[ad_1]

Communication & Safety Challenges Facing Mobile Robots Manufacturers

Mobile robots are in every single place, from warehouses to hospitals and even on the road. Their reputation is straightforward to grasp; they’re cheaper, safer, simpler to search out, and extra productive than precise employees. They’re simple to scale or mix with different machines. As cellular robots accumulate a number of real-time knowledge, firms can use cellular robots to start out their IIoT journey.

But to work effectively, cellular robots want secure and dependable communication. This article outlines the primary communication and security challenges going through cellular robotic producers and gives a straightforward solution to overcome these challenges to maintain cellular robots transferring.

What are Mobile Robots?

Before we start, let’s outline what we imply by cellular robots.

Mobile robots transport supplies from one location to a different and are available two sorts, automated guided automobiles (AGVs) and autonomous cellular robots (AMRs). AGVs use guiding infrastructure (wires reflectors, reflectors, or magnetic strips) to comply with predetermined routes. If an object blocks an AGV’s path, the AGV stops and waits till the item is eliminated.

AMRs are extra dynamic. They navigate by way of maps and use knowledge from cameras, built-in sensors, or laser scanners to detect their environment and select probably the most environment friendly route. If an object blocks an AMR’s deliberate route, it selects one other route. As AMRs aren’t reliant on guiding infrastructure, they’re faster to put in and might adapt to logistical adjustments.

What are the Communication and Safety Challenges Facing Mobile Robot Manufacturers?

1. Establish a Wireless Connection

The first problem for cellular robotic producers is to pick out probably the most appropriate wi-fi know-how. The standard recommendation is to ascertain the necessities, consider the requirements, and select the very best match. Unfortunately, this isn’t at all times attainable for cellular robotic producers as usually they don’t know the place the machine might be situated or the precise particulars of the goal utility.

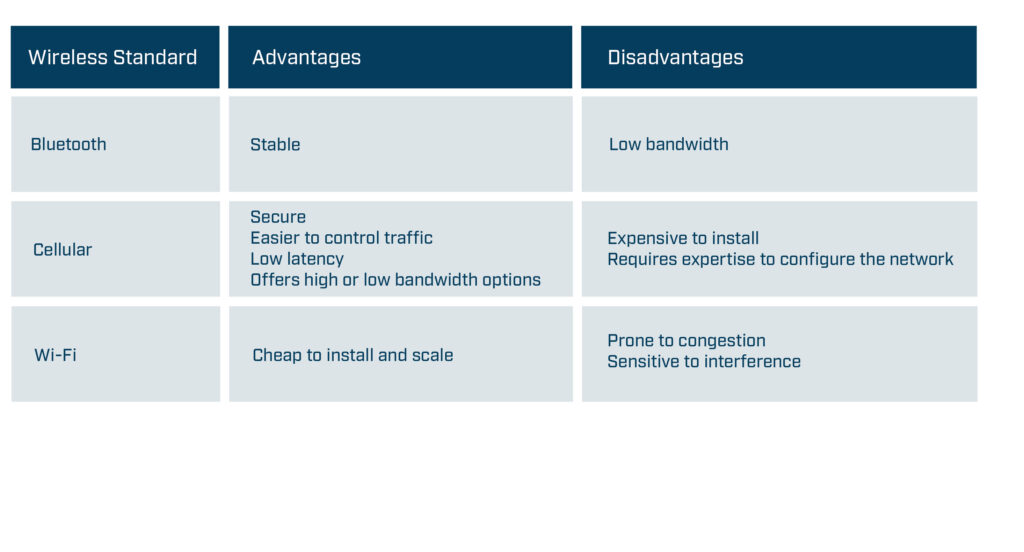

Sometimes a Bluetooth connection might be splendid because it gives a secure non-congested connection, whereas different functions would require a high-speed, safe mobile connection. What can be helpful for cellular robotic producers is to have a networking know-how that’s simple to alter to fulfill particular necessities.

Wireless commonplace -high-level benefits and drawbacks

The second problem is to make sure that the set up works as deliberate. Before putting in a wi-fi resolution, full a predictive web site survey primarily based on facility drawings to make sure the cellular robots have enough sign protection all through the situation. The web site survey ought to establish the optimum location for the Access Points, the proper antenna sort, the optimum antenna angle, and the right way to mitigate interference. After the set up, use wi-fi sniffer instruments to verify the design and regulate APs or antenna as required.

2. Connecting Mobile Robots to Industrial Networks

Mobile robots want to speak with controllers on the related web site though the cellular robots and controllers are sometimes utilizing completely different industrial protocols. For instance, an AGV may use CANopen whereas the controller may use PROFINET. Furthermore, cellular robotic producers might need to use the identical AGV mannequin on a unique web site the place the controller makes use of one other industrial community, similar to EtherCAT.

