[ad_1]

Getting these clients would require abandoning the corporate’s mechanical inertial-sensor programs in favor of a brand new, unproven quartz know-how, miniaturizing the quartz sensors, and turning a producer of tens of 1000’s of costly sensors a 12 months right into a producer of thousands and thousands of cheaper ones.

Madni led an all-hands push to make that occur—and succeeded past what anybody may have imagined with

the GyroChip. This cheap inertial-measurement sensor was the primary such system to be included into cars, enabling digital stability-control (ESC) programs to detect skidding and function the brakes to forestall rollover accidents. According to the U.S. National Highway Traffic Safety Administration, within the five-year interval spanning 2011 to 2015, with ESCs being constructed into all new vehicles, the programs saved 7,000 lives within the United States alone.

The system went on to function the guts of stability-control programs in numerous business and personal plane and U.S. missile steering programs, too. It even traveled to Mars as a part of the

Pathfinder Sojourner rover.

Vital Statistics

Name: Asad M. Madni

Current job: Distinguished adjunct professor, University of California, Los Angeles; retired president, COO, and CTO, BEI Technologies

Date of start: 8 September 1947

Birthplace: Mumbai, India

Family: Wife (Taj), son (Jamal)

Education: 1968 graduate, RCA Institutes; B.S., 1969, and M.S., 1972, University of California, Los Angeles, each in electrical engineering; Ph.D., California Coast University, 1987

Patents: 39 issued, others pending

Hero: My father, total, for educating me how you can study, how you can be a human being, and the that means of affection, compassion, and empathy; in artwork, Michelangelo; in science, Albert Einstein; in engineering, Claude Shannon

Most latest guide learn:Origin by Dan Brown

Favorite books:The Prophet and The Garden of the Prophet, by Kahlil Gibran

Favorite music: In Western music, the Beatles, the Rolling Stones, Elvis Presley; in Eastern music, Ghazals

Favorite motion pictures: Contact, Good Will Hunting

Favorite cities: Los Angeles; London; Cambridge, U.Ok.; Rome

Leisure actions: Reading, climbing, listening to music

Organizational memberships: IEEE Life Fellow; U.S. National Academy of Engineering; United Kingdom Royal Academy of Engineering; Canadian Academy of Engineering

Most significant awards:IEEE Medal of Honor: “For pioneering contributions to the development and commercialization of innovative sensing and systems technologies, and for distinguished research leadership”; UCLA Engineering Alumnus of the Year 2004

For pioneering the GyroChip, and for different contributions in know-how improvement and analysis management, Madni acquired

the 2022 IEEE Medal of Honor.

Engineering wasn’t Madni’s first alternative of occupation. He wished to be a effective artist—a painter. But his household’s financial scenario in Mumbai, India (then Bombay) within the Nineteen Fifties and Sixties steered him to engineering—particularly electronics, due to his curiosity in latest improvements embodied within the pocket-size transistor radio. In 1966 he moved to the United States to review electronics at the RCA Institutes in New York City, a college created within the early 1900s to coach wi-fi operators and technicians.

“I wanted to be an engineer who would invent things,” Madni says, “one who would do things that would eventually affect humanity. Because if I couldn’t affect humanity, I felt that I would have an unfulfilling career.”

After two years finishing the electronics know-how program on the RCA Institutes, Madni went on to

the University of California, Los Angeles (UCLA), receiving a B.S. in electrical engineering in 1969. He continued on to a grasp’s and a Ph.D., utilizing digital sign processing together with frequency-domain reflectometry to investigate telecommunications programs for his dissertation analysis. While finding out, he additionally labored variously at Pacific States University as an teacher, at Beverly Hills retailer David Orgell in stock administration, and at Pertec as an engineer designing laptop peripherals.

Then, in 1975, newly engaged and on the insistence of a former classmate, he utilized for a job in Systron Donner’s microwave division.

Madni’s began at Systron Donner by designing the world’s first spectrum analyzer with digital storage. He had by no means really used a spectrum analyzer earlier than—these have been very costly devices on the time—however he knew sufficient in regards to the concept to speak himself into the job. He then spent six months working in testing, selecting up sensible expertise with the devices earlier than making an attempt to revamp one.

The mission took two years and, Madni experiences, led to 3 important patents that began his climb “to bigger and better things.” It additionally taught him, he says, an appreciation for the distinction between “what it is to have theoretical knowledge and what it is to commercialize technology that can be helpful to others.”

He went on to develop quite a few RF and microwave programs and instrumentation for the U.S. navy, together with an analyzer for communications traces and connected antennas constructed for the Navy, which turned the idea for his doctoral analysis.

