[ad_1]

News briefs for the week check out cobot options for decide n’ pack style attire SKUs, exosuit to handle spastic muscle situations, selfmade ingenuity in service robots, a 3D-printed cobot arm that truly “works”, and the 45-second, robot-made pizza in a transferring truck.

Cobot resolution: decide n’ pack style SKUs

If you’re a cobot vendor and don’t but have an answer for choosing and packing attire/style SKUs, you then’re lacking out on a huge, international B2C eCommerce market section, which is estimated at $752.5 billion (2020), and forecast for 2025 to be $1.1 trillion.

Apparel and style don’t ship on hangers. Most typically attire and style objects are these SKUs that come to a packing space in shiny plastic packaging that’s extremely reflective and tough for imaginative and prescient techniques to see; and due to this fact, tough to acknowledge and kind…and, for that matter, to type shortly and productively (like 700 SKUs an hour). The similar shiny packaging may additionally current difficulties for a cobot’s gripper to correctly decide up and kind.

Therefore, a specifically tailor-made resolution to the attire/style problem is extremely fascinating. And Netherlands-based Smart Robotics (based 2015), which is most positively within the decide and pack cobot biz, has simply introduced theirs: the Smart Fashion Picker. How applicable.

Therefore, a specifically tailor-made resolution to the attire/style problem is extremely fascinating. And Netherlands-based Smart Robotics (based 2015), which is most positively within the decide and pack cobot biz, has simply introduced theirs: the Smart Fashion Picker. How applicable.

Smart Robotics’ PR launch claims that its Smart Fashion Picker “can pick a large variety of fashion items, which are placed in protective wrapping [the aforementioned [“shiny packaging”], straight from a cart or bin. Vision sensors, movement and process planning algorithms assist the cobot to calculate what to choose subsequent, in addition to find out how to decide and place the merchandise precisely into the following bin, and it will probably simply detect when the bin is empty or stuffed.”

Smart Robotics says the Smart Fashion Picker is “one of the many improvements it has in the pipeline to make warehouse automation more versatile and dynamic in a highly performant logistics industry”.

“We’re super excited to introduce this product to the wider market after successful implementation with our initial customers,” says Johan Jardenvall, CEO at Smart Robotics.

Of course, solely time will inform how efficient the Smart Fashion Picker is on the job, however, for now, the seller is presenting the specified tailor-made Pick N’ Pack system on the precise proper time throughout a development spurt within the trade.

When exoskeletons turn into garments: the exosuit

Those that suffer from a number of sclerosis (MS), cerebral palsy (CP) or stroke don’t see an exoskeleton or exosuit, slightly, they see a godsend!

Invented in 2009 by Swedish chiropractor, Fredrik Lundqvist, the Exopulse Mollii Suit’s full-body exosuite, with 58 embedded electrodes, fireplace 20 instances per second utilizing focused electrical impulses so as to right mobility issues. The exosuit is thought formally as a drug-free, non-invasive spasticity administration system with modern, near-full-body neuro-stimulation. To Lundqvist, it’s a wearable robotic.

Invented in 2009 by Swedish chiropractor, Fredrik Lundqvist, the Exopulse Mollii Suit’s full-body exosuite, with 58 embedded electrodes, fireplace 20 instances per second utilizing focused electrical impulses so as to right mobility issues. The exosuit is thought formally as a drug-free, non-invasive spasticity administration system with modern, near-full-body neuro-stimulation. To Lundqvist, it’s a wearable robotic.

In 2021, German med-tech big Ottobock acquired Lundqvist’s Exoneural Network, shopping for 100% of the excellent shares. Together with its earlier acquisition of US-based SuitX (occupational exoskeletons), Ottobock is now the worldwide chief of prosthetics, orthotics, and exoskeletons.

Lundqvist’s exosuit, nonetheless manufactured in Sweden, is available in 37 completely different sizes ranging from 2–3 years of age and as much as 5XL for women and men. Cost: $5800 or $540 rental per 30 days.

Better nonetheless, a lifetime sentence of involuntary and steady muscle spasms is 100% corrected by a wearable robotic (see video).

In reward of selfmade robots

COVID has prompted the spending worldwide of some $228 billion for purchases of endpoint units, robotics, and drones…simply in 2021 alone! But it doesn’t take billions of {dollars}, as a small city in Indonesia has proven, to create service robots that disinfect and tote meals and provides to these in lockdown. Ingenuity and localized innovation can go a great distance.

With a robotic’s head produced from an previous rice cooker, chest from a discarded tv set, and its base from a junked toy automotive chassis, the residents of the Tembok Gede district of Surabaya, capital of the Indonesian province of East Java, are making due by mainly dumpster-diving and improvising robotics gear.

With a robotic’s head produced from an previous rice cooker, chest from a discarded tv set, and its base from a junked toy automotive chassis, the residents of the Tembok Gede district of Surabaya, capital of the Indonesian province of East Java, are making due by mainly dumpster-diving and improvising robotics gear.

Particularly arduous hit with COVID, particularly the Delta variant (Indonesia has had 3.68 million COVID infections and greater than 108,000 deaths), the villagers of Tembok Gede, below the route of some native engineering professors, constructed a service robotic they named Delta.

