[ad_1]

News briefs for the week check out the revolution in new-age logistics, the place many technical duties are rapidly diminishing whereas others are arriving simply as rapidly; like the mix of AR, VR, 5G, and superior imaging to industries interacting with simulation, predictive upkeep, constructing administration, distant operation, and superior robotics…all in unison! We additionally check out three builders and their new-age solutions to the old-world difficulties of transferring pallets.

The revolution in new-age logistics

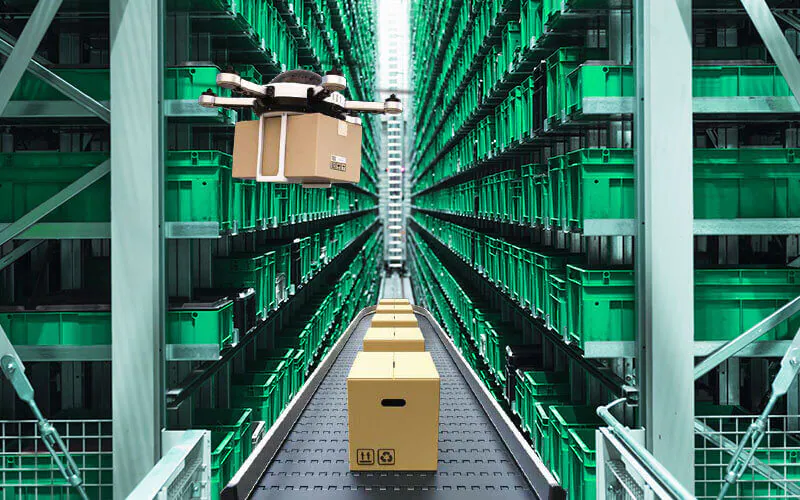

In the previous few years, 5 issues have been taking place in robot-driven automation of logistics which might be laborious NOT to note: 1. Robots  and cobots taking over much less house; 2. extra inexpensive; 3. sooner packaging; 4. improved office security; and, 5. time freed up for workers to do different value-added duties (or to be laid off).

and cobots taking over much less house; 2. extra inexpensive; 3. sooner packaging; 4. improved office security; and, 5. time freed up for workers to do different value-added duties (or to be laid off).

That’s the take of Brad Arrington chief editor of Packaging Strategies and Flexible Packaging in his article titled Technology is Revolutionizing Cartoning and Case Packing.

The checklist of the the reason why the 5 issues are taking place in logistics is there should you dig it out. Arrington’s digging uncovered issues like enhancements in “machine vision, end-of-arm tooling technology, artificial intelligence (AI), machine learning, durability, and safety.”

In addition, robots and cobots have grow to be easier to each program and function, decreasing the extent of technical talent wanted for profitable deployment. However, what’s altering for workers is that they should purchase new expertise for predictive analytics pushed by synthetic intelligence, machine studying, and edge computing.

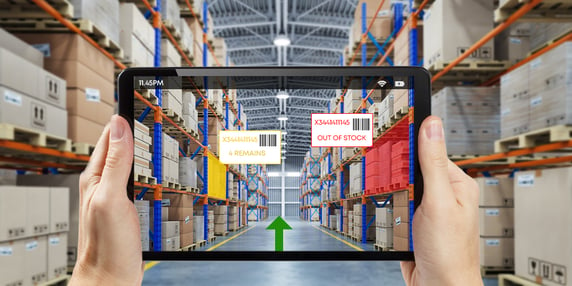

The use of AR (augmented actuality) and VR (digital actuality) applied sciences (with 5G mobile) in industrial purposes can also be rising considerably, serving to producers, logistic operators, and different organizations to enhance productiveness, scale back prices, and be extra environment friendly and aggressive.

So, as staff see expertise for working robots and cobots diminishing, new expertise come up and are being required for combining AR, VR, and superior imaging for industries to work together with totally different property and employees utilizing digital twins. Today, digital twin purposes embrace simulation, predictive upkeep, constructing administration, distant operation, and superior robotics.

So, as staff see expertise for working robots and cobots diminishing, new expertise come up and are being required for combining AR, VR, and superior imaging for industries to work together with totally different property and employees utilizing digital twins. Today, digital twin purposes embrace simulation, predictive upkeep, constructing administration, distant operation, and superior robotics.

Professor Karthik Ramani of Purdue University works with producers to create digital factories. They can discover labor-saving applied sciences utilizing AR earlier than implementing them in a manufacturing unit or warehouse settings. “AR lets users see exactly where a robot will move just by looking at their surrounding environment,” says Ramani. “There is no need to translate a location from a map overlay to the real-world environment, which might incur an additional cognitive burden, as that work has already been done for them.”