Though he moved rapidly into the administration ranks, finally climbing to chairman, president, and CEO of Systron Donner, former colleagues say he by no means totally left the lab behind. His technical mark was on each mission he turned concerned in, together with the groundbreaking work that led to the GyroChip.

Before we speakabout the little quartz sensor that turned the guts of the GyroChip, right here’s somewhat background on the inertial-measurement models of the Nineties. An IMU measures a number of properties of an object: its particular drive (the acceleration that’s not as a result of gravity); its angular charge of rotation round an axis; and, typically, its orientation in three-dimensional house.

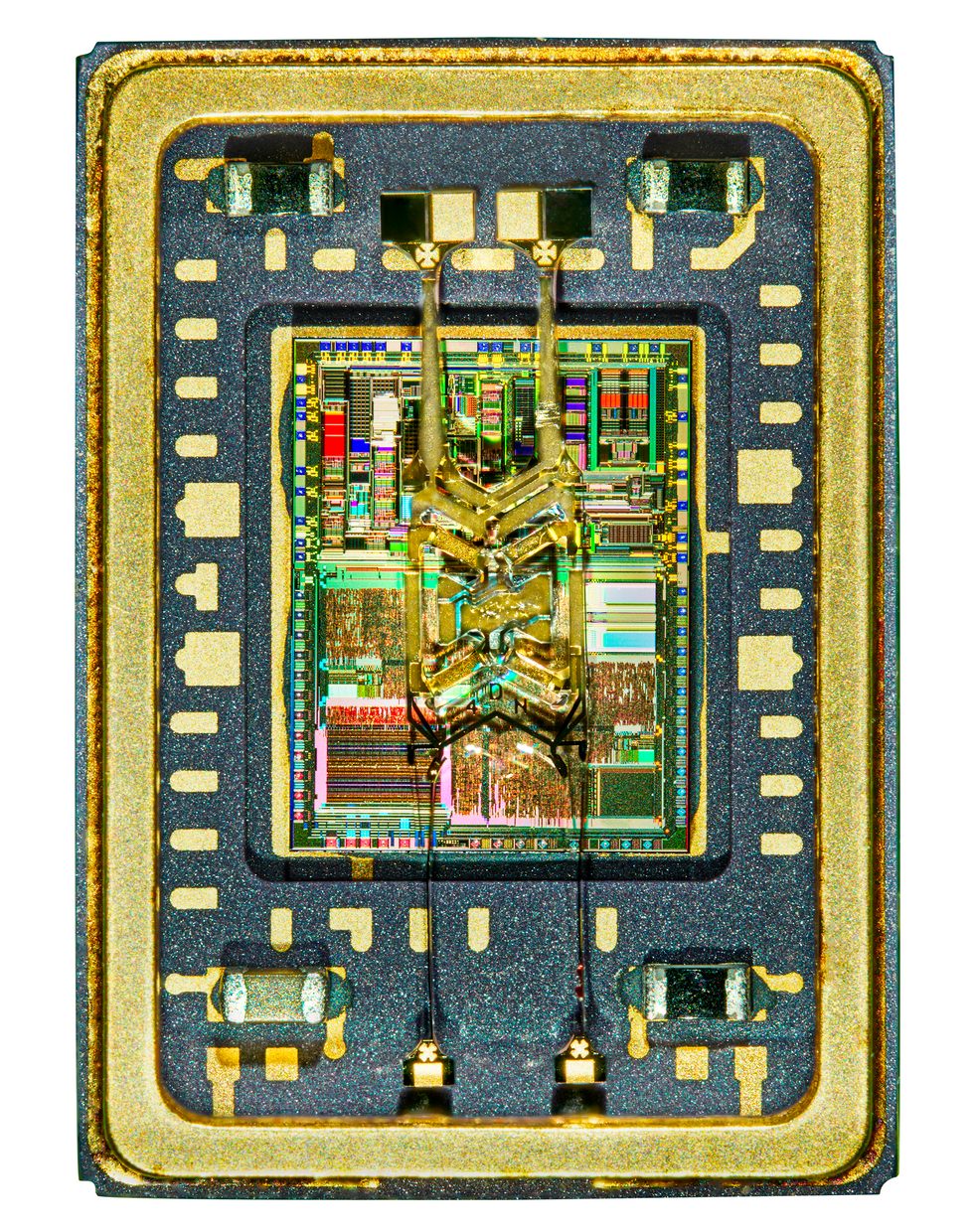

The GyroChip enabled digital stability-control programs in cars to detect skidding and prevented numerous rollover accidents. Peter Adams

The GyroChip enabled digital stability-control programs in cars to detect skidding and prevented numerous rollover accidents. Peter Adams

In the early Nineties, the standard IMU used mechanical gyroscopes for angular-rate sensing. A bundle with three extremely correct spinning mass gyroscopes was in regards to the measurement of a toaster oven and weighed a couple of kilogram. Versions that used ring-laser gyroscopes or fiber-optic gyroscopes have been considerably smaller, however all high-accuracy optical and mechanical gyros of the time price 1000’s of {dollars}.

