[ad_1]

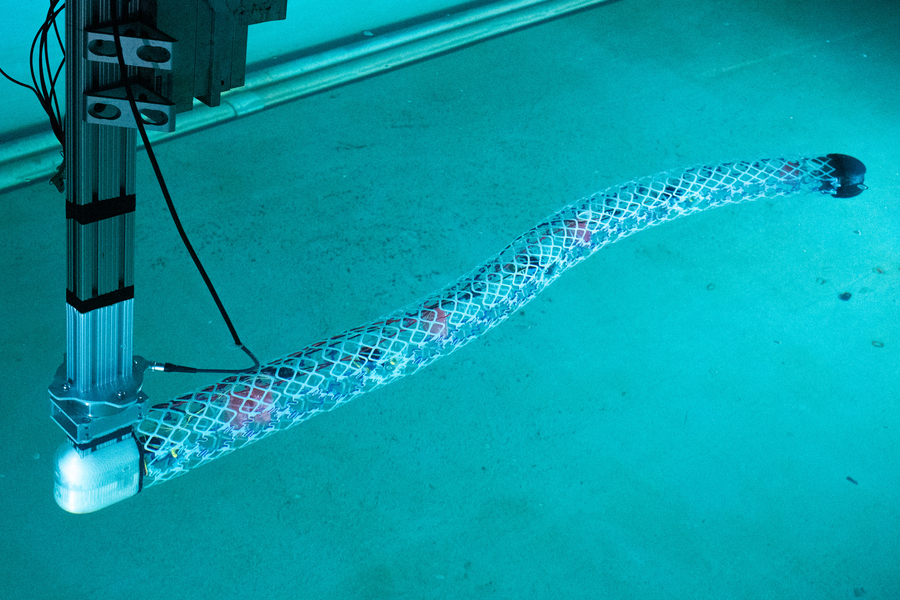

Researchers have give you an progressive method to constructing deformable underwater robots utilizing easy repeating substructures. The staff has demonstrated the brand new system in two completely different instance configurations, one like an eel, pictured right here within the MIT tow tank. Credit: Courtesy of the researchers

By David L. Chandler | MIT News Office

Underwater constructions that may change their shapes dynamically, the best way fish do, push via water far more effectively than typical inflexible hulls. But developing deformable gadgets that may change the curve of their physique shapes whereas sustaining a easy profile is a protracted and tough course of. MIT’s RoboTuna, for instance, was composed of about 3,000 completely different elements and took about two years to design and construct.

Now, researchers at MIT and their colleagues — together with one from the unique RoboTuna staff — have give you an progressive method to constructing deformable underwater robots, utilizing easy repeating substructures as an alternative of distinctive parts. The staff has demonstrated the brand new system in two completely different instance configurations, one like an eel and the opposite a wing-like hydrofoil. The precept itself, nevertheless, permits for nearly limitless variations in type and scale, the researchers say.

The work is being reported within the journal Soft Robotics, in a paper by MIT analysis assistant Alfonso Parra Rubio, professors Michael Triantafyllou and Neil Gershenfeld, and 6 others.

Existing approaches to mushy robotics for marine purposes are typically made on small scales, whereas many helpful real-world purposes require gadgets on scales of meters. The new modular system the researchers suggest may simply be prolonged to such sizes and past, with out requiring the type of retooling and redesign that will be wanted to scale up present methods.

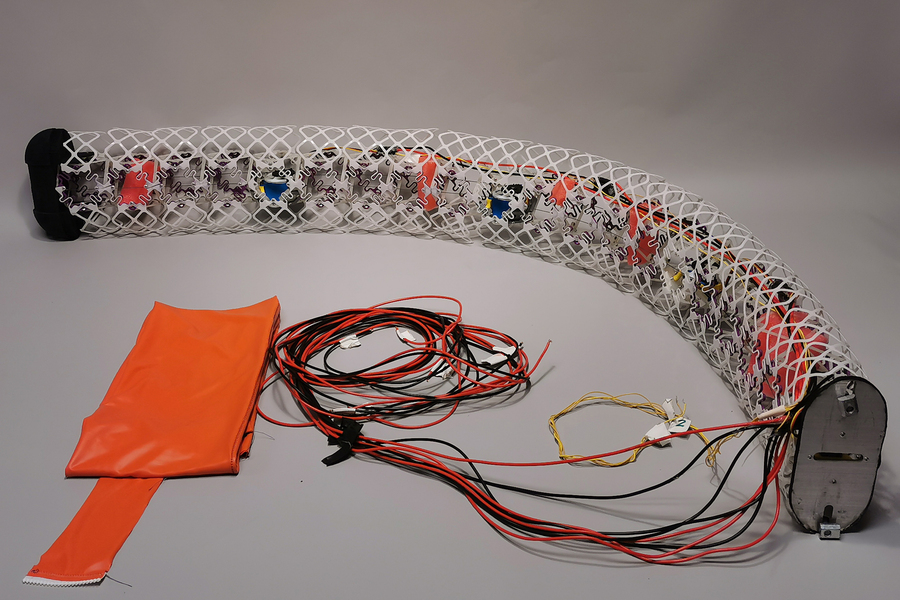

The deformable robots are made with lattice-like items, referred to as voxels, which might be low density and have excessive stiffness. The deformable robots are made with lattice-like items, referred to as voxels, which might be low density and have excessive stiffness. Credit: Courtesy of the researchers

