[ad_1]

This connection of springs is a brand new sort of fabric that may change form and study new properties. Jonathan Hopkins, CC BY-ND

By Ryan H. Lee (PhD Student in Mechanical and Aerospace Engineering, University of California, Los Angeles)

A brand new sort of fabric can study and enhance its capacity to take care of surprising forces due to a novel lattice construction with connections of variable stiffness, as described in a brand new paper by my colleagues and me.

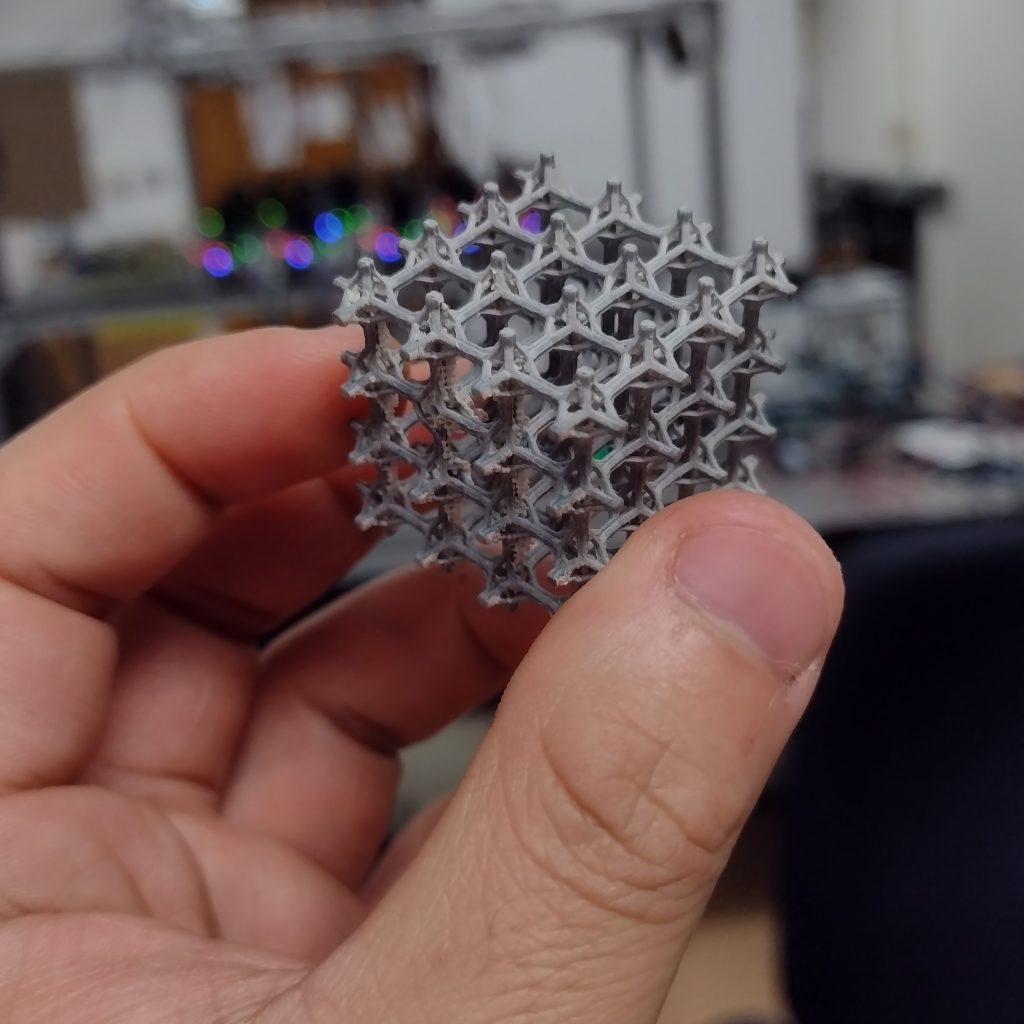

Architected supplies – like this 3D lattice – get their properties not from what they’re made out of, however from their construction. Ryan Lee, CC BY-ND

The new materials is a sort of architected materials, which will get its properties primarily from the geometry and particular traits of its design relatively than what it’s made out of. Take hook-and-loop material closures like Velcro, for instance. It doesn’t matter whether or not it’s constituted of cotton, plastic or some other substance. As lengthy as one facet is a material with stiff hooks and the opposite facet has fluffy loops, the fabric can have the sticky properties of Velcro.

My colleagues and I primarily based our new materials’s structure on that of a man-made neural community – layers of interconnected nodes that may study to do duties by altering how a lot significance, or weight, they place on every connection. We hypothesized {that a} mechanical lattice with bodily nodes may very well be educated to tackle sure mechanical properties by adjusting every connection’s rigidity.

To discover out if a mechanical lattice would have the ability to undertake and preserve new properties – like taking over a brand new form or altering directional energy – we began off by constructing a pc mannequin. We then chosen a desired form for the fabric in addition to enter forces and had a pc algorithm tune the tensions of the connections in order that the enter forces would produce the specified form. We did this coaching on 200 completely different lattice buildings and located {that a} triangular lattice was greatest at reaching all the shapes we examined.

Once the numerous connections are tuned to realize a set of duties, the fabric will proceed to react within the desired means. The coaching is – in a way – remembered within the construction of the fabric itself.