So that was the IMU in 1990, when Systron Donner bought its defense-electronics companies to BEI Technologies, a publicly traded spinoff of BEI Electronics, itself a by-product of the venerable Baldwin Piano Co. The system was huge, heavy, costly, and held transferring mechanical components that suffered from put on and tear, affecting reliability.

Shortly earlier than the sale, Systron Donner had licensed a patent for a totally totally different sort of charge sensor from a bunch of U.S. inventors. It was little greater than a paper design on the time, Madni says, however the firm had began investing a few of its R&D finances in implementing the know-how.

The design centered on a tiny, dual-ended vibrating tuning fork carved out of quartz utilizing customary silicon-wafer-processing methods. The tines of the fork can be deflected by the Coriolis impact, the inertial drive appearing on an object because it resists being pulled from its aircraft of rotation. Because quartz has piezoelectric properties, adjustments in forces appearing upon it trigger adjustments in electrical cost. These adjustments could possibly be transformed into measurements of angular velocity.

The mission continued after Systron Donner’s divisions turned a part of BEI, and within the early Nineties BEI was manufacturing some 10,000 quartz gyroscopic sensors yearly for a categorised protection mission. But with the autumn of the Soviet Union and ensuing speedy contraction of the U.S. protection trade, Madni frightened that there can be no extra clients—at the very least for a very long time—for these tiny new sensors and even for the normal mechanical sensors that have been the principle a part of the division’s enterprise.

“We had two options,” Madni remembers. “We stick out in the sands and peacefully die, which would be a shame, because nobody else has this technology. Or we find somewhere else we can use it.”

“If I couldn’t affect humanity, I felt that I would have an unfulfilling career.”

The hunt was on. Madni says he and members of his analysis and advertising and marketing groups went to each sensors convention they may discover, speaking to anybody who used inertial sensors, no matter whether or not the functions have been industrial, business, or house. They confirmed the quartz angular-rate sensors the corporate had developed, touting their worth, precision, and reliability, and laid out a path through which the units turned smaller and cheaper in just some years. NASA was —and finally used the units within the Mars Pathfinder Sojourner rover and the programs that allowed astronauts to maneuver about in house untethered. Boeing and different plane and avionics-system producers started adopting the units.

But the automotive trade clearly represented the largest potential market. In the late Eighties, automobile corporations had begun introducing primary traction-control programs of their high-end automobiles. These programs monitored steering-wheel place, throttle place, and particular person wheel speeds, and will regulate engine velocity and braking once they detected an issue, similar to one wheel turning sooner than one other. They couldn’t, nevertheless, detect when the path of a automobile’s activate the highway didn’t match the flip of the steering wheel, a key indicator of an unstable skid that would flip right into a rollover.

