[ad_1]

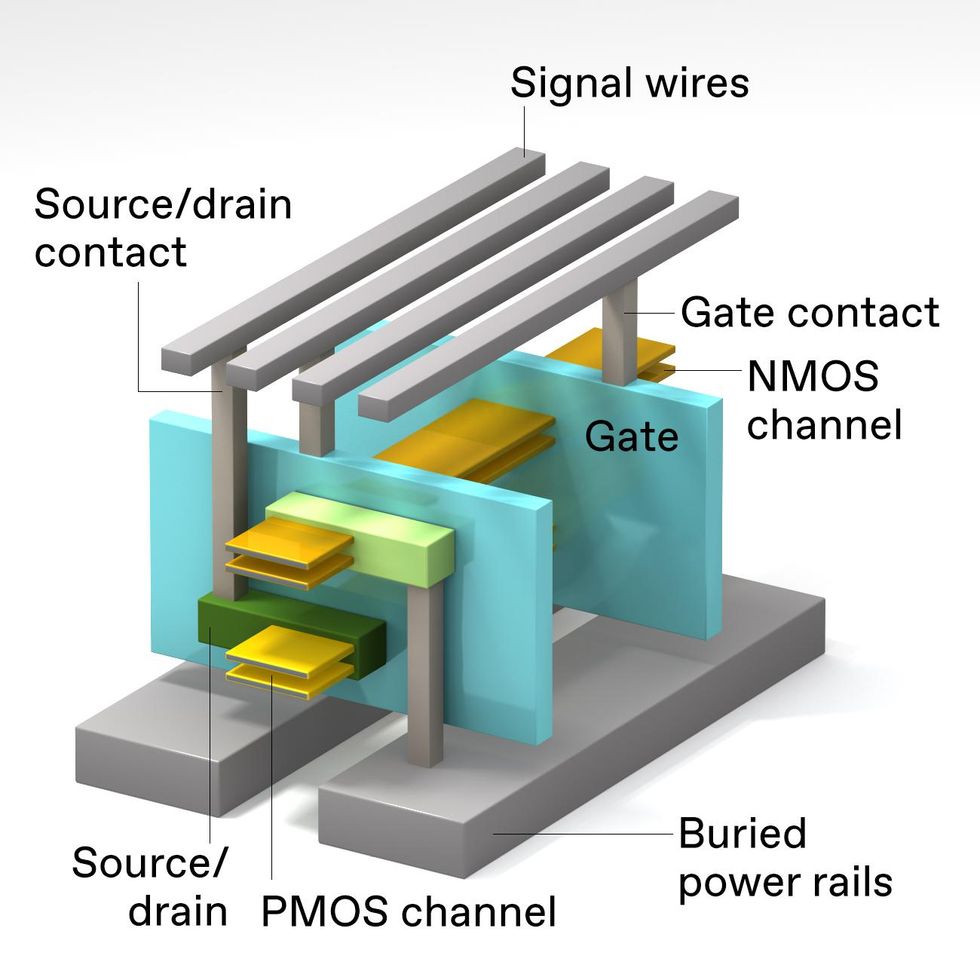

So the place will we flip for future scaling? We will proceed to look to the third dimension. We’ve created experimental gadgets that stack atop one another, delivering logic that’s 30 to 50 p.c smaller. Crucially, the highest and backside gadgets are of the 2 complementary sorts, NMOS and PMOS, which might be the muse of all of the logic circuits of the final a number of a long time. We imagine this 3D-stacked complementary metal-oxide semiconductor (CMOS), or CFET (complementary field-effect transistor), would be the key to extending Moore’s Law into the subsequent decade.

The Evolution of the Transistor

Continuous innovation is a vital underpinning of Moore’s Law, however every enchancment comes with trade-offs. To perceive these trade-offs and the way they’re main us inevitably towards 3D-stacked CMOS, you want a little bit of background on transistor operation.

Every metal-oxide-semiconductor field-effect transistor, or MOSFET, has the identical set of fundamental elements: the gate stack, the channel area, the supply, and the drain. The supply and drain are chemically doped to make them each both wealthy in cellular electrons (

n-type) or poor in them (p-type). The channel area has the alternative doping to the supply and drain.

