[ad_1]

This sponsored article is dropped at you by COMSOL.

India is a fast-growing marketplace for electrical automobiles (EVs), with one examine predicting that over 30 % of the automobiles bought in India shall be electrical by 2030 (Ref. 1). The battery packs that energy EVs are one of many predominant drivers of the electrical mobility revolution in India. In order to observe and handle battery pack efficiency and security, packs are normally outfitted with a battery administration system (BMS). A BMS is an digital system that displays a battery’s voltage, temperature, coolant circulation, and well being and predicts quite a few different efficiency parameters, similar to present variation and warmth era, serving to to extract optimum efficiency from a battery pack.

The Role of Simulation in Developing Accurate BMS

Exicom Tele-Systems Pvt. Ltd. designs, develops, and deploys power options, together with the newest Li-ion battery applied sciences. To date, it has deployed Li-ion battery options totaling greater than 1.8 GWh — among the many highest on the planet by a single firm. Exicom additionally provides charging options and BMS for electrical two-wheelers and lightweight electrical automobiles, that are driving the expansion of electrical mobility in India. Exicom’s modern BMS options are prized for his or her efficiency and life.

At Exicom’s R&D heart in Gurugram, India, the know-how workforce led by Dr. Parmender Singh has developed a BMS that can be utilized to exactly monitor and handle Li-ion batteries in functions throughout a broad voltage vary (as much as 1000 V). This BMS can be chemistry agnostic; it may be used with Li-ion batteries of a variety of chemistries similar to lithium ferrophosphate, or lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium nickel cobalt aluminum oxide (NCA).

For India’s transportation sector to satisfy its formidable electrification targets, producers should speed up the event of important elements, similar to battery administration methods (BMS)

The precision of the BMS is dependent upon the standard and accuracy of the inputs used for programming or calibrating the system. For instance, the BMS contains quite a few thermal sensors distributed throughout the battery pack. In order to precisely monitor a battery pack’s temperature distribution and predict corresponding efficiency, it’s crucial that the sensors be positioned on the proper areas. This requires an in depth understanding of the warmth profile of every battery cell in addition to how warmth varies all through the pack. This is the place COMSOL Multiphysics performs an integral half, by permitting for correct computation and collation of the inputs, like warmth profile info, which can be required to develop a BMS with surgical precision.

Predicting and Preventing Potential Thermal Runaway

Dr. Singh’s workforce at Exicom used COMSOL Multiphysics to carry out quite a few analyses on the thermal habits of battery cells. They additionally used simulation to investigate potential exterior brief circuits, which may trigger thermal runaway — an uncontrolled self-heating course of that may harm gear and even trigger fires. The Exicom workforce started by analyzing the warmth generated in cylindrical cells with completely different kind components and additional prolonged this mannequin to the pack stage utilizing the warmth profile generated for the cells. “We were especially interested in improving the temperature gradient across the pack for air-cooled battery packs,” stated Dr. Singh.

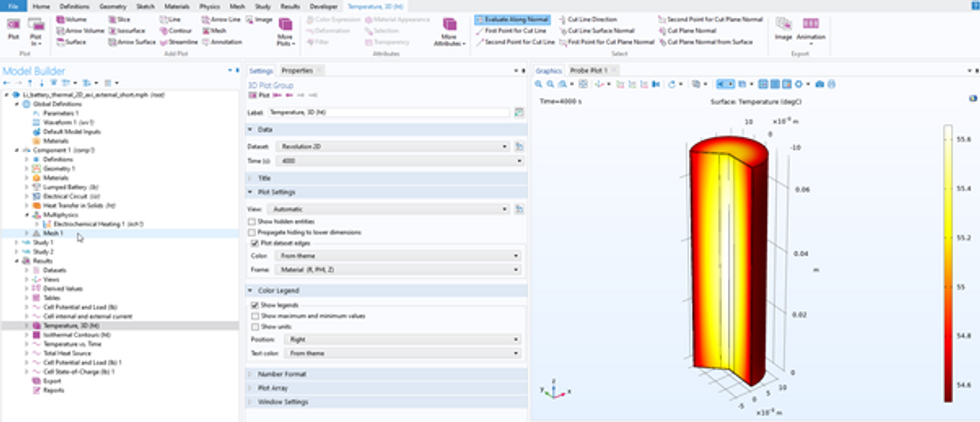

The outcomes for thermal modeling on the cell stage for cylindrical cells throughout a 1C discharging are proven in Figure 1. The visualization on the left in Figure 1 exhibits the temperature distribution, the place the utmost temperature is noticed in the midst of the cell. The visualization on the best exhibits the contour distribution of temperature, the place the utmost temperature is situated within the lively materials of the cell.

The simulation outcomes, when validated with experimental findings, had been noticed to be throughout the error limits of ±5 % at the usual cost–discharge profile. The mannequin was then additional prolonged for 2C discharge at one hundred pc state of cost (SOC) in keeping with Standard UL1642, which is outlined for exterior brief circuit testing.