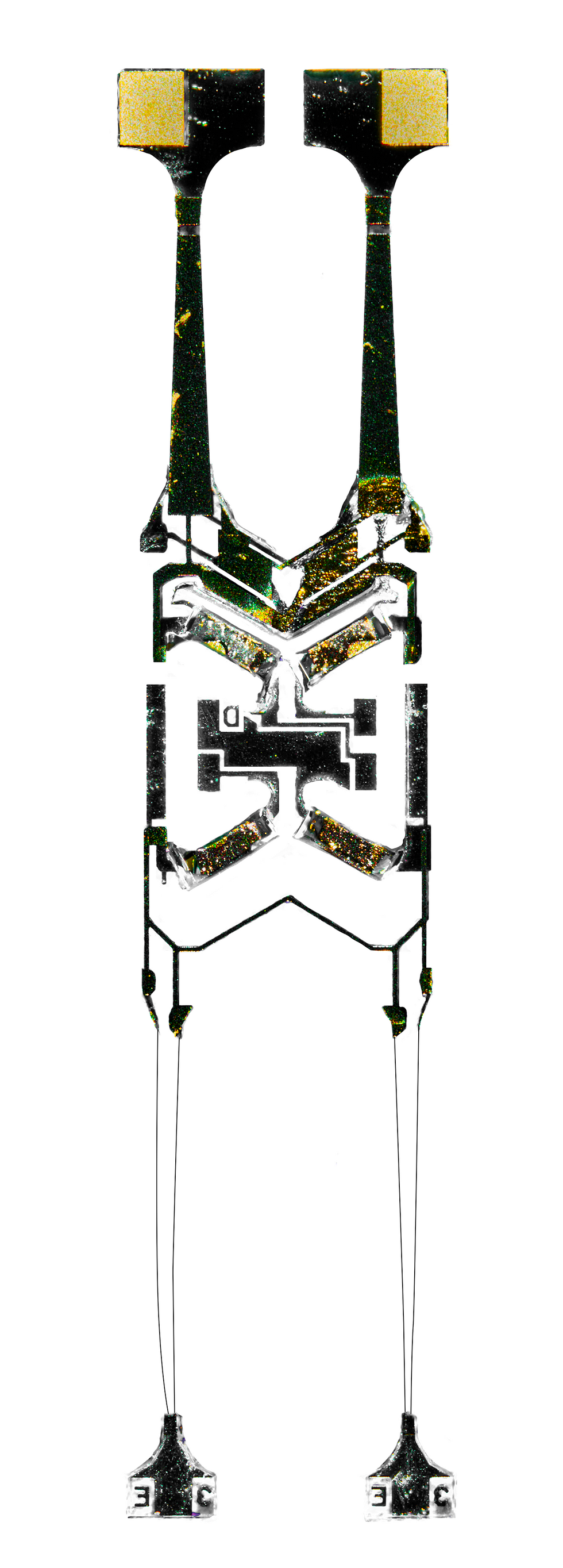

This quartz tuning fork responds to inertial forces and varieties the guts of the GyroChip.

This quartz tuning fork responds to inertial forces and varieties the guts of the GyroChip.

Peter Adams

The trade was conscious this was a deficiency, and that rollover accidents have been a major reason for deaths from auto accidents. Automotive-electronics suppliers like

Bosch have been working to develop small, dependable angular-rate sensors, largely out of silicon, to enhance traction management and rollover prevention, however none have been prepared for prime time.

Madni thought this was a market BEI may win. In partnership with

Continental Teves of Frankfurt, Germany, BEI got down to scale back the scale and value of the quartz units and manufacture them in portions remarkable within the protection trade, planning to ramp as much as thousands and thousands yearly.

This main pivot—from protection to one of the aggressive mass-market industries—would require huge adjustments for the corporate and for its engineers. Madni took the leap.

“I told the guys, ‘We are going to have to miniaturize it. We are going to have to bring the price down—from $1,200 to $1,800 per axis to $100, then to $50, and then to $25. We are going to have to sell it in hundreds of thousands of units a month and then a million and more a month.’”

To do all that, he knew that the design for a quartz-based charge sensor couldn’t have one additional part, he says. And that the manufacturing, provide chain, and even gross sales administration needed to be modified dramatically.

“I told the engineers that we can’t have anything in there other than what is absolutely needed,” Madni remembers. “And some balked—too used to engaged on advanced designs, they weren’t fascinated with doing a easy design. I attempted to elucidate to them that what I used to be asking them to do was

extra tough than the advanced issues they’ve carried out,” he says. But he nonetheless misplaced some high-level design engineers.

“The board of directors asked me what I was doing, [saying] that those were some of our best people. I told them that it wasn’t a question of the best people; if people are not going to adapt to the current needs, what good do they do?”

Peter Adams

Peter Adams

Others have been prepared to adapt, and he despatched a few of these engineers to go to watch producers in Switzerland to find out about dealing with quartz; the watch trade had been utilizing the fabric for many years. And he supplied others coaching by consultants within the automotive trade, to find out about its operations and necessities.

The adjustments wanted weren’t straightforward, Madni remembers. “We have a lot of scars on our back. We went through a hell of a process. But during my tenure, BEI became the world’s largest supplier of sensors for automotive stability and rollover prevention.”

In the late Nineties, Madni says, the marketplace for digital stability-control programs exploded, on account of an incident in 1997. An automotive journalist, testing a brand new Mercedes on a check observe, was performing the so-called elchtest, sometimes called the “elk test”: He swerved at regular velocity, meaning to simulate avoiding a moose crossing the highway, and the automobile rolled over. Mercedes and rivals responded to the unhealthy publicity by embracing stability-control programs, and GyroChip demand skyrocketed.

