[ad_1]

Researchers in South Korea have developed an ultra-small, ultra-thin LiDAR machine that splits a single laser beam into 10,000 factors overlaying an unprecedented 180-degree subject of view. It’s able to 3D depth-mapping a whole hemisphere of imaginative and prescient in a single shot.

Autonomous vehicles and robots want to have the ability to understand the world round them extremely precisely if they’ll be secure and helpful in real-world circumstances. In people, and different autonomous organic entities, this requires a variety of various senses and a few fairly extraordinary real-time knowledge processing, and the identical will possible be true for our technological offspring.

LiDAR – quick for Light Detection and Ranging – has been round for the reason that Nineteen Sixties, and it is now a well-established rangefinding know-how that is significantly helpful in growing 3D point-cloud representations of a given house. It works a bit like sonar, however as an alternative of sound pulses, LiDAR units ship out quick pulses of laser gentle, after which measure the sunshine that is mirrored or backscattered when these pulses hit an object.

The time between the preliminary gentle pulse and the returned pulse, multiplied by the velocity of sunshine and divided by two, tells you the gap between the LiDAR unit and a given level in house. If you measure a bunch of factors repeatedly over time, you get your self a 3D mannequin of that house, with details about distance, form and relative velocity, which can be utilized along with knowledge streams from multi-point cameras, ultrasonic sensors and different programs to flesh out an autonomous system’s understanding of its surroundings.

According to researchers on the Pohang University of Science and Technology (POSTECH) in South Korea, one of many key issues with current LiDAR know-how is its subject of view. If you need to picture a large space from a single level, the one solution to do it’s to mechanically rotate your LiDAR machine, or rotate a mirror to direct the beam. This type of gear might be cumbersome, power-hungry and fragile. It tends to wear down pretty rapidly, and the velocity of rotation limits how usually you’ll be able to measure every level, decreasing the body fee of your 3D knowledge.

Solid state LiDAR programs, alternatively, use no bodily shifting components. Some of them, in keeping with the researchers – just like the depth sensors Apple makes use of to ensure you’re not fooling an iPhone’s face detect unlock system by holding up a flat picture of the proprietor’s face – undertaking an array of dots all collectively, and search for distortion within the dots and the patterns to discern form and distance info. But the sphere of view and backbone are restricted, and the staff says they’re nonetheless comparatively giant units.

The Pohang staff determined to shoot for the tiniest doable depth-sensing system with the widest doable subject of view, utilizing the extraordinary light-bending talents of metasurfaces. These 2-D nanostructures, one thousandth the width of a human hair, can successfully be seen as ultra-flat lenses, constructed from arrays of tiny and exactly formed particular person nanopillar components. Incoming gentle is break up into a number of instructions because it strikes by a metasurface, and with the proper nanopillar array design, parts of that gentle might be diffracted to an angle of almost 90 levels. A totally flat ultra-fisheye, should you like.

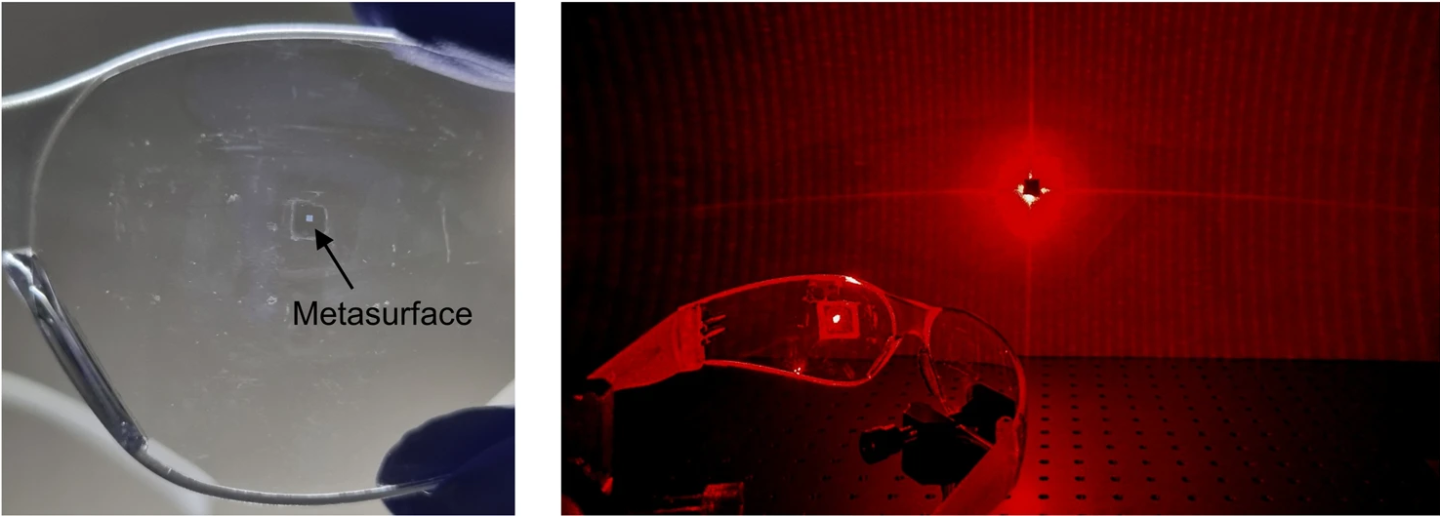

POSTECH

The researchers designed and constructed a tool that shoots laser gentle by a metasurface lens with nanopillars tuned to separate it into round 10,000 dots, overlaying an excessive 180-degree subject of view. The machine then interprets the mirrored or backscattered gentle through a digital camera to supply distance measurements.

“We have proved that we will management the propagation of sunshine in all angles by growing a know-how extra superior than the traditional metasurface units,” mentioned Professor Junsuk Rho, co-author of a brand new research printed in Nature Communications. “This will probably be an unique know-how that can allow an ultra-small and full-space 3D imaging sensor platform.”

The gentle depth does drop off as diffraction angles develop into extra excessive; a dot bent to a 10-degree angle reached its goal at 4 to seven instances the facility of 1 bent out nearer to 90 levels. With the tools of their lab setup, the researchers discovered they acquired greatest outcomes inside a most viewing angle of 60° (representing a 120° subject of view) and a distance lower than 1 m (3.3 ft) between the sensor and the item. They say higher-powered lasers and extra exactly tuned metasurfaces will enhance the candy spot of those sensors, however excessive decision at higher distances will all the time be a problem with ultra-wide lenses like these.

POSTECH

Another potential limitation right here is picture processing. The “coherent level drift” algorithm used to decode the sensor knowledge right into a 3D level cloud is extremely advanced, and processing time rises with the purpose depend. So high-resolution full-frame captures decoding 10,000 factors or extra will place a reasonably powerful load on processors, and getting such a system working upwards of 30 frames per second will probably be an enormous problem.

On the opposite hand, this stuff are extremely tiny, and metasurfaces might be simply and cheaply manufactured at monumental scale. The staff printed one onto the curved floor of a set of security glasses. It’s so small you’d barely distinguish it from a speck of mud. And that is the potential right here; metasurface-based depth mapping units might be extremely tiny and simply built-in into the design of a variety of objects, with their subject of view tuned to an angle that is sensible for the appliance.

The staff sees these units as having big potential in issues like cellular units, robotics, autonomous vehicles, and issues like VR/AR glasses. Very neat stuff!

The analysis is open entry within the journal Nature Communications.

Source: POSTECH