Mobile robotic producers additionally want to make sure that their cellular robots have enough capability to course of the required quantity of information. The required quantity of information will differ relying on the scale and kind of set up. Large installations might use extra knowledge because the routing algorithms have to cowl a bigger space, extra automobiles, and extra potential routes. Navigation techniques similar to imaginative and prescient navigation course of photographs and due to this fact require extra processing energy than installations utilizing different navigation techniques similar to reflectors. As a outcome, cellular robotic producers should remedy the next challenges:

- They want a networking know-how that helps all main fieldbus and industrial Ethernet networks.

- It must be simple to alter the networking know-how to allow the cellular robotic to speak on the identical industrial community because the controller with out altering the {hardware} design.

- They want to make sure that the networking know-how has enough capability and performance to course of the required knowledge.

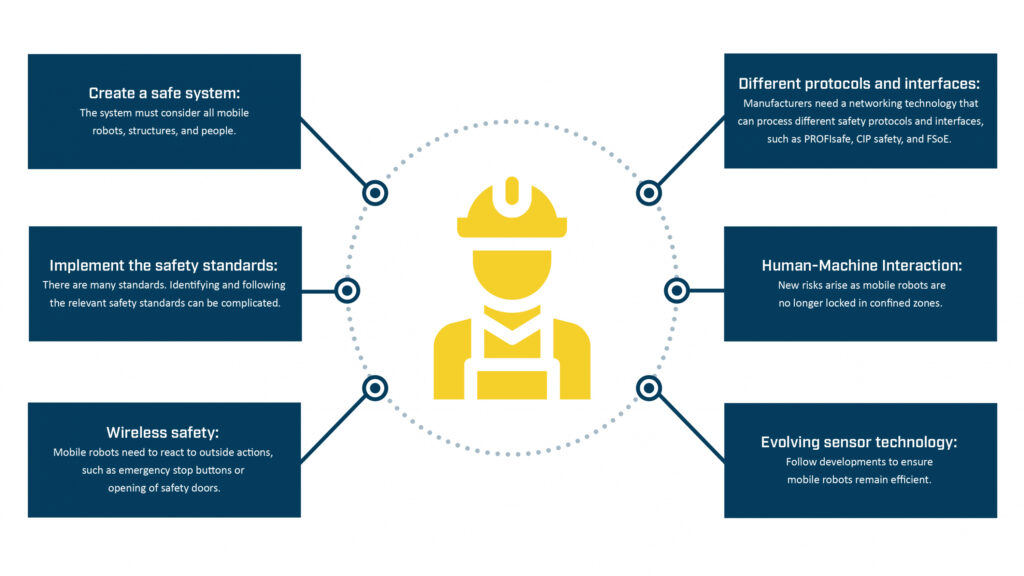

3. Creating a Safe System

Creating a system the place cellular robots can safely transport materials is a crucial however difficult activity. Mobile robotic producers have to create a system that considers all the various kinds of cellular robots, buildings, and folks within the setting. They want to make sure that the cellular robots react to exterior actions, similar to somebody opening a security door or pushing an emergency cease button, and that the networking resolution can course of completely different security protocols and interfaces. They want to contemplate that AMRs transfer freely and handle the chance of collisions accordingly. The know-how utilized in sensors is continually evolving, and cellular robotic producers have to comply with the developments to make sure their merchandise stay as environment friendly as attainable.

Overview of Safety Challenges for Mobile Robot Manufacturers

Safety Standards

The security requirements present pointers on implementing safety-related elements, making ready the setting, and sustaining machines or tools.

While compliance with the completely different security requirements (ISO, DIN, IEC, ANSI, and so on.) is generally voluntary, machine builders within the European Union are legally required to comply with the security requirements within the equipment directives. Machinery directive 2006/42/EC is at all times relevant for cellular robotic producers, and in some functions, directive 2014/30/EU may additionally be related because it regulates the electromagnetic compatibility of apparatus. Machinery directive 2006/42/EC describes the necessities for the design and building of secure machines launched into the European market. Manufacturers can solely affix a CE label and ship the machine to their clients if they’ll show within the declaration of conformity that they’ve fulfilled the directive’s necessities.

Although the opposite security requirements aren’t necessary, producers ought to nonetheless comply with them as they assist to meet the necessities in equipment directive 2006/42/EC. For instance, producers can comply with the steering in ISO 12100 to cut back recognized dangers to a suitable residual threat. They can use ISO 13849 or IEC 62061 to search out the required security stage for every threat and be certain that the corresponding safety-related operate meets the outlined necessities. Mobile robotic producers determine how they obtain a sure security stage. For instance, they’ll lower the velocity of the cellular robotic to decrease the chance of collisions and severity of accidents to a suitable stage. Or they’ll be certain that cellular robots solely function in separated zones the place human entry is prohibited (outlined as confined zones in ISO 3691-4).

Identifying the proper requirements and implementing the necessities is one of the best ways cellular producers can create a secure system. But as this abstract suggests, it’s an advanced and time-consuming course of.