In the planar model in use in superior microprocessors as much as 2011, the MOSFET’s gate stack is located simply above the channel area and is designed to venture an electrical area into the channel area. Applying a big sufficient voltage to the gate (relative to the supply) creates a layer of cellular cost carriers within the channel area that permits present to stream between the supply and drain.

As we scaled down the traditional planar transistors, what gadget physicists name short-channel results took heart stage. Basically, the gap between the supply and drain turned so small that present would leak throughout the channel when it wasn’t imagined to, as a result of the gate electrode struggled to deplete the channel of cost carriers. To handle this, the business moved to a completely completely different transistor structure referred to as a

FinFET. It wrapped the gate across the channel on three sides to offer higher electrostatic management.

Intel launched its FinFETs in 2011, on the 22-nanometer node, with the third-generation Core processor, and the gadget structure has been the workhorse of Moore’s Law ever since. With FinFETs, we may function at a decrease voltage and nonetheless have much less leakage, lowering energy consumption by some 50 p.c on the similar efficiency stage because the previous-generation planar structure. FinFETs additionally switched sooner, boosting efficiency by 37 p.c. And as a result of conduction happens on each vertical sides of the “fin,” the gadget can drive extra present by means of a given space of silicon than can a planar gadget, which solely conducts alongside one floor.

However, we did lose one thing in shifting to FinFETs. In planar gadgets, the width of a transistor was outlined by lithography, and due to this fact it’s a extremely versatile parameter. But in FinFETs, the transistor width comes within the type of discrete increments—including one fin at a time–a attribute also known as fin quantization. As versatile because the FinFET could also be, fin quantization stays a big design constraint. The design guidelines round it and the will so as to add extra fins to spice up efficiency enhance the general space of logic cells and complicate the stack of interconnects that flip particular person transistors into full logic circuits. It additionally will increase the transistor’s capacitance, thereby sapping a few of its switching pace. So, whereas the FinFET has served us properly because the business’s workhorse, a brand new, extra refined strategy is required. And it’s that strategy that led us to the 3D transistors we’re introducing quickly.

In the RibbonFET, the gate wraps across the transistor channel area to reinforce management of cost carriers. The new construction additionally permits higher efficiency and extra refined optimization. Emily Cooper

In the RibbonFET, the gate wraps across the transistor channel area to reinforce management of cost carriers. The new construction additionally permits higher efficiency and extra refined optimization. Emily Cooper

This advance, the RibbonFET, is our first new transistor structure for the reason that FinFET’s debut 11 years in the past. In it, the gate absolutely surrounds the channel, offering even tighter management of cost carriers inside channels that at the moment are fashioned by nanometer-scale ribbons of silicon. With these nanoribbons (additionally referred to as

nanosheets), we are able to once more fluctuate the width of a transistor as wanted utilizing lithography.

With the quantization constraint eliminated, we are able to produce the appropriately sized width for the appliance. That lets us stability energy, efficiency, and value. What’s extra, with the ribbons stacked and working in parallel, the gadget can drive extra present, boosting efficiency with out rising the realm of the gadget.

We see RibbonFETs as the best choice for greater efficiency at cheap energy, and we will likely be introducing them in 2024 together with different improvements, similar to PowerBy way of, our model of

bottom energy supply, with the Intel 20A fabrication course of.

Stacked CMOS

One commonality of planar, FinFET, and RibbonFET transistors is that all of them use CMOS know-how, which, as talked about, consists of n-type (NMOS) and p-type (PMOS) transistors. CMOS logic turned mainstream within the Eighties as a result of it attracts considerably much less present than do the choice applied sciences, notably NMOS-only circuits. Less present additionally led to higher working frequencies and better transistor densities.

