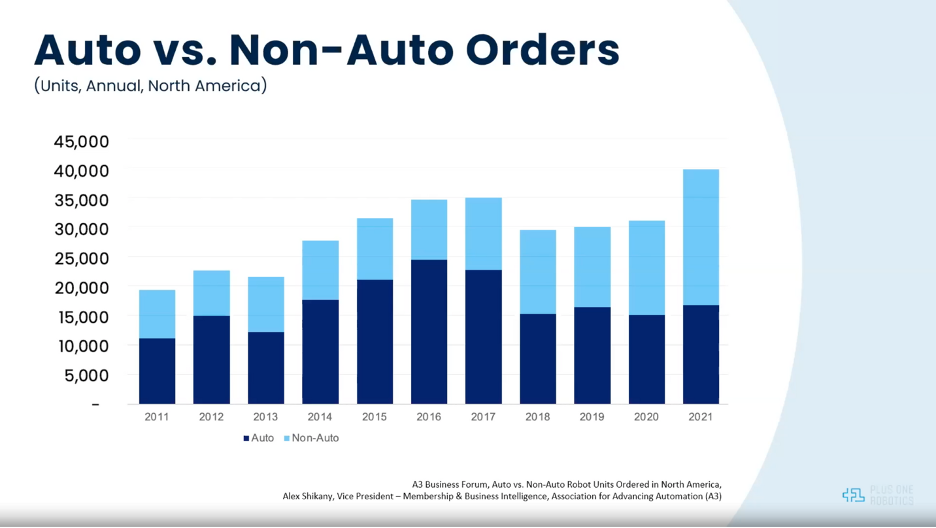

The numbers show this case. Beginning in 2018, robotic orders within the automotive trade have been successfully flat, however non-automotive orders have continued to develop. Automotive orders are for the stereotypical sturdy and dumb robotic that doesn’t require pc imaginative and prescient or AI to identify weld a automotive physique. These robots have been profitable in these roles for 40 years now, due partially to the easy necessities (energy and repeatability) and the structured atmosphere.

However, outdoors of auto factories, repeatability goes out the window and there are various extra variables to cope with. The class of non-automotive robots can embrace every part from Flippy making burgers and fries to building robots, however most of those non-automotive robotic orders are occurring inside logistics. And within the warehouse, repeatability is just not the rule. Variability is the rule.

Parcel dealing with is one such space with excessive variability. Packaging supplies and type components are altering day-after-day, and to fight this variability of parcels—and to maintain up with modifications in bundle and merchandise varieties—warehouse automation wants refined 3D sensors together with knowledge to drive AI studying.

Despite this demand, at the moment solely about 10% of warehouse operations are even partially automated. Given the latest development, a ton of jobs are left hanging and there’s not a warehouse in America that doesn’t have a “help wanted” signal outdoors. All of them are short-staffed and their churn is the best on the market.

The attrition charges at Amazon final yr have been practically 150%. If you will have a process that wants doing, you’re going to have to search out our bodies for that process—not for one shift, not for 2 shifts, however most likely for six shifts as a result of that job will preserve churning. So the place does that depart you? Looking at automation as your path ahead.

ROBOTS WORK, PEOPLE RULE

Because all warehouses at the moment are short-staffed, this isn’t a zero-sum sport of “robot in, person out.” Automation isn’t a employee discount initiative; it’s a leverage play, in order that the staff you do have might be much more productive and useful.

At Plus One, we got down to remedy the notion and greedy downside. If I choose up my cellphone off my desk, I would like my eyes, my arm, and my hand in that order. And of the three, the arm is the one one which’s an engineered commodity you’ll be able to simply go purchase. That’s what industrial manufacturing corporations like Yaskawa, Fanuc, ABB, KUKA, and Universal Robots present.

What was lacking was high-performance software program to make the most of low value, dependable 3D sensing, and greedy capabilities for warehouse robots. Plus One constructed the know-how stack, and now robots can full tedious and sometimes harmful duties like transferring packages from a bin to a conveyor belt 25+ instances a minute for six hours straight. People don’t wish to do any such job anymore, so the churn in these roles could be very excessive.

Plus One robots simply surpassed half a billion all-time picks. Our options convey collectively robotic arms, sensors, AI, and greedy know-how to ship a seamless resolution. Many of these robots incorporate human suggestions into the loop to permit for higher uptime and faster machine studying.

INVESTING IN LOGISTICS AUTOMATION

Overall, logistics and warehouse automation corporations characterize about 13% of the ROBO index portfolio at the moment, making it one of the vital necessary sectors within the ROBO portfolio by way of publicity. When you have a look at historic efficiency, you’ll be able to see that since its inception, virtually 10 years in the past now, the returns reached virtually 300% on the highs of 2021 and have witnessed a significant pullback up to now this yr. Despite this, the logistics and warehouse automation subsector has outperformed considerably and constantly.

During the pandemic, enthusiasm across the booming e-commerce sector and the businesses serving to with provide chain points and order success was predictable. The spike shouldn’t come as a shock. We’re now taking a look at this pullback as a significant alternative for buyers searching for publicity to the anticipated development in logistics automation. The ROBO Global Robotics & Automation Index (ticker: ROBO) gives diversified publicity to your complete universe of robotics, together with this sector and plenty of extra.

Erik Nieves is a founder and the CEO of Plus One Robotics, one of the vital superior robotics and pc imaginative and prescient corporations within the subject of logistics at the moment. Prior to founding Plus One, Erik was the know-how director at Yaskawa, one of the vital profitable industrial robotics corporations on the planet.