The constructive and damaging terminals of the cell had been shorted by way of an 80 ±20 mΩ resistance. The COMSOL software program’s lumped approach-based thermal mannequin was validated in opposition to experimental information for cost–discharge profiles of the cell. They additionally developed:

- Cyclic and calendric capacity-fade fashions for cylindrical cells primarily based on the optimization options obtainable in COMSOL

- A high-fidelity pseudo two-dimensional (P2D) mannequin for cylindrical cells utilizing extracted electrochemical parameters

They discovered that the lumped method enabled them to assemble fashions utilizing a minimal variety of parameters — similar to cell geometry, electrode thickness, thermal conductivity, warmth capability, drive cycle, and open-circuit voltage (OCV)-SOC desk — which can be available from battery pack producers.

Extracting these parameters experimentally isn’t solely a time-consuming course of but additionally susceptible to errors attributable to variable experimental circumstances. For instance, ambient temperature fluctuates, so extracting an correct warmth profile of a cell requires performing an in depth sequence of exams at completely different ambient temperatures. Using simulation, nonetheless, Dr. Singh and the workforce had been in a position to carry out these experiments with nice ease. They had been in a position to effectively examine cost and discharge profiles, thermal habits at completely different cost and discharge charges, and thermal runaway attributable to exterior or inside brief circuits for various cell chemistries. They had been additionally in a position to determine the hotspots within the battery pack and decide the cell grading primarily based on capability fade evaluation with excessive accuracy. These outcomes had direct functions in lowering the event cycle time of the BMS, because the hotspots indicated the perfect positions for deploying the thermal sensors throughout the BMS with a view to perform most effectively. According to Dr. Singh, “COMSOL is an easy-to-learn and adaptable finite element tool for battery design and thermal modeling.”

Figure 4. The COMSOL Multiphysics consumer interface exhibiting a battery mannequin.

Future Scope: Extending Battery Simulations to Predict Aging

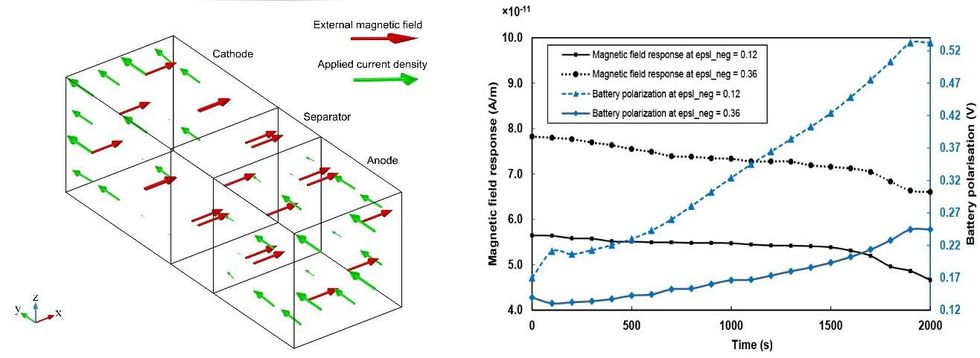

In addition to the thermal simulations, Dr. Singh has expanded the usage of simulations to research one other essential phenomenon: battery growing old. During the lifetime of a battery, its state of well being (SOH) progressively deteriorates attributable to irreversible bodily and chemical adjustments, similar to the expansion of a strong electrolyte interphase (SEI) layer, which might result in lack of porosity in a battery cell, which in flip can result in a rise in polarization and inside resistance. Magnetic area probing (MFP) is a noninvasive technique for monitoring a battery’s SOH. With the purpose of demonstrating the potential of the MFP technique, Dr. Singh developed a multiphysics mannequin in COMSOL to judge the magnetic area response, battery polarization, and inside resistance of the Li-ion battery (Ref. 2). The workforce noticed that variation in electrode porosity has a big affect on the magnetic area response. Though this analysis is at the moment in its preliminary phases, the potential functions are far reaching. “We expect that further investigation into this phenomenon will allow for developing and deploying monitoring features for battery aging as well as better protection mechanisms against it in the BMS itself,” stated Dr. Singh.

Figure 5. 3D-designed cell geometry (left). Variation of magnetic area response and polarization habits throughout discharging at 0.12 and 0.36 anode porosity values (proper).

The Exicom workforce is at the moment engaged on electrochemical P2D modeling for thermal and capacity-fading evaluation on the cell stage. It intends to additional lengthen the mannequin with further thermal exothermic equations on the electrodes and SEI layer for higher accuracy throughout thermal runaway. They additionally plan to make use of the lumped capability fade mannequin for cyclic and calendric predictive evaluation. In the long run, in addition they plan to implement a decreased order mannequin for SOC and SOH and export the mannequin to MATLAB for code era as much as the ASIC stage.

With the accelerating transition to electrical mobility in India and worldwide, analysis on battery know-how is anticipated to extend considerably within the coming years. Simulation software program like COMSOL provides a vital head begin to corporations within the electrical mobility house that wish to present simpler options and enhance the time to marketplace for their merchandise.

References

- S. Sen, “30% vehicles in India will be electric by 2030: Study,” The Times of India, 17 Jun. 2022; https://timesofindia.indiatimes.com/city/mumbai/30-vehicles-in-india-will-be-electric-by-2030-study/articleshow/92265373.cms.

- P. Singh et al., “Li-Ion Battery Aging Parameter: Porosity Behavior Analysis Using Magnetic Field Probing,” ECS Meeting Abstracts, vol. MA2021-02, 2021, no. 3, p. 294, 2021.

MATLAB is a registered trademark of The MathWorks, Inc.

[ad_2]