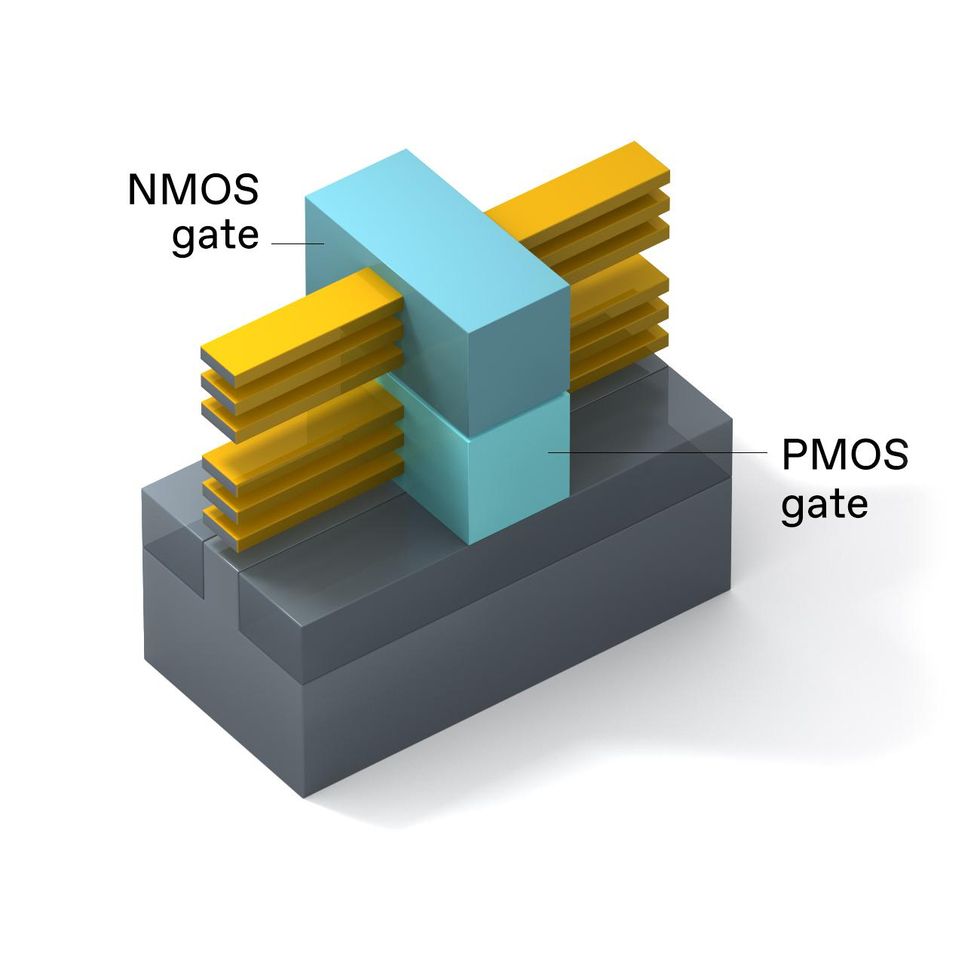

To date, all CMOS applied sciences place the usual NMOS and PMOS transistor pair aspect by aspect. But in a

keynote on the IEEE International Electron Devices Meeting (IEDM) in 2019, we launched the idea of a 3D-stacked transistor that locations the NMOS transistor on high of the PMOS transistor. The following 12 months, at IEDM 2020, we offered the design for the primary logic circuit utilizing this 3D method, an inverter. Combined with applicable interconnects, the 3D-stacked CMOS strategy successfully cuts the inverter footprint in half, doubling the realm density and additional pushing the bounds of Moore’s Law.

3D-stacked CMOS places a PMOS gadget on high of an NMOS gadget in the identical footprint a single RibbonFET would occupy. The NMOS and PMOS gates use completely different metals.Emily Cooper

3D-stacked CMOS places a PMOS gadget on high of an NMOS gadget in the identical footprint a single RibbonFET would occupy. The NMOS and PMOS gates use completely different metals.Emily Cooper

Taking benefit of the potential advantages of 3D stacking means fixing quite a lot of course of integration challenges, a few of which is able to stretch the bounds of CMOS fabrication.

