[ad_1]

This sponsored article is dropped at you by COMSOL.

The 1985 action-adventure TV sequence MacGyver showcased the lifetime of Angus MacGyver, a undercover agent who solved issues utilizing objects he had available. For instance, in a single episode, he made a warmth defend out of used fridge components. In one other, he made a fishing lure with a sweet wrapper. More than three many years later, the present nonetheless has relevance. The verb MacGyver, to design one thing in a makeshift or artistic method, was added to the Oxford English Dictionary in 2015.

Try placing your MacGyver expertise to the take a look at: If you had been handed some CDs, what would you make out of them? Reflective wall artwork, mosaic ornaments, or a wind chime, maybe? What a couple of miniaturized water remedy plant?

This is what a group of engineers and researchers are doing at Eden Tech, an organization based mostly in Paris, France, that focuses on the event of microfluidics expertise. Within their R&D division, Eden Cleantech, they’re growing a compact, energy-saving water remedy system to assist deal with the rising presence of micropollutants in wastewater. To analyze the efficiency of their AKVO system (named after the Latin phrase for water, aqua), which is constructed from CDs, Eden Tech turned to multiphysics simulation.

Contaminants of Emerging Concern

“There are many ways micropollutants make it into wastewater,” says Wei Zhao, a senior chemical engineer and chief product officer at Eden Tech. The rise of those microscopic chemical compounds in wastewater worldwide is a results of day by day human actions. For occasion, after we wash our arms with cleaning soap, wipe down our sinks with cleansing provides, or flush drugs out of our our bodies, varied chemical compounds are washed down the drain and find yourself in sewage techniques. Some of those chemical compounds are categorized as micropollutants, or contaminants of rising concern (CECs). In addition to home waste, agricultural air pollution and industrial waste are additionally in charge for the rise of micropollutants in our waterways.

Micropollutants are added to the world’s lakes, rivers, and streams every single day. Many standard wastewater remedy vegetation are usually not geared up to take away these doubtlessly hazardous chemical residues from wastewater.

Unfortunately, many standard wastewater remedy vegetation (WWTP, Figure 1) are usually not designed to take away these contaminants. Therefore, they’re usually reintroduced to varied our bodies of water, together with rivers, streams, lakes, and even consuming water. Although the danger they pose to human and environmental well being will not be totally understood, the growing variety of air pollution discovered on the earth’s our bodies of water is of concern.

Figure 1. Most standard water remedy vegetation are usually not capable of take away micropollutants.

Ivan Bandura/Unsplash

With this rising downside in thoughts, Eden Tech started working on growing an answer, thus AKVO was born. Each AKVO CD core is designed to have a diameter of 15 cm and a thickness of two mm. One AKVO cartridge consists of stacked CDs of various numbers, mixed to create a miniaturized manufacturing facility. One AKVO core treats 0.5 to 2 m3 water/day, which implies that an AKVO system composed of 10,000 CDs can deal with common municipal wants. This raises the query: How can a tool constructed from CDs decontaminate water?

A Sustainable Wastewater Treatment Method

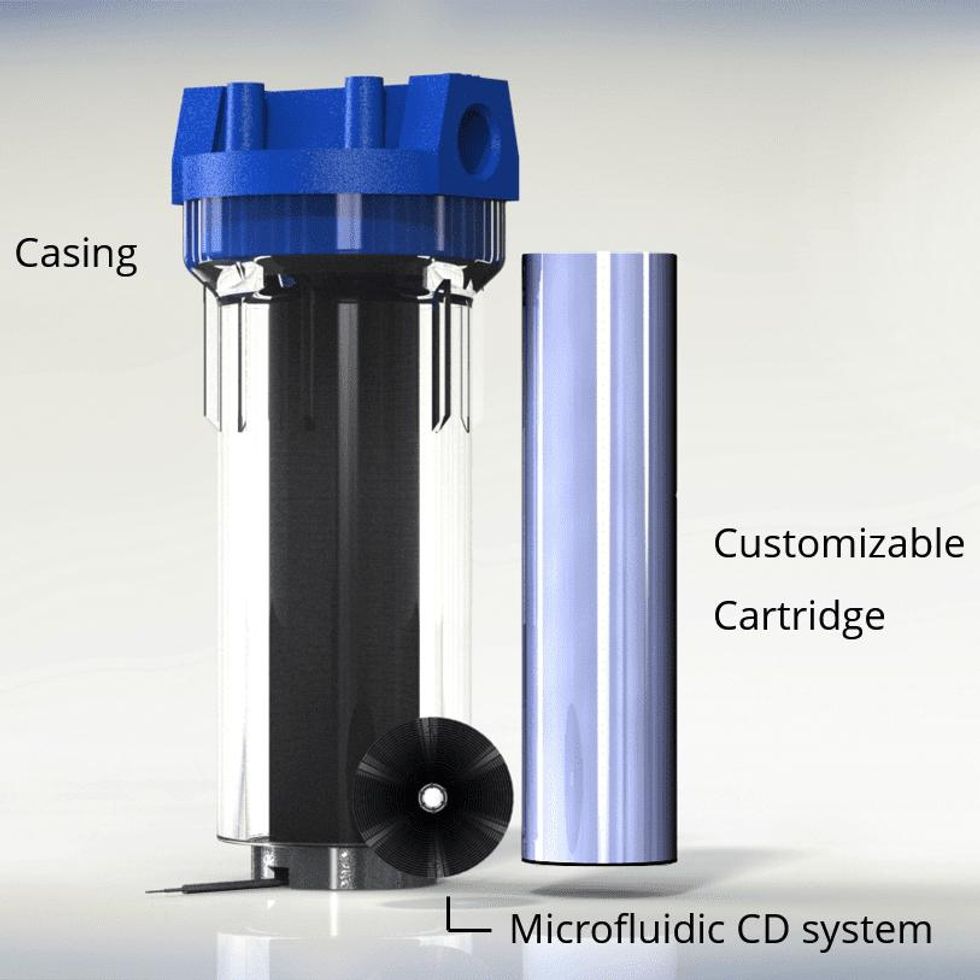

A single AKVO system (Figure 2) consists of a customizable cartridge stuffed with stacked CDs that every have a microchannel community inscribed on them. It removes undesirable components in wastewater, like micropollutants, by circulating the water in its microchannel networks. These networks are power savvy as a result of they solely require a small pump to flow into and clear giant volumes of water. The AKVO system’s cartridges can simply get replaced, with Eden Tech caring for their recycling.

