[ad_1]

|

Listen to this text |

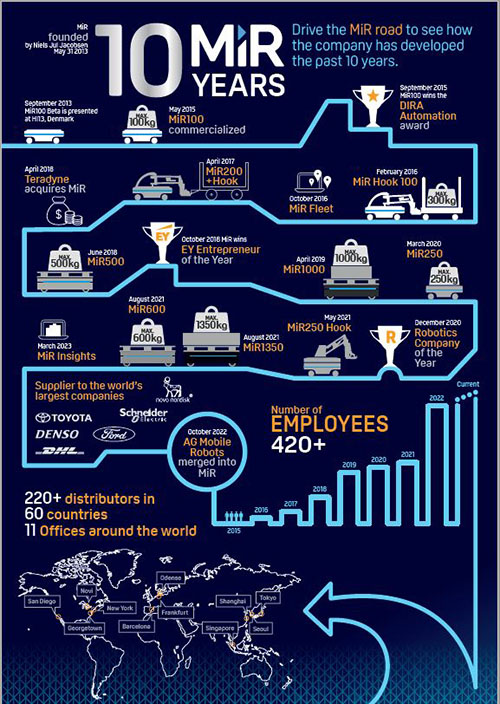

Less than a decade in the past, the thought of totally autonomous cell robots (AMRs) interacting seamlessly with human staff in warehouses and manufacturing services appeared like a futuristic imaginative and prescient. Today, hundreds of AMRs from Mobile Industrial Robots (MiR) ship components, transport completed merchandise, and deal with a number of different logistics duties with out the necessity for human operators, separate work areas, or exterior steering.

This is barely the start of what’s projected to be multi-decade development, with analysts anticipating the AMR market to have double-digit development yearly by way of at the least 2027.

“MiR was one of the early movers in the AMR industry and was visionary in developing a scalable platform of robots that could be easily deployed and integrated into factories and warehouses,” stated Ash Sharma, managing director at Interact Analysis. “It continues to innovate and has helped the industry grow from a fledgling industry to what is now, a multi-billion-dollar sector with AMRs deployed in thousands of buildings around the world.”

MiR president Jean-Pierre Hathout sees prospects now transitioning from utilizing AMRs in pilots to utilizing AMRs 24×7 in manufacturing purposes and MiR is main that transition.

“In the first 10 years of MiR’s history, we led the industry with innovative AMRs as we scaled globally with our customers,” Hathout stated. “I couldn’t be more excited about the next 10 years as we build on that innovation to provide a full range of AMR solutions on common software for our global customers. MiR has the proven products, experience and support structure to help our customers scale; and as a part of Teradyne, we are a trusted long-term supplier for mission-critical production applications.”

Founded with international ambitions

In May 2013, MiR founder Niels Jul Jacobsen got down to revolutionize the best way firms deal with their inner logistics. Thomas Visti joined him in late 2014. Both had in depth expertise from one other profitable robotics firm, Universal Robots, offering them with invaluable market insights and a transparent technique for taking the corporate from scratch to a world-leading success in just a few brief years.

In the early years, Visti was on the highway with a MiR100 robotic at the back of his automobile, giving demos to distribution companions and potential prospects. From the very starting, nevertheless, MiR targeted on a world market method primarily based on gross sales and repair through distributors and a targeted product vary. Today, MiR robots are bought by greater than 220 distributors and licensed system integrators in 60 nations. In addition to its headquarters in Odense, Denmark, MiR has regional workplaces in Boston; Holbrook, New York; San Diego; Chelmsford, Massachusetts; Georgetown, Kentucky; Singapore; Frankfurt; Barcelona; Yokohama; Seoul, and Shanghai.

An unbroken development trajectory

In April 2018, U.S.-based Teradyne acquired MiR for $272 million, additional accelerating the corporate’s place as a world market chief and offering monetary power and stability for sustained development. From simply three staff firstly of 2015, MiR at the moment employs greater than 420 folks globally, with an annual turnover of $77 million (USD) in 2022.

Large multinational firms, together with Toyota, Ikea, Novo Nordisk, Denso, DHL and Schneider Electric, account for a majority of MiR’s gross sales. A merger with AutoGuide Mobile Robots in 2022 added high-payload AMRs, furthering MiR’s technique of being a trusted provider of a full vary of AMRs to our international prospects.

A strategic deal with software program growth

In addition to repeatedly creating new AMR fashions, MiR not too long ago launched a brand new cloud-based software program device that permits fleet house owners to handle and optimize the operations of its robots by gaining actionable insights to enhance the robots’ deployment.

“As robot fleets grow, so does the demand for software tools to optimize performance and manage full fleets,” Hathout added. “If we want AMRs to be as common as forklifts and pallet lifters, it is essential that we lower the barriers for implementation, reprogramming and maintenance. We have already made substantial progress in this direction, and I firmly believe we have only glimpsed the true potential of automated logistic solutions.”

[ad_2]