[ad_1]

This sponsored article is dropped at you by COMSOL.

“Laws, Whitehouse received five minutes signal. Coil signals too weak to relay. Try drive slow and regular. I have put intermediate pulley. Reply by coils.”

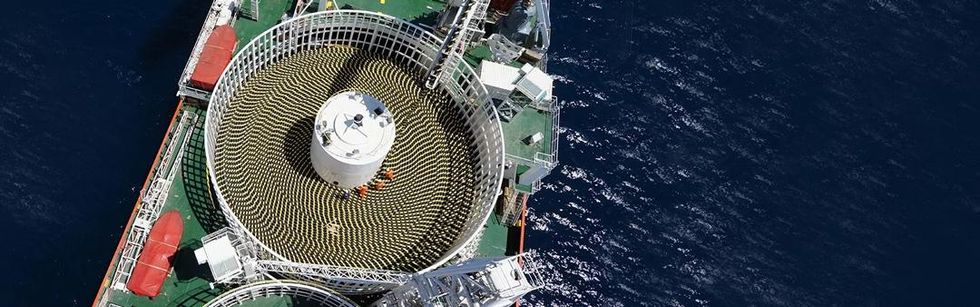

Sound acquainted? The message above was despatched by means of the primary transatlantic telegraph cable between Newfoundland and Ireland, method again in 1858. (“Whitehouse” refers back to the chief electrician of the Atlantic Telegraph Company on the time, Wildman Whitehouse.) Fast ahead to 2014: The backside of the ocean is house to almost 300 communications cables, connecting international locations and offering web communications world wide. Fast ahead once more: As of 2021, there are an estimated 1.3 million km of submarine cables (Figure 1) in service, starting from a brief 131 km cable between Ireland and the U.Okay. to the 20,000 km cable that connects Asia with North America and South America. We know what the world of submarine cables appears like immediately, however what in regards to the future?

Figure 1. Submarine cables hold the world linked.

Moving Wind Power Offshore

The offshore wind (OFW) business is among the most quickly advancing sources of energy world wide. It is smart: Wind is stronger and extra constant over the open ocean than it’s on land. Some wind farms are able to powering 500,000 houses or extra. Currently, Europe leads the market, making up nearly 80 p.c of OFW capability. However, the worldwide demand for power is predicted to extend by 20 p.c in 10 years, with a big majority of that demand provided by sustainable power sources like wind energy.

Offshore wind farms (Figure 2) are made up of networks of generators. These networks embrace cables that join wind farms to the shore and provide electrical energy to our energy grid infrastructure (Figure 3). Many OFW farms are made up of grounded constructions, like monopiles and different varieties of bottom-fixed wind generators. The foundations for these constructions are costly to assemble and tough to put in in deep sea environments, because the cables must be buried within the seafloor. Installation and upkeep is less complicated to perform in shallow waters.

Wind generators for offshore wind farms are beginning to be constructed additional out into the ocean. This creates a brand new want for well-designed subsea cables that may attain longer distances, survive in deeper waters, and higher join our world with sustainable energy.

The way forward for offshore wind lies in wind farms that float on ballasts and moorings, with the cables laid instantly on the seafloor. Floating wind farms are a fantastic answer when wind farms located simply off the coast develop crowded. They may also reap the benefits of the larger and extra highly effective winds that happen additional out to sea. Floating wind farms are anticipated to develop extra widespread over the subsequent decade. This is an particularly engaging choice for areas just like the Pacific Coast of the United States and the Mediterranean, the place the shores are deeper, versus the shallow waters of the Atlantic Coast of the U.S., U.Okay., and Norway. One vital requirement of floating OFW farms is the set up of dynamic, high-capacity submarine cables which might be capable of successfully harness and ship the generated electrical energy to our shores.

Figure 2. Offshore wind farms are anticipated to assist meet growing calls for for sustainable power.

Image by Ein Dahmer — Own work. Licensed underneath CC BY-SA 4.0, by way of Wikimedia Commons

Design Factors for Resilient Subsea Cables

Ever skilled slower than traditional web? Failure of a subsea cable could also be guilty. Cable failures of this type are a standard — and costly — prevalence, whether or not from the harm of mechanical stress and pressure brought on by bedrock, fishing trawlers, anchors, and issues with the cable design itself. As the offshore wind business continues to develop, our have to develop energy cables that may safely and effectively join these farms to our energy grid grows as nicely.