We constructed the 3D-stacked CMOS inverter utilizing what is called a self-aligned course of, through which each transistors are constructed in a single manufacturing step. This means setting up each

n-type and p-type sources and drains by epitaxy—crystal deposition—and including completely different steel gates for the 2 transistors. By combining the source-drain and dual-metal-gate processes, we’re capable of create completely different conductive varieties of silicon nanoribbons (p-type and n-type) to make up the stacked CMOS transistor pairs. It additionally permits us to regulate the gadget’s threshold voltage—the voltage at which a transistor begins to modify—individually for the highest and backside nanoribbons.

How will we do all that? The self-aligned 3D CMOS fabrication begins with a silicon wafer. On this wafer, we deposit repeating layers of silicon and silicon germanium, a construction referred to as a superlattice. We then use lithographic patterning to chop away elements of the superlattice and depart a finlike construction. The superlattice crystal supplies a powerful help construction for what comes later.

Next, we deposit a block of “dummy” polycrystalline silicon atop the a part of the superlattice the place the gadget gates will go, defending them from the subsequent step within the process. That step, referred to as the vertically stacked twin supply/drain course of, grows phosphorous-doped silicon on each ends of the highest nanoribbons (the long run NMOS gadget) whereas additionally selectively rising boron-doped silicon germanium on the underside nanoribbons (the long run PMOS gadget). After this, we deposit dielectric across the sources and drains to electrically isolate them from each other. The latter step requires that we then polish the wafer all the way down to excellent flatness.