“Scalability is a strong point for us,” says Parra Rubio. Given the low density and excessive stiffness of the lattice-like items, referred to as voxels, that make up their system, he says, “we have more room to keep scaling up,” whereas most at present used applied sciences “rely on high-density materials facing drastic problems” in shifting to bigger sizes.

The particular person voxels within the staff’s experimental, proof-of-concept gadgets are largely hole constructions made up of solid plastic items with slim struts in complicated shapes. The box-like shapes are load-bearing in a single route however mushy in others, an uncommon mixture achieved by mixing stiff and versatile parts in numerous proportions.

“Treating soft versus hard robotics is a false dichotomy,” Parra Rubio says. “This is something in between, a new way to construct things.” Gershenfeld, head of MIT’s Center for Bits and Atoms, provides that “this is a third way that marries the best elements of both.”

“Smooth flexibility of the body surface allows us to implement flow control that can reduce drag and improve propulsive efficiency, resulting in substantial fuel saving,” says Triantafyllou, who’s the Henry L. and Grace Doherty Professor in Ocean Science and Engineering, and was a part of the RoboTuna staff.

Credit: Courtesy of the researchers.

In one of many gadgets produced by the staff, the voxels are hooked up end-to-end in a protracted row to type a meter-long, snake-like construction. The physique is made up of 4 segments, every consisting of 5 voxels, with an actuator within the middle that may pull a wire hooked up to every of the 2 voxels on both aspect, contracting them and inflicting the construction to bend. The entire construction of 20 models is then lined with a rib-like supporting construction, after which a tight-fitting waterproof neoprene pores and skin. The researchers deployed the construction in an MIT tow tank to point out its effectivity within the water, and demonstrated that it was certainly able to producing ahead thrust adequate to propel itself ahead utilizing undulating motions.

“There have been many snake-like robots before,” Gershenfeld says. “But they’re generally made of bespoke components, as opposed to these simple building blocks that are scalable.”

For instance, Parra Rubio says, a snake-like robotic constructed by NASA was made up of 1000’s of distinctive items, whereas for this group’s snake, “we show that there are some 60 pieces.” And in comparison with the 2 years spent designing and constructing the MIT RoboTuna, this machine was assembled in about two days, he says.

The particular person voxels are largely hole constructions made up of solid plastic items with slim struts in complicated shapes. Credit: Courtesy of the researchers

The different machine they demonstrated is a wing-like form, or hydrofoil, made up of an array of the identical voxels however in a position to change its profile form and due to this fact management the lift-to-drag ratio and different properties of the wing. Such wing-like shapes might be used for quite a lot of functions, starting from producing energy from waves to serving to to enhance the effectivity of ship hulls — a urgent demand, as delivery is a big supply of carbon emissions.

The wing form, not like the snake, is roofed in an array of scale-like overlapping tiles, designed to press down on one another to take care of a water-proof seal even because the wing modifications its curvature. One attainable utility is likely to be in some type of addition to a ship’s hull profile that would scale back the formation of drag-inducing eddies and thus enhance its total effectivity, a risk that the staff is exploring with collaborators within the delivery trade.

The staff additionally created a wing-like hydrofoil. Credit: Courtesy of the researchers

Ultimately, the idea is likely to be utilized to a whale-like submersible craft, utilizing its morphable physique form to create propulsion. Such a craft that would evade dangerous climate by staying under the floor, however with out the noise and turbulence of typical propulsion. The idea is also utilized to elements of different vessels, similar to racing yachts, the place having a keel or a rudder that would curve gently throughout a flip as an alternative of remaining straight may present an additional edge. “Instead of being rigid or just having a flap, if you can actually curve the way fish do, you can morph your way around the turn much more efficiently,” Gershenfeld says.

The analysis staff included Dixia Fan of the Westlake University in China; Benjamin Jenett SM ’15, PhD ’ 20 of Discrete Lattice Industries; Jose del Aguila Ferrandis, Amira Abdel-Rahman and David Preiss of MIT; and Filippos Tourlomousis of the Demokritos Research Center of Greece. The work was supported by the U.S. Army Research Lab, CBA Consortia funding, and the MIT Sea Grant Program.