Figure 2. AKVO with all of its parts labeled.

AKVO’s revolutionary design combines photocatalysis and microfluidics into one compact system. Photocatalysis, a sort of superior oxidation course of (AOP), is a quick and efficient solution to take away micropollutants from wastewater. Compared to different AOPs, it’s thought of safer and extra sustainable as a result of it’s powered by a light-weight supply. During photocatalysis, mild is absorbed by photocatalysts which have the flexibility to create electron-hole pairs, which generate free hydroxyl radicals which are capable of react with goal pollution and degrade them. The mixture of photocatalysis and microfluidics for the remedy of wastewater has by no means been performed earlier than. “It is a very ambitious project,” mentioned Zhao. “We wanted to develop an innovative method in order to provide an environmentally friendly, efficient way to treat wastewater.” AKVO’s present design didn’t come straightforward, as Zhao and his group confronted a number of design challenges alongside the way in which.

Overcoming Design Challenges

When in use, a chemical agent (catalyst) and wastewater are dispersed by AKVO’s microchannel partitions. The goal of the catalyst, titanium dioxide on this case, is to react with the micropollutants and assist take away them within the course of. However, AKVO’s quick circulate charge complicates this motion. “The big problem is that [AKVO] has microchannels with fast flow rates, and sometimes when we put the chemical agent inside one of the channels’ walls, the micropollutants in the wastewater cannot react efficiently with the agent,” mentioned Zhao. In order to extend the chance of contact between the micropollutants and the immobilized chemical agent, Zhao and his group opted to make use of a staggered herringbone micromixer (SHM) design for AKVO’s microchannel networks (Figure 3).

To analyze the efficiency of the SHM design to help chemical reactions for micropollutant degradation, Zhao used the COMSOL Multiphysics software program.

Simulating Chemical Reactions for Micropollutant Degradation

In his work, Zhao constructed two totally different fashions in COMSOL Multiphysics (Figure 4), named the Explicit Surface Adsorption (ESA) mannequin and the Converted Surface Concentration (CSC) mannequin. Both of those fashions account for chemical and fluid phenomena.

In each fashions, Zhao discovered that AKVO’s SHM construction creates vortices within the circulate shifting by it, which allows the micropollutants and the chemical agent to have an extended response interval and enhances the mass switch between every fluid layer. However, the outcomes of the ESA mannequin displayed that the design purified about 50 % of the micropollutants below remedy, fewer than what Zhao anticipated.

Unlike the ESA mannequin (Figure 5), within the CSC mannequin, it’s assumed that there isn’t any adsorption limitation. Therefore, so long as a micropollutant arrives on the floor of a catalyst, a response occurs, which has been mentioned in present literature (Ref. 1). In this mannequin, Zhao analyzed how the design carried out for the degradation of six totally different micropollutants, together with gemfibrozil, ciprofloxacin, carbamazepine, clofibric acid, bisphenol A, and acetaminophen (Figure 6). The outcomes of this mannequin had been consistent with what Zhao anticipated, with greater than 95 % of the micropollutants being handled.

“We are really satisfied with the results of COMSOL Multiphysics. My next steps will be focused on laboratory testing [of the AKVO prototype]. We are expecting to have our first prototype ready by the beginning of 2022,” mentioned Zhao. The prototype will ultimately be examined at hospitals and water remedy stations within the south of France.

Using simulation for this venture has helped the Eden Tech group save money and time. Developing a prototype of a microfluidic system, like AKVO, is expensive. To imprint microchannel networks on every of AKVO’s CDs, a microchannel photomask is required. According to Zhao, to manufacture one photomask would value about €3000 (3500 USD). Therefore, it is vitally essential that they’re assured that their system works nicely previous to its fabrication. “COMSOL Multiphysics has really helped us validate our models and our designs,” mentioned Zhao.

Pioneer within the Treatment of Micropollutants

In 2016, Switzerland launched laws mandating that wastewater remedy vegetation take away micropollutants from wastewater. Their purpose? Filter out over 80 % of micropollutants at greater than 100 Swiss WWTPs. Following their lead, many different international locations are at the moment considering of how they wish to deal with the rising presence of those contaminants of their waterways. AKVO has the potential to offer a compact, environmentally pleasant method to assist sluggish this ongoing downside.

The subsequent time you go to throw out an previous CD, or another family merchandise for that matter, ask your self: What would MacGyver do? Or, higher but: What would Eden Tech do? You is likely to be holding the constructing blocks for his or her subsequent modern design.

Reference

- C. S. Turchi, D. F. Ollis, “Photocatalytic degradation of organic water contaminants: Mechanisms involving hydroxyl radical attack,” Journal of Catalysis, Vol. 122, p. 178, 1990.

MacGyver is a registered trademark of CBS Studios Inc. COMSOL AB and its subsidiaries and merchandise are usually not affiliated with, endorsed by, sponsored by, or supported by CBS Studios Inc.