[ad_1]

Modern fabrication instruments akin to 3D printers could make structural supplies in shapes that will have been troublesome or not possible utilizing typical instruments. Meanwhile, new generative design methods can take nice benefit of this flexibility to create progressive designs for elements of a brand new constructing, automotive, or nearly every other gadget.

But such “black box” automated methods typically fall wanting producing designs which might be totally optimized for his or her objective, akin to offering the best power in proportion to weight or minimizing the quantity of fabric wanted to help a given load. Fully handbook design, then again, is time-consuming and labor-intensive.

Now, researchers at MIT have discovered a strategy to obtain a few of the better of each of those approaches. They used an automatic design system however stopped the method periodically to permit human engineers to judge the work in progress and make tweaks or changes earlier than letting the pc resume its design course of. Introducing a number of of those iterations produced outcomes that carried out higher than these designed by the automated system alone, and the method was accomplished extra shortly in comparison with the totally handbook strategy.

The outcomes are reported this week within the journal Structural and Multidisciplinary Optimization, in a paper by MIT doctoral pupil Dat Ha and assistant professor of civil and environmental engineering Josephine Carstensen.

The fundamental strategy will be utilized to a broad vary of scales and purposes, Carstensen explains, for the design of all the pieces from biomedical units to nanoscale supplies to structural help members of a skyscraper. Already, automated design methods have discovered many purposes. “If we can make things in a better way, if we can make whatever we want, why not make it better?” she asks.

“It’s a way to take advantage of how we can make things in much more complex ways than we could in the past,” says Ha, including that automated design methods have already begun to be extensively used over the past decade in automotive and aerospace industries, the place lowering weight whereas sustaining structural power is a key want.

“You can take a lot of weight out of components, and in these two industries, everything is driven by weight,” he says. In some instances, akin to inner elements that aren’t seen, look is irrelevant, however for different constructions aesthetics could also be essential as properly. The new system makes it attainable to optimize designs for visible in addition to mechanical properties, and in such selections the human contact is important.