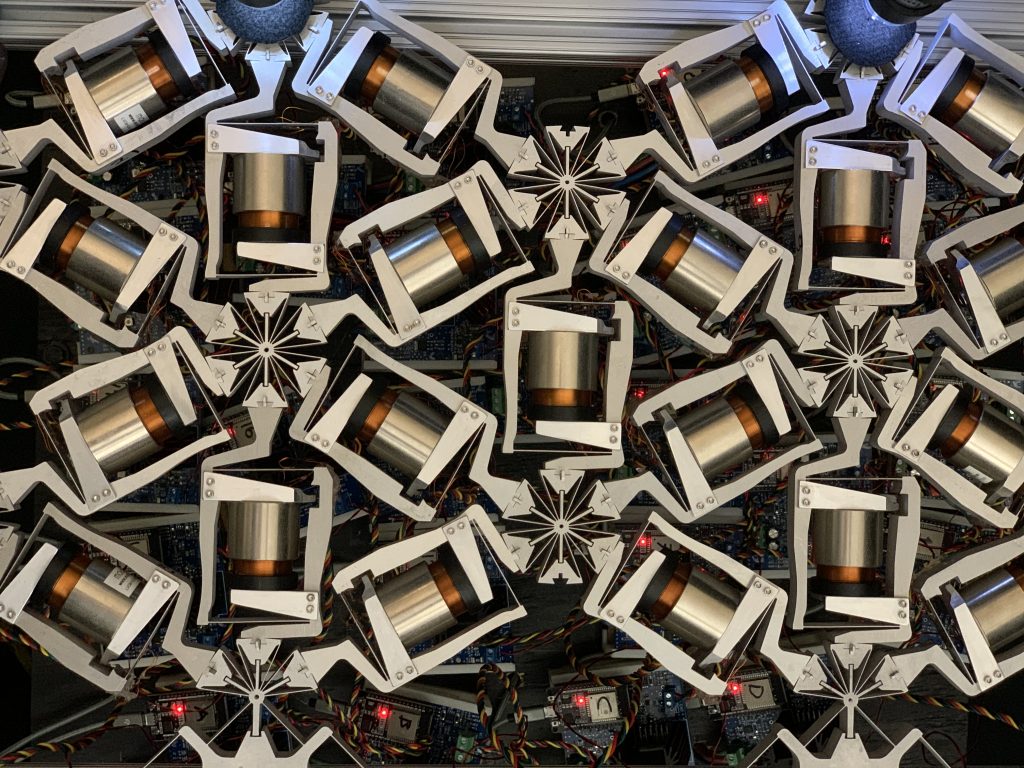

We then constructed a bodily prototype lattice with adjustable electromechanical springs organized in a triangular lattice. The prototype is fabricated from 6-inch connections and is about 2 ft lengthy by 1½ ft broad. And it labored. When the lattice and algorithm labored collectively, the fabric was capable of study and alter form particularly methods when subjected to completely different forces. We name this new materials a mechanical neural community.

The prototype is 2D, however a 3D model of this materials may have many makes use of. Jonathan Hopkins, CC BY-ND

Why it issues

Besides some residing tissues, only a few supplies can study to be higher at coping with unanticipated hundreds. Imagine a airplane wing that immediately catches a gust of wind and is pressured in an unanticipated path. The wing can’t change its design to be stronger in that path.

The prototype lattice materials we designed can adapt to altering or unknown situations. In a wing, for instance, these modifications may very well be the buildup of inner harm, modifications in how the wing is connected to a craft or fluctuating exterior hundreds. Every time a wing made out of a mechanical neural community skilled one in every of these situations, it may strengthen and soften its connections to take care of desired attributes like directional energy. Over time, by way of successive changes made by the algorithm, the wing adopts and maintains new properties, including every habits to the remainder as a kind of muscle reminiscence.

This sort of fabric may have far reaching purposes for the longevity and effectivity of constructed buildings. Not solely may a wing fabricated from a mechanical neural community materials be stronger, it is also educated to morph into shapes that maximize gasoline effectivity in response to altering situations round it.

What’s nonetheless not identified

So far, our group has labored solely with 2D lattices. But utilizing pc modeling, we predict that 3D lattices would have a a lot bigger capability for studying and adaptation. This improve is because of the truth that a 3D construction may have tens of instances extra connections, or springs, that don’t intersect with each other. However, the mechanisms we utilized in our first mannequin are far too advanced to help in a big 3D construction.

What’s subsequent

The materials my colleagues and I created is a proof of idea and exhibits the potential of mechanical neural networks. But to deliver this concept into the true world would require determining how one can make the person items smaller and with exact properties of flex and stress.

We hope new analysis within the manufacturing of supplies on the micron scale, in addition to work on new supplies with adjustable stiffness, will result in advances that make highly effective good mechanical neural networks with micron-scale parts and dense 3D connections a ubiquitous actuality within the close to future.

![]()

Ryan Lee has obtained funding from the Air Force Office of Science Research .

This article appeared in The Conversation.

The Conversation

is an unbiased supply of reports and views, sourced from the educational and analysis neighborhood and delivered direct to the general public.

The Conversation

is an unbiased supply of reports and views, sourced from the educational and analysis neighborhood and delivered direct to the general public.

[ad_2]