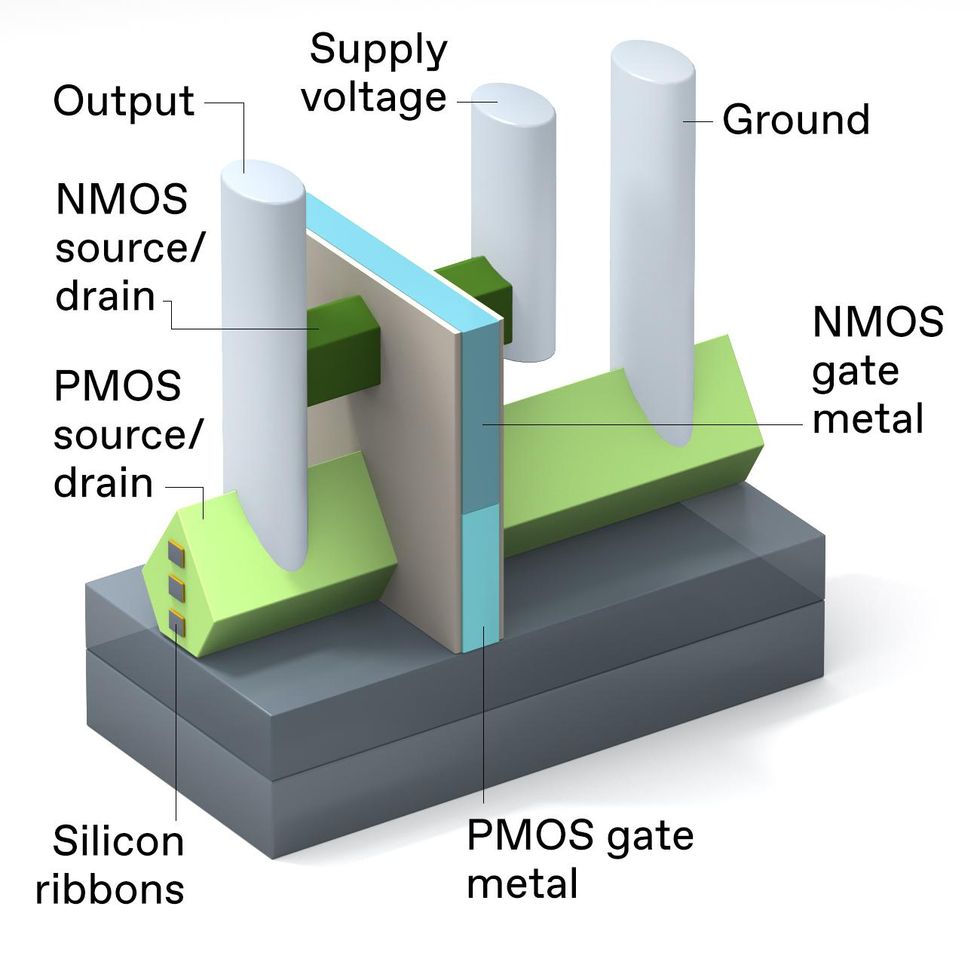

An edge-on view of the 3D stacked inverter exhibits how difficult its connections are. Emily Cooper

An edge-on view of the 3D stacked inverter exhibits how difficult its connections are. Emily Cooper

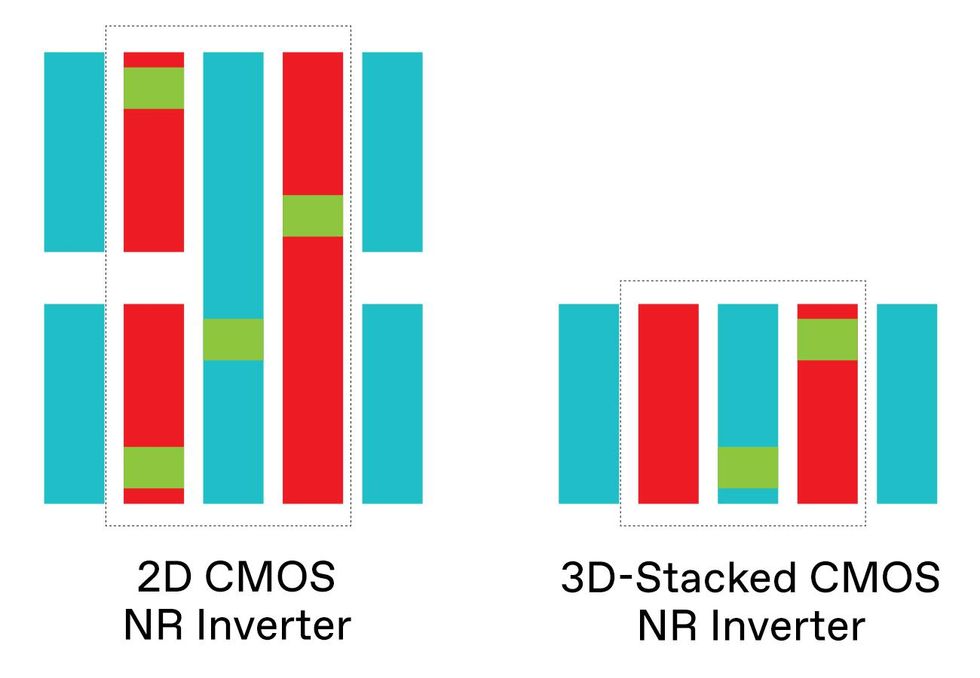

By stacking NMOS on high of PMOS transistors, 3D stacking successfully doubles CMOS transistor density per sq. millimeter, although the true density is determined by the complexity of the logic cell concerned. The inverter cells are proven from above indicating supply and drain interconnects [red], gate interconnects [blue], and vertical connections [green].

By stacking NMOS on high of PMOS transistors, 3D stacking successfully doubles CMOS transistor density per sq. millimeter, although the true density is determined by the complexity of the logic cell concerned. The inverter cells are proven from above indicating supply and drain interconnects [red], gate interconnects [blue], and vertical connections [green].

Finally, we assemble the gate. First, we take away that dummy gate we’d put in place earlier, exposing the silicon nanoribbons. We subsequent etch away solely the silicon germanium, releasing a stack of parallel silicon nanoribbons, which would be the channel areas of the transistors. We then coat the nanoribbons on all sides with a vanishingly skinny layer of an insulator that has a excessive dielectric fixed. The nanoribbon channels are so small and positioned in such a means that we are able to’t successfully dope them chemically as we might with a planar transistor. Instead, we use a property of the steel gates referred to as the work operate to impart the identical impact. We encompass the underside nanoribbons with one steel to make a

p-doped channel and the highest ones with one other to kind an n-doped channel. Thus, the gate stacks are completed off and the 2 transistors are full.