4. Ensuring a Reliable CAN Communication

A dependable and easy-to-implement commonplace for the reason that Eighties, communication-based on CAN know-how continues to be rising in reputation, primarily attributable to its use in numerous booming industries, similar to E-Mobility and Battery Energy Storage Systems (BESS). CAN is straightforward, vitality and cost-efficient. All the gadgets on the community can entry all the knowledge, and it’s an open commonplace, which means that customers can adapt and lengthen the messages to fulfill their wants.

For cellular robotic producers, establishing a CAN connection is changing into much more very important because it permits them to observe the lithium-ion batteries more and more utilized in cellular robotic drive techniques, both in retrofit techniques or in new installations. Mobile robotic producers have to do the next:

1.Establish a dependable connection to the CAN or CANopen communication requirements to allow them to verify their gadgets, similar to monitoring the battery’s standing and efficiency.

2. Protect techniques from electromagnetic interference (EMI), as EMI can destroy a system’s electronics. The threat of EMI is important in retrofits as including new elements, similar to batteries subsequent to the communication cable, leads to the introduction of high-frequency electromagnetic disturbances.

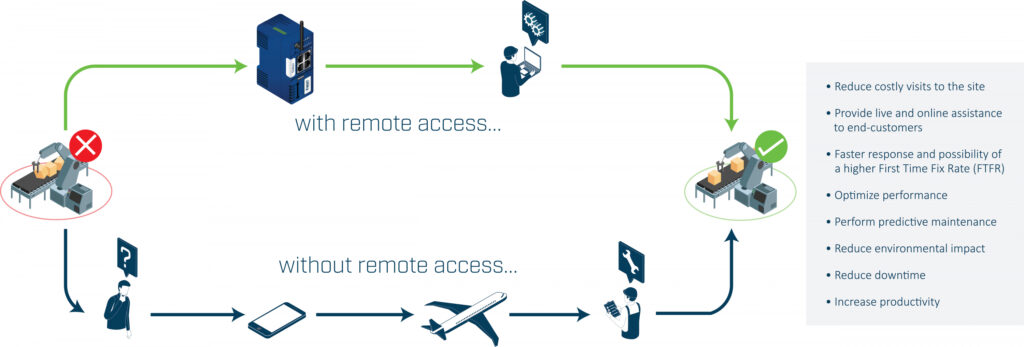

5. Accessing Mobile Robots Remotely

The capacity to remotely entry a machine’s management system can allow cellular robotic distributors or engineers to troubleshoot and resolve most issues with out touring to the positioning.

Benefits of Remote Access

The problem is to create a distant entry resolution that balances the wants of the IT division with the wants of the engineer or vendor.

The IT division needs to make sure that the community stays safe, dependable, and retains integrity. As a outcome, the distant entry resolution ought to embrace the next safety measures:

- Use outbound connections relatively than inbound connections to maintain the affect on the firewall to a minimal.

- Separate the related site visitors from the remainder of the community.

- Encrypt and defend all site visitors to make sure its confidentiality and integrity.

- Ensure that distributors work according to or are licensed to related safety requirements similar to ISO 27001

- Ensure that suppliers full common safety audits.

The engineer or vendor needs an easy-to-use and reliable system. It ought to be simple for customers to hook up with the cellular robots and entry the required info. If the set up may change, it ought to be simple to scale the variety of robots as required. If the cellular robots are in a unique nation from the distributors or engineers, the networking infrastructure should have enough protection and redundancy to ensure availability worldwide.

Conclusion

As we’ve seen, cellular robotic producers should remedy many communication and security challenges. They should set up a wi-fi connection, ship knowledge over completely different networks, guarantee security, hook up with CAN techniques, and securely entry the robots remotely. And to make it extra sophisticated, every set up have to be re-assessed and tailored to fulfill the on-site necessities.

Best observe to implement cellular robotic communication

Mobile robotic producers are not often communication or security consultants. Subsequently, they’ll discover it time-consuming and costly to try to develop the required communication know-how in-house. Enlisting purpose-built third-party communication options not solely solves the communication challenges at hand, it additionally gives different advantages.

Modern communication options have a modular design enabling cellular robotic producers to take away one networking product designed for one commonplace or protocol and substitute it with a product designed for a unique commonplace or protocol with out impacting every other a part of the machine. For instance, Bluetooth would be the best suited wi-fi commonplace in a single set up, whereas Wi-Fi might present higher protection in one other set up. Similarly, one web site might use the PROFINET and PROFIsafe protocols, whereas one other might use completely different industrial and security protocols. In each eventualities, cellular robotic producers can use communication merchandise to alter the networking know-how to fulfill the native necessities with out making any adjustments to the {hardware} design.

Authors:

Mark Crossley, Daniel Heinzler, Fredrik Brynolf, Thomas Carlsson

HMS Networks

HMS Networks is an industrial communication knowledgeable primarily based in Sweden, offering a number of options for AGV communication. Read extra on www.hms-networks.com/agv