[ad_1]

News briefs for the week check out cobots and robots getting their very own model of GenAI, a brand new retail robotic within the magnificence enterprise portray fingernails in 10 minutes for $10, an automatic rail observe restore system for European railroads, a subsea robotic and automatic floor car that work collectively as a staff, and an automatic navigation system for any industrial car from farm tractor to bulldozer.

Cobots fitted with RoboGPT

San Francisco-based Orangewood Labs desires to construct “a cheap, programmable robotic arm for manufacturing.”

“Robotic arms have been traditionally hard to program, which is why most small businesses don’t do it,” says Orangewood. “Any  change in the environment or conditions requires reprogramming. For example, if you wanted to pick a red triangle instead of a blue square, it’d take time to make that change. We’re changing that with RoboGPT.”

change in the environment or conditions requires reprogramming. For example, if you wanted to pick a red triangle instead of a blue square, it’d take time to make that change. We’re changing that with RoboGPT.”

RoboGPT, as its identify implies, is ChatGPT for robots and cobots. Type in a immediate like, “Pick up all the cylinders with blue tops and place them into the red container.” Then after hitting Enter, the cobot complies in doing precisely what was requested of it.

RoboGPT is a platform that permits customers — suppose roboticists in addition to manufacturing unit flooring employees — to program Orangewood’s robotic arm with textual content or their voice. RoboGPT, engineered to be adaptive, makes an attempt to account for edge instances, repeatedly studying from and about its atmosphere.

With the launch of RoboGPT, Orangewood hopes to take its robotics into use instances, like high quality inspection, powder coating, and choosing and sorting packaged items.

As it claims on the corporate web site: “Orangewood builds AI-powered robotic arms that are simple to operate. We make collaborative robots safe, affordable, and capable of coping with modern-day manufacturing challenges.”

Robot’s excellent nail portray for $10

“Manicures in minutes” says the robotic’s developer Clockwork, but it’s actually solely nail portray, however most likely the quickest and most correct nail coating you’ll ever have. “10 minutes for $10,” the advert informs.

Clockwork CEO Renuka Apte says that demand for the machine is ‘very strong’ and requests for the robotic are coming from everywhere in the  world. Although already in six choose Target shops, Clockwork simply debuted certainly one of its fully-autonomous nail portray robots in Beverly Hills.

world. Although already in six choose Target shops, Clockwork simply debuted certainly one of its fully-autonomous nail portray robots in Beverly Hills.

Clockwork makes use of AI and 3D know-how to successfully paint nails in beneath 10 minutes for about $10, giving clients a fast polish change. Customers can bask in quite a lot of colours from manufacturers akin to Essie, OPI, and Zoya.

According to Boston Consulting Group, all skilled companies robots, together with manicure bots, will see exponential development within the coming years, reaching $170 billion by 2030.

Apte explains that the Clockwork MiNiCURE, as she calls it, is so exact as a result of the robotic takes an image of every finger with its twin 3D cameras, stitches them collectively, and ships the end result to its proprietary AI.

“Our AI can establish edges inside 0.3mm accuracy and tells the robotic what’s pores and skin and what’s nail. This is then despatched to our refined algorithms which decide how the nozzle ought to transfer to deposit nail polish in the precise locations.”

As one glad buyer added, I can sit in silence and watch my nails being carried out as a substitute of tolerating a small-talk barrage from the manicurist.

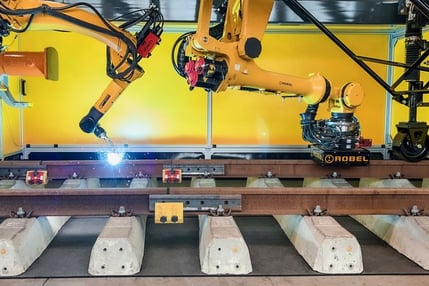

Robot rail repairing in European Union

The Robel/FANUC automated rail observe restore system is on the job within the European Union (EU), and its arrival is well timed.

The Robel/FANUC automated rail observe restore system is on the job within the European Union (EU), and its arrival is well timed.

The EU, reasoning that the restore of highways is rather more expensive than rail strains, desires to shift freight shipments from vans to trains. European Railway Infrastructure: A Review (2018) is asking for “the goal of transferring as much as 30% of the freight traveled by distances exceeding 300 km for different modes of transport, akin to rail or water, by 2030 and greater than 50% by the 12 months 2050.

Even although the EU declared 2021 the ‘Year of Rail’, Europe’s 216,000 km community of energetic railways, in response to one report titled Derailed — The Desolate State of European Railways, is badly in want of restore.