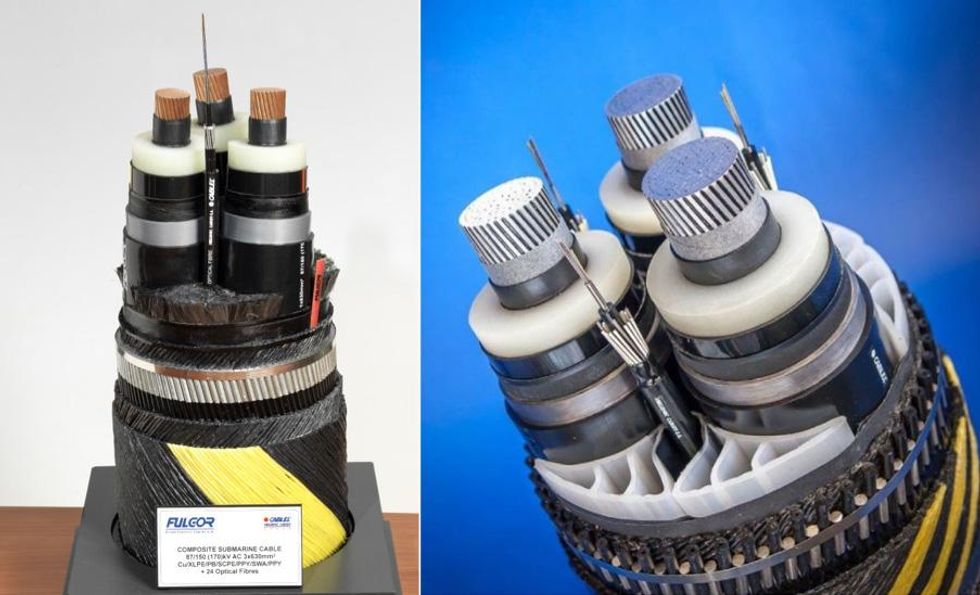

Before fixing or putting in a submarine cable, which may price billions of {dollars}, cable designers have to make sure that designs will carry out as meant in undersea circumstances. Today, that is sometimes finished with the assistance of computational electromagnetics modeling. To validate cable simulation outcomes, worldwide requirements are used, however these requirements haven’t been capable of sustain with current developments in computational energy and the simulation software program’s rising capabilities. Hellenic Cables, together with its subsidiary FULGOR, use the finite factor technique (FEM) to research their cable designs and evaluate them to experimental measurements, usually getting higher outcomes than what the worldwide requirements can provide.

Figure 3. Examples of three-core (3C) submarine cables out there from Hellenic Cables.

Updated Methodology for Calculating Cable Losses

The International Electrotechnical Commission (IEC) gives requirements for electrical cables, together with Standard 60287 1-1 for calculating cable losses and present scores. One drawback with the formulation utilized in Standard 60287 is that it overestimates cable losses — particularly the losses within the armor of three-core (3C) submarine cables. Cable designers are compelled to undertake a brand new methodology for performing these analyses, and the staff at Hellenic Cables acknowledges this. “With a more accurate and realistic model, significant optimization margins are expected,” says Dimitrios Chatzipetros, staff chief of the Numerical Analysis group at Hellenic Cables. The new methodology will allow engineers to scale back cable cross sections, thereby lowering their prices, which is the paramount objective for cable manufacturing.

An electrical cable is a posh machine to mannequin. The geometric construction consists of three fundamental energy cores which might be helically twisted with a specific lay size, and a whole lot of further wires — display screen or armor wires — which might be twisted with a second or third lay size. This makes it tough to generate the mesh and resolve for the electromagnetic fields. “This is a tedious 3D problem with challenging material properties, because some of the elements are ferromagnetic,” says Andreas Chrysochos, affiliate principal engineer within the R&D division of Hellenic Cables.

In current years, FEM has made an enormous leap in relation to cable evaluation. The Hellenic Cables staff first used FEM to mannequin a full cable part of round 30 to 40 meters in size. This turned out to be an enormous numerical problem that may solely realistically be solved on a supercomputer. By switching to periodic fashions with a periodic size equal to the cable’s cross pitch, the staff decreased the issue from 40 meters all the way down to 2–4 meters. Then they launched short-twisted periodicity, which reduces the periodic size of the mannequin from meters to centimeters, making it a lot lighter to unravel. “The progress was tremendous,” says Chrysochos. (Figure 4)

Although the enhancements that FEM brings to cable evaluation are nice, Hellenic Cables nonetheless must persuade its purchasers that their validated outcomes are extra lifelike than these supplied by the present IEC normal. Clients are sometimes already conscious of the truth that IEC 60287 overestimates cable losses, however outcomes visualization and comparability to precise measurements can construct confidence in challenge stakeholders. (Figure 5)

Finite Element Modeling of Cable Systems

Electromagnetic interference (EMI) presents a number of challenges in relation to designing cable techniques — particularly the capacitive and inductive couplings between cable conductors and sheaths. For one, when calculating present scores, engineers have to account for energy losses within the cable sheaths throughout regular operation. In addition, the overvoltages on cable sheaths should be inside acceptable limits to fulfill typical well being and security requirements.