Thanks to the cope with Continental Teves, BEI held a big piece of the automotive market for a few years. BEI wasn’t the one sport on the town at that time—Germany’s Bosch

had begun producing silicon-based MEMS charge sensors in 1998—however the California firm was the one producer utilizing quartz sensors, which on the time carried out higher than silicon. Today, most producers of automotive-grade charge sensors use silicon, for that know-how has matured and such sensors are cheaper to supply.

While manufacturing for the auto market ramped up, Madni continued to search for different markets. He discovered one other huge one within the plane trade.

The Boeing 737 within the early and mid-’90s had been concerned in a

sequence of crashes and incidents that stemmed from surprising rudder motion. Some of the failures have been traced to the plane’s energy management unit, which included yaw-damping know-how. While the yaw sensors weren’t particularly implicated, the corporate did want to revamp its PCUs. Madni and BEI satisfied Boeing to make use of BEI’s quartz sensors in all of its 737s going ahead, in addition to retrofitting current plane with the units. Manufacturers of plane for personal aviation quickly embraced the sensor as properly. And finally the protection enterprise got here again.

Today, digital angular-rate sensors are in nearly each car—land, air, or sea. And Madni’s effort to miniaturize them and scale back their price blazed the path.

By 2005, BEI’s portfolio of applied sciences had made it a pretty goal for acquisition. Besides the speed sensors, it had earned approval for its improvement of the unprecedentedly correct pointing system created for the

Hubble Space Telescope. The sensors and management group had expanded into BEI Sensors & Systems Co., of which Madni was CEO and CTO.

“We weren’t looking for a buyer; we were progressing extremely well and looking to still grow. But several people wanted to buy us, and one, Schneider Electric, was relentless. They wouldn’t give up, and we had to present the deal to the board.”

The sale went via in mid-2005 and, after a quick transition interval and turning down a management place with

Schneider Electric, Madni formally retired in 2006.

While Madni says he’s been retired since 2006, he really retired solely from trade, crossing over right into a busy life in academia. He has served as an honorary professor at six universities, together with the Technical University of Crete, the University of Texas at San Antonio, and the University of Waikato, in New Zealand. In 2011, he joined the college of UCLA’s electrical and computer-engineering division as a distinguished scientist and distinguished adjunct professor and considers that his residence establishment. He is on campus weekly to satisfy along with his advisees, who’re working in sensing, sign processing, AI for sensor design, and ultrawideband high-speed instrumentation. Madni has suggested 25 graduate college students so far.

One of his former UCLA college students, Cejo Ok. Lonappan, now principal programs engineer at

SILC Technologies, says Madni cares so much in regards to the impression of what his advisees are doing, asking them to put in writing an govt abstract of each analysis mission that goes past the know-how to speak in regards to the greater image.

“Many times in academic research, it is easy to get lost in details, in minor things that seem impressive to the person doing the research,” Lonappan says. But Madni “cares a lot about the impact of what we are doing beyond the engineering and scientific community—the applications, the new frontiers it opens.”

S.Ok. Ramesh, a professor and former dean {of electrical} engineering and laptop science at

California State University, Northridge, has additionally seen Madni the advisor in motion.

“For him,” Ramesh says, “it’s not just about engineering. It’s about engineering the future, showing how to make a difference in people’s lives. And he’s not discouraged by challenges.”

“We had a group of students who wanted to take a headset used in gaming and use it to create a brain-control interface for wheelchair users,” Ramesh says. “We spoke to a neurologist, and he laughed at us, said you couldn’t do that, to monitor brain waves with a headset and instantaneously transfer that to a motion command. But Prof. Madni looked at it as how do we solve the problem, and even if we can’t solve it, along the way we will learn something by trying.”

Says Yannis Phillis, a professor on the

Technical University of Crete: “This man knows a lot about engineering, but he has a wide range of interests. When we met on Crete for the first time, for example, I danced a solo Zeibekiko; it has roots from ancient Greece. He asked me questions left and right about it, why this, why that. He is curious about society, about human behavior, about the environment—and, broadly speaking, the survival of our civilization.”

Madni went into engineering hoping to have an effect on humanity along with his work. He is glad that, in at the very least some methods, he has carried out so.

“The space applications have enhanced the understanding of our universe, and I was fortunate to play a part of that,” he says. “My contributions [to automotive safety] in their own humble way have been responsible for saving millions of lives around the world. And my technologies have played a role in the defense and security of our nation. It’s been the most gratifying career.”

From Your Site Articles

Related Articles Around the Web