The course of may appear advanced, nevertheless it’s higher than the choice—a know-how referred to as sequential 3D-stacked CMOS. With that methodology, the NMOS gadgets and the PMOS gadgets are constructed on separate wafers, the 2 are bonded, and the PMOS layer is transferred to the NMOS wafer. In comparability, the self-aligned 3D course of takes fewer manufacturing steps and retains a tighter rein on manufacturing value, one thing we demonstrated in analysis and reported at IEDM 2019.

Importantly, the self-aligned methodology additionally circumvents the issue of misalignment that may happen when bonding two wafers. Still, sequential 3D stacking is being explored to facilitate integration of silicon with nonsilicon channel supplies, similar to germanium and III-V semiconductor supplies. These approaches and supplies could change into related as we glance to tightly combine optoelectronics and different features on a single chip.

Making all of the wanted connections to 3D-stacked CMOS is a problem. Power connections will have to be made out of beneath the gadget stack. In this design, the NMOS gadget [top] and PMOS gadget [bottom] have separate supply/drain contacts, however each gadgets have a gate in frequent.Emily Cooper

Making all of the wanted connections to 3D-stacked CMOS is a problem. Power connections will have to be made out of beneath the gadget stack. In this design, the NMOS gadget [top] and PMOS gadget [bottom] have separate supply/drain contacts, however each gadgets have a gate in frequent.Emily Cooper

The new self-aligned CMOS course of, and the 3D-stacked CMOS it creates, work properly and seem to have substantial room for additional miniaturization. At this early stage, that’s extremely encouraging. Devices having a gate size of 75 nm demonstrated each the low leakage that comes with wonderful gadget scalability and a excessive on-state present. Another promising signal: We’ve made wafers the place the smallest distance between two units of stacked gadgets is simply

55 nm. While the gadget efficiency outcomes we achieved will not be information in and of themselves, they do evaluate properly with particular person nonstacked management gadgets constructed on the identical wafer with the identical processing.

In parallel with the method integration and experimental work, we’ve many ongoing theoretical, simulation, and design research underway seeking to present perception into how finest to make use of 3D CMOS. Through these, we’ve discovered among the key concerns within the design of our transistors. Notably, we now know that we have to optimize the vertical spacing between the NMOS and PMOS—if it’s too brief it would enhance parasitic capacitance, and if it’s too lengthy it would enhance the resistance of the interconnects between the 2 gadgets. Either excessive ends in slower circuits that devour extra energy.

Many design research, similar to one by

TEL Research Center America offered at IEDM 2021, give attention to offering all the required interconnects within the 3D CMOS’s restricted house and doing so with out considerably rising the realm of the logic cells they make up. The TEL analysis confirmed that there are numerous alternatives for innovation to find the most effective interconnect choices. That analysis additionally highlights that 3D-stacked CMOS might want to have interconnects each above and beneath the gadgets. This scheme, referred to as buried energy rails, takes the interconnects that present energy to logic cells however don’t carry knowledge and removes them to the silicon beneath the transistors. Intel’s PowerVIA know-how, which does simply that and is scheduled for introduction in 2024, will due to this fact play a key function in making 3D-stacked CMOS a industrial actuality.

The Future of Moore’s Law

With RibbonFETs and 3D CMOS, we’ve a transparent path to increase Moore’s Law past 2024. In a 2005 interview through which he was requested to replicate on what turned his legislation, Gordon Moore admitted to being “periodically amazed at how we’re able to make progress. Several times along the way, I thought we reached the end of the line, things taper off, and our creative engineers come up with ways around them.”

With the transfer to FinFETs, the following optimizations, and now the event of RibbonFETs and ultimately 3D-stacked CMOS, supported by the myriad packaging enhancements round them, we’d wish to assume Mr. Moore will likely be amazed but once more.

From Your Site Articles

Related Articles Around the Web