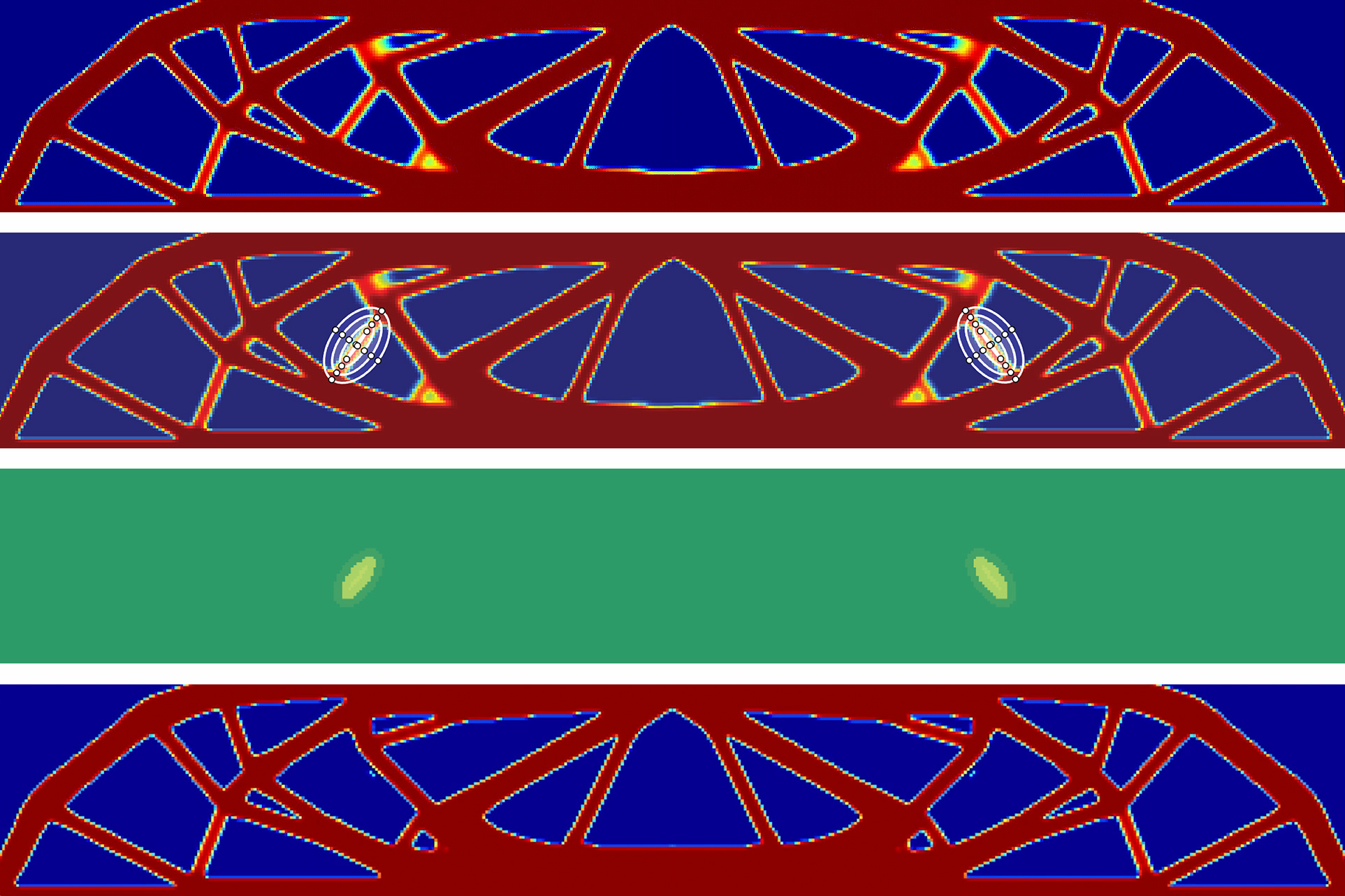

As an indication of their course of in motion, the researchers designed a lot of structural load-bearing beams, akin to is likely to be utilized in a constructing or a bridge. In their iterations, they noticed that the design has an space that would fail prematurely, so they chose that function and required this system to deal with it. The laptop system then revised the design accordingly, eradicating the highlighted strut and strengthening another struts to compensate, and resulting in an improved last design.

The course of, which they name Human-Informed Topology Optimization, begins by setting out the wanted specs — for instance, a beam must be this size, supported on two factors at its ends, and should help this a lot of a load. “As we’re seeing the structure evolve on the computer screen in response to initial specification,” Carstensen says, “we interrupt the design and ask the user to judge it. The user can select, say, ‘I’m not a fan of this region, I’d like you to beef up or beef down this feature size requirement.’ And then the algorithm takes into account the user input.”

While the outcome is just not as very best as what is likely to be produced by a totally rigorous but considerably slower design algorithm that considers the underlying physics, she says it may be significantly better than a outcome generated by a speedy automated design system alone. “You don’t get something that’s quite as good, but that was not necessarily the goal. What we can show is that instead of using several hours to get something, we can use 10 minutes and get something much better than where we started off.”

The system can be utilized to optimize a design primarily based on any desired properties, not simply power and weight. For instance, it may be used to attenuate fracture or buckling, or to scale back stresses within the materials by softening corners.

Carstensen says, “We’re not looking to replace the seven-hour solution. If you have all the time and all the resources in the world, obviously you can run these and it’s going to give you the best solution.” But for a lot of conditions, akin to designing alternative elements for tools in a conflict zone or a disaster-relief space with restricted computational energy obtainable, “then this kind of solution that catered directly to your needs would prevail.”

Similarly, for smaller firms manufacturing tools in primarily “mom and pop” companies, such a simplified system is likely to be simply the ticket. The new system they developed is just not solely easy and environment friendly to run on smaller computer systems, nevertheless it additionally requires far much less coaching to supply helpful outcomes, Carstensen says. A fundamental two-dimensional model of the software program, appropriate for designing fundamental beams and structural elements, is freely obtainable now on-line, she says, because the staff continues to develop a full 3D model.

“The potential applications of Prof Carstensen’s research and tools are quite extraordinary,” says Christian Málaga-Chuquitaype, a professor of civil and environmental engineering at Imperial College London, who was not related to this work. “With this work, her group is paving the way toward a truly synergistic human-machine design interaction.”

“By integrating engineering ‘intuition’ (or engineering ‘judgement’) into a rigorous yet computationally efficient topology optimization process, the human engineer is offered the possibility of guiding the creation of optimal structural configurations in a way that was not available to us before,” he provides. “Her findings have the potential to change the way engineers tackle ‘day-to-day’ design tasks.”