Aseyanto (makes use of just one title), a neighborhood chief who heads the “Delta robot” challenge, stated: “With this new Delta variant and the surging variety of COVID-19 circumstances, I made a decision to show the robotic into one used for public providers resembling to spray disinfectant, ship meals and meet the wants of residents who’re self-isolating.”

After transferring down the road to the house of a self-isolating villager, the robotic’s speaker sends out the message “Peace be with you,” adopted by “A supply is right here. Get properly quickly.”

Operated by distant management, with twelve hours of battery life, Delta is now considered one of a number of robots made within the village that has received Tembok Gede a popularity for its inventive use of know-how.

3D-printed robotic arm that actually works!

There are many 3D-printed robotic arms obtainable, however most are fantastic academic toys and never reduce out for actual work, like machine tending in a manufacturing facility or piece choosing in e-commerce.

Not so for Real Robot One or RR1 from the laboratory of Pavel Surynek. Sure, it’s a prototype, but it surely’s a primary, and will properly result in a close to way forward for high-grade, 3D-printed robotic and cobot arms turning into common gamers in industrial robotics.

The standards for a helpful robotic or cobot arms are precision, accuracy, repeatability, and power; and the RR1 checks off all these packing containers, which has been a close to impossibility by way of any 3D-printing course of, till now.

The standards for a helpful robotic or cobot arms are precision, accuracy, repeatability, and power; and the RR1 checks off all these packing containers, which has been a close to impossibility by way of any 3D-printing course of, till now.

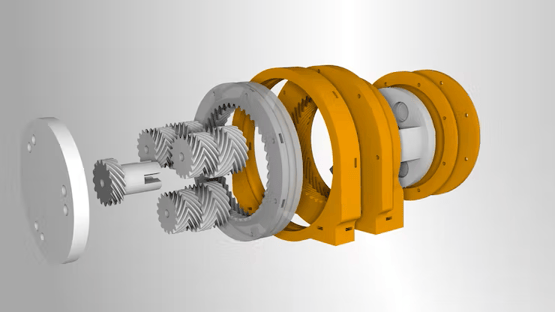

RR1 (Real Robot One),” like most multi-axis robotic and cobot arms, has stepper motors that rotate the joints. However, the RR1 is exclusive in that every motor has a 3D-printed planetary gearbox to extend torque and motor output decision.

“Those help the robotic arm lift quite a bit of weight and move with precision,” says Surynek. The RR1 has six joints, so it incorporates six of these gearboxes. The remaining diploma of freedom is the tip effector, which is a servo-driven gripper.”

In this drawing (see exploded view), the planetary gearbox consists of three planets—herringbone gears—and one center gear related to the motor axle.

Amazingly, Surynek has pulled off the design engineering and manufacturing of this complicated planetary gearbox with a 3D printer, which is a key growth in making robotic and cobot arms really helpful.

Robot’s record-setting, 45-second pizza!

Founded in 2019, by former SpaceX engineer Benson Tsai, (and 23 different former SpaceX staff), however not launching till the autumn of 2022, new robotic startup, LA-based Stellar Pizza, has skilled its robots to knock out an oven-ready, giant pizza in 45 seconds.

That’s record-setting velocity for an autonomous machine, however nonetheless, a slowpoke in comparison with two-time world champion, Canadian Werner Lomker, who made three giant pizzas in a powerful 47.56 seconds—equal to creating every pizza in roughly 15 seconds!

Of course, Stellar Pizza’s robots can work the dough, tomato sauce, and grated mozzarella circuit across the clock with out stopping; Lomker’s productiveness, alternatively, has its limits.

With the worldwide pizza trade price $160 billion in annual gross sales (largest market Western Europe at $60 billion, adopted by North America (U.S. and Canada) with $56 billion), there’s worth in speedy, extremely productive robots.

With the worldwide pizza trade price $160 billion in annual gross sales (largest market Western Europe at $60 billion, adopted by North America (U.S. and Canada) with $56 billion), there’s worth in speedy, extremely productive robots.

According to Tsai, the principle downside that Stellar Pizza solves is the rising meals prices within the United States. The USDA’s inflation watch concluded that discovered there was extra inflation for grocery and grocery store retailer purchases then for eating places.

Stellar Pizza hopes to deal with this downside immediately by promoting on to its goal buyer: individuals who need meals shortly and conveniently. Stellar Pizza has raised $9 million from three VC companies.

“The course of to make them isn’t terribly completely different from that of pizzas made by human arms; first, a metallic arm lowers right into a refrigerated field and grabs a ball of dough, depositing it onto a conveyor belt, the place a disc lowers to press it right into a 12-inch circle (the corporate makes the dough at its headquarters then masses it into the machine’s fridge in pre-portioned balls).

“As the raw crust moves along on the belt, various machines dot it with tomato sauce, shake cheese onto it, add other toppings, then lift it into a 900-degree oven for baking. The pie’s journey is tracked by cameras and sensors, which can make adjustments as needed.”

Each 12-inch, 45-second pizza, relying on topping selections, prices $7 to $10.

BTW: All of this takes place in a transferring truck!

![]()