As Chrysochos et al. talk about in “Capacitive and Inductive Coupling in Cable Systems – Comparative Study between Calculation Methods” (Ref. 3), there are three fundamental approaches in relation to calculating these capacitive and inductive couplings. The first is the advanced impedance technique (CIM), which calculates the cable system’s currents and voltages whereas neglecting its capacitive currents. This technique additionally assumes that the earth return path is represented by an equal conductor. Another frequent technique is electromagnetic transients program (EMT) software program, which can be utilized to research electromagnetic transients in energy techniques utilizing each time- and frequency-domain fashions.

The third technique, FEM, is the muse of the COMSOL Multiphysics software program. The Hellenic Cables staff used COMSOL Multiphysics and the add-on AC/DC Module to compute the electrical fields, currents, and potential distribution in conducting media. “The AC/DC Module and solvers behind it are very robust and efficient for these types of problems,” says Chrysochos.

The Hellenic Cables staff in contrast the three strategies — CIM, EMT software program, and FEM (with COMSOL Multiphysics) — when analyzing an underground cable system with an 87/150 kV nominal voltage and 1000 mm2 cross part (Figure 6). They modeled the magnetic discipline and induced present density distributions in and across the cable system’s conductors, accounting for the bonding sort with an exterior electrical circuit. The outcomes between all three strategies present good settlement for the cable system for 3 completely different configurations: stable bonding, single-point bonding, and cross bonding (Figure 7). This demonstrates that FEM will be utilized to all varieties of cable configurations and installations when considering each capacitive and inductive coupling.

The Hellenic Cables staff additionally used FEM to review thermal results in subsea cables, akin to HVAC submarine cables for offshore wind farms, as described in “Review of the Accuracy of Single Core Equivalent Thermal Model for Offshore Wind Farm Cables” (Ref. 4). The present IEC Standard 60287 1-1 features a thermal mannequin, and the staff used FEM to establish its weak spots and enhance its accuracy. First, they validated the present IEC mannequin with finite factor evaluation. They discovered that the present requirements don’t account for the thermal affect of the cable system’s metallic display screen supplies, which signifies that the temperature will be underestimated by as much as 8°C. Deriving analytical, correcting formulation based mostly on a number of FEM fashions, the staff decreased this discrepancy to 1°C! Their evaluation additionally highlights vital discrepancies between the usual and the FEM mannequin, particularly when the corresponding sheath thickness is small, the sheath thermal conductivity is excessive, and the ability core is massive. This situation is especially vital for OFW tasks, because the cables concerned are anticipated to develop bigger and bigger.

Further Research into Cable Designs

In addition to learning inductive and capacitive coupling and thermal results, the Hellenic Cables staff evaluated different facets of cable system designs, together with losses, thermal resistance of surrounding soil, and grounding resistance, utilizing FEM and COMSOL Multiphysics. “In general, COMSOL Multiphysics is much more user friendly and efficient, such as when introducing temperature-dependent losses in the cable, or when presenting semi-infinite soil and infinite element domains. We found several ways to verify what we already know about cables, their thermal performance, and loss calculation,” says Chatzipetros.

Losses

The conductor measurement of a subsea or terrestrial cable impacts the price of the cable system. This is commonly an important side of an offshore wind farm challenge. To optimize the conductor measurement, designers want to have the ability to precisely decide the cable’s losses. To accomplish that, they first turned to temperature. Currents induced in a cable’s magnetic sheaths yield additional losses, which contribute to the temperature rise of the conductor.

When calculating cable losses, the present IEC normal doesn’t contemplate proximity results in sheath losses. If cable cores are in shut proximity (say, for a wind farm 3C cable), the accuracy of the loss calculation is decreased. Using FEM, the Hellenic Cables staff was capable of examine how conductor proximity results affect losses generated in sheaths in submarine cables with lead-sheathed cores and a nonmagnetic armor. They then in contrast the IEC normal with the outcomes from the finite factor evaluation, which confirmed higher settlement with measured values from an experimental setup (Figure 8). This analysis was mentioned within the paper “Induced Losses in Non-Magnetically Armoured HVAC Windfarm Export Cables” (Ref. 5).

Thermal Resistance of Soil

Different soil sorts have completely different thermal insulating traits, which may severely restrict the quantity of warmth dissipated from the cable, thereby lowering its current-carrying capability. This signifies that bigger conductor sizes are wanted to transmit the identical quantity of energy in areas with extra thermally hostile soil, inflicting the cable’s price to extend.