Ralf Völlinger, GM Robotics at FANUC Europe, provides that he’s optimistic in regards to the future use of robots for infrastructure upkeep: “There is plenty of want for modernization in each the rail and highway networks. Robots may help to finish prolonged upkeep initiatives extra rapidly by taking on repetitive work and thus not less than partially compensate for the rising labor scarcity.”

The automated rail observe restore system is a collaboration between Robel Automation and Japan’s FANUC. Robel Rail Automation from Bavaria, Germany, designed and manufactured the system, leveraging FANUC’s industrial robots to be central to the undertaking.

The automated rail observe restore system is a collaboration between Robel Automation and Japan’s FANUC. Robel Rail Automation from Bavaria, Germany, designed and manufactured the system, leveraging FANUC’s industrial robots to be central to the undertaking.

“We are seeing excessive demand from our clients for absolutely automated, robot-assisted upkeep methods,” says Thomas Weis, head of growth at Robel Rail Automation. This is particularly true for the time-consuming and sophisticated restore work. Here, rail community operators are more and more missing expert employees akin to welders.

In phrases of configuration, the system incorporates a rail-traversing wagon mounted by two FANUC robots. The robots detect inner and exterior defects and carry out absolutely computerized repairs utilizing welding, milling, and grinding processes.

With prototypes in operation at the moment, full business availability is anticipated in two to a few years.

Fleets of subsea robots proposed

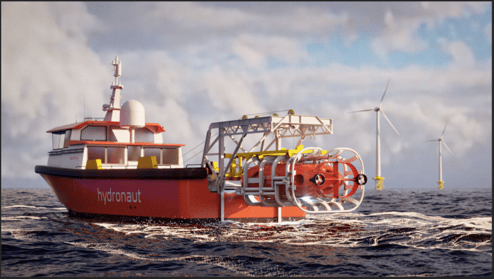

Nicolaus Radford, CEO of Houston-based Nauticus Robotics envisions a fleet of his subsea robots (Aquanauts), every tended by a fleet of floor ships (Hydronauts), working as a staff with each subsea and floor vessels completely autonomous.

“My dream,” he enthuses, “is to have a network of Aquanauts and Hydronauts out there working, a whole navy of them, being controlled by control centers around the world, out there 24/7 doing their thing. That’s the core of the business. There’s an ocean of opportunity to take advantage of from fisheries to countering global security threats, which have been heightened recently, with increased underwater surveillance to protect critical infrastructure, such as pipelines and communications cables.”

“My dream,” he enthuses, “is to have a network of Aquanauts and Hydronauts out there working, a whole navy of them, being controlled by control centers around the world, out there 24/7 doing their thing. That’s the core of the business. There’s an ocean of opportunity to take advantage of from fisheries to countering global security threats, which have been heightened recently, with increased underwater surveillance to protect critical infrastructure, such as pipelines and communications cables.”

The firm’s 59-foot autonomous floor vessel (ASV) Hydronaut, is particularly designed to move, deploy, talk with, recharge, and get well Aquanaut, the corporate’s subsea robotic (see photographs)

The Aquanaut (MK2) is a totally electrical, untethered, and autonomous “subsea robot that is controlled through acoustic communication networking. The artificial intelligence-based software suite allows for robotic controls, user interfaces, sensor integration, simulation, data analysis, and communication frameworks purpose-built to enable subsea work.”

In its intervention mode, the MK2 “utilizes two of Nauticus’ Olympic Arms – electric work-class manipulators – to interact with subsea infrastructure and objects to complete complex underwater tasks.”

Polymath autonomous navigation

Got an industrial car that you just’d wish to automate? Anyone will do from farm tractor to construction-site bulldozer. San Francisco-based Polymath Robotics claims on its web site: “Effortlessly add autonomous navigation to any industrial vehicle, so you can focus on  what makes your customers tick.”

what makes your customers tick.”

Founded in 2021, Polymath develops autonomous car software program for industrial autos. Any sort of industrial car, which incorporates an infinite vary of car sizes and functionalities.

According to TechCrunch, “Stefan Seltz-Axmacher, co-founder Ilia Baranov and their new startup Polymath Robotics, have developed a plug-and-play software platform and an accompanying SDK that allows companies to quickly and cost efficiently automate industrial vehicles. Think of it as SaaS for industrial robotics.”

The startup is constructing fundamental generalizable autonomy designed to automate the 50 million or so industrial autos which are working in closed environments at the moment (which means not on the open highway or public methods). In simulation, the software program platform lets a warehouse proprietor, farmer or mining firm skip the same old lengthy time period to construct out autonomy, after which rapidly apply it to a real-world car (see video).

![]()

[ad_2]