[ad_1]

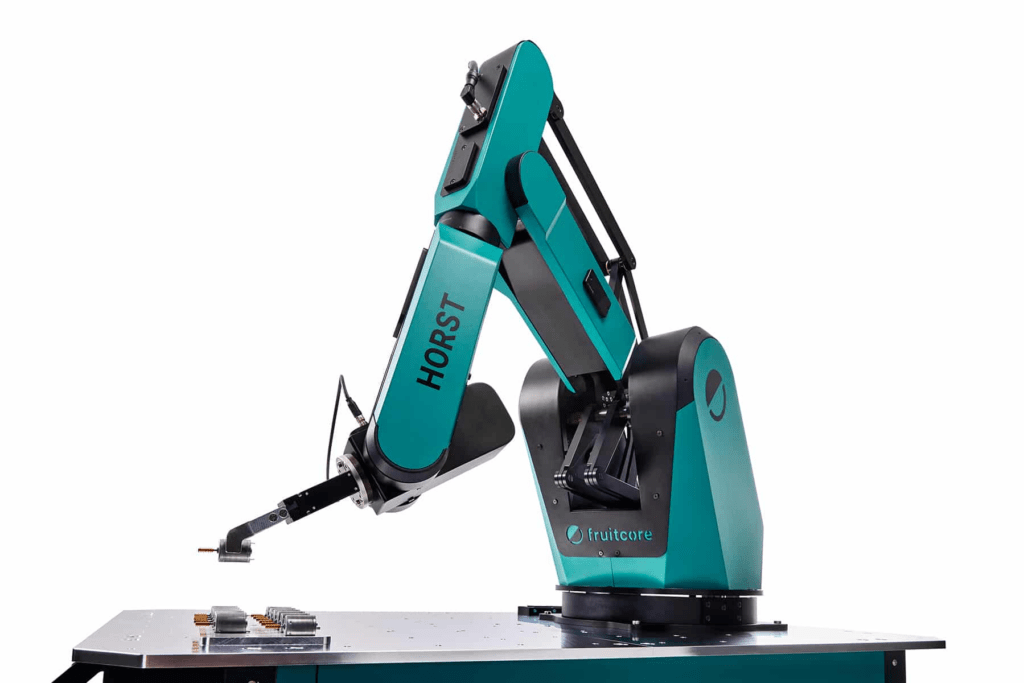

Constance, February twenty eighth, 2023 – Up to eight kilograms payload, a attain of 1,018 millimeters, quick cycle occasions: fruitcore robotics is launching HORST1000, a brand new robotic whose efficiency parameters allow a variety of further functions and higher meet the rising marketplace for industrial processes akin to machine placement and decide & place functions.

HORST1000 is a very newly developed robotic kinematics system that comes with all of the information gained from industrial apply in recent times. Building on present know-how improvements, fruitcore robotics‘ patented robotic transmission for HORST1000 has been additional optimized utilizing a machine studying algorithm, leading to a major enhance in efficiency. In phrases of design, fruitcore robotics focuses on a compact footprint and aesthetics, because it has finished with its robots which have already received a number of awards previously, such because the Fokus Open Award and the German Innovation Award. With the introduction of the brand new mannequin, the predecessor HORST900 will not be continued.

Performance enchancment based mostly on present know-how improvements

In HORST1000, key efficiency options akin to payload, vary and workspace have been considerably improved. The new all-rounder has a payload of as much as 8 kilograms and a attain of 1,018 millimeters. The builders positioned explicit concentrate on the workspace of HORST1000. The threedimensional workspace has elevated by 40 % in comparison with HORST900, permitting 50 % bigger trays to be processed. From the bottom, HORST1000 can transfer round 230 millimeters additional ahead than its predecessor, which corresponds to a 43 % longer linear path. This permits prospects to enter machines extra simply. Higher acceleration values of the person axes within the nominal load vary additionally guarantee shorter cycle occasions. In a traditional decide & place course of, this improves the cycle time by as much as 20 %.

„The technological improvements of HORST1000 allow us to additional enhance the efficiency distinction in comparison with present cobots,“ explains Jens Riegger, Managing Director (CEO) and Co-Founder of fruitcore robotics. Patrick Heimburger, Managing Director (Chief Revenue Officer) and Co-Founder of fruitcore robotics, provides: „We now permit an excellent wider vary of functions and assist our prospects implement industrial processes akin to machine placement and decide & place much more simply and effectively.“

Optimized for Machine Loading and Pick & Place

Thanks to its vary and workspace design, HORST1000 is tailored for loading and unloading any machine instruments; particularly for lathes and milling machines, the robotic can be ideally suited resulting from its software program and interfaces. The robotic can attain deep into the machines, the excessive axis accelerations allow a brief cycle time. In addition, the utmost payload of 8 kilograms additionally permits the usage of heavy instruments and sophisticated a number of gripper methods. As an automation resolution, Digital RobotHORST1000, like its predecessor HORST900 and its brothers HORST600 and HORST1400, consists of not solely highly effective and cost-effective {hardware}. It follows a coordinated working idea, which not solely makes the operation of the robotic significantly easy, but in addition the implementation of your entire software. All elements concerned within the course of, akin to grippers, CNC methods and security methods, are operated by way of the horstFX graphical consumer interface and centrally networked with the horstCOSMOS IIoT platform.

For instance, the machine software will be built-in as a 3D mannequin in horstFX and part variants will be simply traded by way of this system administration of the working software program. Switching between two instruments will be mapped on the software program facet by way of the multi-tool function. In addition to the connection to the IIoT platform, all fruitcore robotics robots include an IIoT surf stick to SIM card as commonplace. This gives corporations the chance to go surfing with the robotic system with out having to combine it into their firm community. Customers can set up an web connection as required and use horstCOSMOS to view their robotic fleet on dashboards, together with the method information of the robotic software. This permits processes to be optimized independently or in coordination with fruitcore robotics. In addition, availability is elevated as a result of upkeep will be carried out by way of predictive upkeep and a fast response will be made to service circumstances by way of distant upkeep.

Pre-orders now doable

HORST1000 will be pre-ordered from the producer any further. Delivery will happen from 01.06.2023. The value for the brand new all-rounder will be discovered on the producer’s web site.

Specifications HORST1000:

| Specification | HORST1000 |

| Max. Payload | 8 kg |

| Nominal Load | 5 kg |

| Max. Range | 1018 mm |

| Mounting Surface | 380 x 380 mm |

| Weight | Approx. 70k g |

| Repeatability | +/- 0,05 mm |

| Protection Class | IP54 |

| Sound Level | < 70 dB (A) |

| Power Supply | 230VAC, 50-60Hz, typ. 350W |

| Surrounding Temperature | 5-40 °C |

| Standard Color | RAL 5021 (Water Blue) |