In the paper “Rigorous calculation of external thermal resistance in non-uniform soils” (Ref. 6), the Hellenic Cables staff used FEM to calculate the efficient soil thermal resistance for various cable sorts and cable set up situations (Figure 9). First, they solved for the warmth switch drawback underneath steady-state circumstances with arbitrary temperatures on the cable and soil surfaces. They then evaluated the efficient thermal resistance based mostly on the warmth dissipated by the cable floor into the encircling soil.

Simulations had been carried out for 2 varieties of cables: a typical SL-type submarine cable with 87/150 kV, a 1000 mm2 cross part, and copper conductors, in addition to a typical terrestrial cable with 87/150 kV, a 1200 mm2 cross part, and aluminum conductors. The staff analyzed three completely different cable set up situations (Figure 10).

The first state of affairs is when a cable is put in beneath a horizontal layer, akin to when sand waves are anticipated to steadily add to the seafloor’s preliminary stage after set up. The second is when a cable is put in inside a horizontal layer, which happens when the set up takes place in a area with horizontal directional drilling (HDD). The third state of affairs is when a cable is put in inside a backfilled trench, typical for areas with unfavorable thermal conduct, with a view to scale back the affect of the soil on the temperature rise of the cable. The numerical modeling outcomes show that FEM will be utilized to any materials or form of multilayer or backfilled soil, and that the tactic is suitable with the present score methodology in IEC Standard 60287.

Grounding Resistance

The analysis of grounding resistance is vital to make sure the integrity and safe operation of cable sheath voltage limiters (SVLs) when topic to earth potential rise (EPR). In order to calculate grounding resistance, engineers have to know the soil resistivity for the issue at hand and have a strong calculation technique, like FEM.

The Hellenic Cables staff used FEM to research soil resistivity for 2 websites: one in northern Germany and one in southern Greece. As described within the paper “Evaluation of Grounding Resistance and Its Effect on Underground Cable Systems” (Ref. 7), they discovered that the obvious resistivity of the soil is a monotonic perform of distance, and {that a} two-layer soil mannequin is enough for his or her modeling drawback (Figure 11). After discovering the resistivity, the staff calculated the grounding resistance for a single-rod state of affairs (as a method of validation). After that, they proceeded with a posh grid, which is typical of cable joint pits present in OWFs. For each situations, they discovered the EPR on the substations and transition joint pit, in addition to the utmost voltage between the cable sheath and native earth (Figure 12). The outcomes reveal that FEM is a extremely correct calculation technique for grounding resistance, as they present good settlement with each numerical information from measurements and electromagnetic transient software program calculations (Figure 13).

A Bright and Windy Future

The Hellenic Cables staff plans to proceed the vital work of additional enhancing the entire cable fashions they’ve developed. The staff has additionally carried out analysis into HVDC cables, which contain XLPE insulation and voltage supply converter (VSC) know-how. HVDC cables will be extra price environment friendly for techniques put in over lengthy distances.

Like the wind used to energy offshore wind farms, electrical cable techniques are throughout us. Even although we can’t all the time see them, they’re working exhausting to make sure we have now entry to a high-powered and well-connected world. Optimizing the designs of subsea and terrestrial cables is a crucial a part of constructing a sustainable future.

References

- M. Hatlo, E. Olsen, R. Stølan, J. Karlstrand, “Accurate analytic formula for calculation of losses in three-core submarine cables,” Jicable, 2015.

- S. Sturm, A. Küchler, J. Paulus, R. Stølan, F. Berger, “3D-FEM modelling of losses in armoured submarine power cables and comparison with measurements,” CIGRE Session 48, 2020.

- A.I. Chrysochos et al., “Capacitive and Inductive Coupling in Cable Systems – Comparative Study between Calculation Methods”, tenth International Conference on Insulated Power Cables, Jicable, 2019.

- D. Chatzipetros and J.A. Pilgrim, “Review of the Accuracy of Single Core Equivalent Thermal Model for Offshore Wind Farm Cables”, IEEE Transactions on Power Delivery, Vol. 33, No. 4, pp. 1913–1921, 2018.

- D. Chatzipetros and J.A. Pilgrim, “Induced Losses in Non-Magnetically Armoured HVAC Windfarm Export Cables”, IEEE International Conference on High Voltage Engineering and Application (ICHVE), 2018.

- A.I. Chrysochos et al., “Rigorous calculation of external thermal resistance in non-uniform soils”, Cigré Session 48, 2020.

- A.I. Chrysochos et al., “Evaluation of Grounding Resistance and Its Effect on Underground Cable Systems”, Mediterranean Conference on Power Generation, Transmission , Distribution and Energy Conversion, 2020.