All of those new expertise assist manufacturing unit and warehouse employees to work together with robots and cobots. In flip, they’ll decide if the robotic can assist enhance productiveness. They also can just about experiment with flooring preparations to maximise productiveness.

Addington factors to Peregrine for example of “a high-speed, vision-guided, robotic, top-load cartoning system. With a small footprint one-third the size of traditional top- and end-load cartoners, Peregrine places carton forming, loading, and closing inline so there’s no wasted real estate, saving food producers valuable floor space.”

In trade for elevated productiveness and robots which might be simpler to program, deploy and function, new skillsets for workers will make the most of AR, robots, and cobots with imaginative and prescient as among the many key improvements taking effectivity to the following stage.

New movers for outdated pallets

The venerable transport pallet hasn’t modified its seems to be a lot in over seventy years. However, as soon as loaded and in want of being moved, all method of latest machines are prepared to maneuver pallets sooner, cheaper, and extra productively than ever.

Formerly, with solely pallet jacks as assistive gadgets, pallets have been sluggish movers, typically taking an hour or extra to unload a trailer. Over the years, the dock has grow to be a focus for warehouse automation, and wonderful robotics have been constructed to mitigate a few of the bottlenecks.

Three new entries made an look on the not too long ago concluded ProMat 2023 in Chicago.

Big Joe’s Pallet Mover

With a historical past of seventy years of supplies dealing with, Big Joe Lift Trunks (now majority owned by China’s EP Equipment), is out with its newly developed autonomous Big Joe’s Pallet Mover, a brand new—both user-directed or absolutely autonomous—cellular robotic.

As with many logistics robots developed previously few years, there appears at all times to be an AI element crucial for the construct. For the Pallet Move, it was Thoro.ai and its self-driving expertise.

As with many logistics robots developed previously few years, there appears at all times to be an AI element crucial for the construct. For the Pallet Move, it was Thoro.ai and its self-driving expertise.

Developed in partnership with Thoro.ai, the Big Joe Pallet Mover is an easy-to-deploy autonomous answer for floor-to-floor pallet transportation and drop-off.

Essentially, Pallet Mover is an automatic pallet jack with self-driving capabilities. The consumer, from the intuitive pill interface, instructs the Pallet Mover the place to go. And off it goes! “Pallet Mover can transport up to 4,400 lbs. of materials at speeds of up to 2.8 mph and can operate continuously for up to 10 hours.”

“The magic to that is our user-directed approach to automation,” stated Bill Pedriana, Big Joe’s chief advertising officer, “which, by nature, is focused on empowering workers and eliminating the need for complicated systems integration.”

The new Big Joe Pallet Mover works identical to a traditional raise truck however options LiDAR, and a digicam system to move and drop pallets to places autonomously as soon as the operator masses it and selects a mission.

The self-driving expertise element for Big Joe’s is likened to a “productivity force multiplier” that enables employees to give attention to higher-value duties.

ForwardX Robotics’s Apex C1500-L

Forklift for all seasons? The new, ForwardX Apex C1500-L autonomous forklift was designed with a number of workflows in thoughts, together with receiving, inventory put away, restocking, cross-zone dealing with, conveyor docking, and outbound workflow.

Forklift for all seasons? The new, ForwardX Apex C1500-L autonomous forklift was designed with a number of workflows in thoughts, together with receiving, inventory put away, restocking, cross-zone dealing with, conveyor docking, and outbound workflow.

Flexibility, and larger autonomy, are the hallmarks of this new providing, which was additionally on show at ProMat2023.

Nicolas Chee CEO of ForwardX Robotics, says that the brand new Apex C1500-L fills a much-needed place within the firm’s product lineup as a result of it has a payload capability of three,300 lbs., and ensures ±2.3 in pallet placement precision. “The forklift can identify the angle at which a pallet is placed and adjust autonomously in real-time to complete its task even when a pallet is misplaced.”

Seegrid

Seegrid introduced its well-known Palion AMRs to ProMat2023; it’s a fleet, in keeping with Seegrid, that has “driven nearly 10 million autonomous miles in customer production environments.”

For ProMat, Seegrid had some expanded capabilities constructed into the Palion Lift and Palion Tow Tractor: Lift and Tow Tractor can now “work in combination to load and unload carts with no human intervention necessary,” which beforehand had been a troublesome, time-consuming and labor-intensive workflow