[ad_1]

Jonathan Gitlin

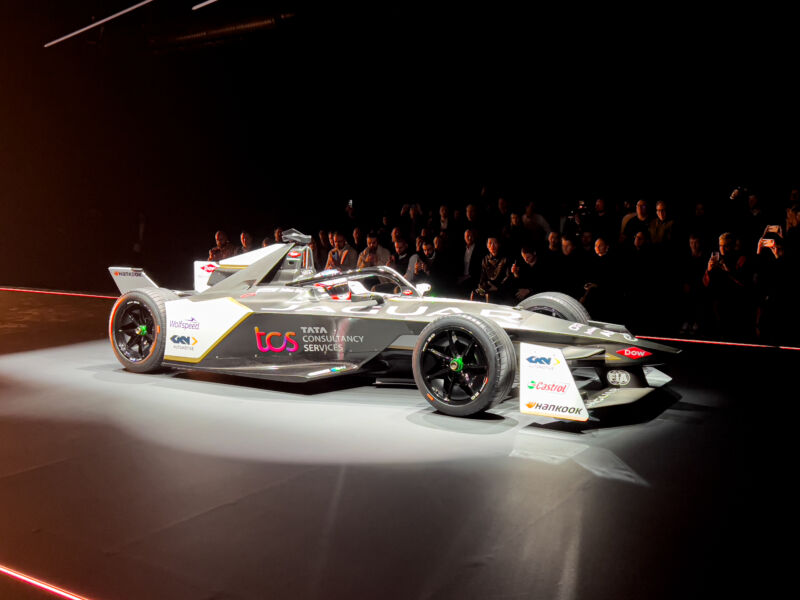

LONDON—On Wednesday, Jaguar Racing turned the newest Formula E crew to unveil its race automotive for the approaching season. The sport has radical new technical guidelines for its third-generation race automotive, which is smaller, lighter, extra highly effective, and extra environment friendly. This would be the British automaker’s sixth season competing within the sequence, and its participation is for extra than simply advertising and marketing; Jaguar Land Rover’s electrified street automobiles have benefited in tangible methods consequently, in accordance with the crew’s technical supervisor Phil Charles.

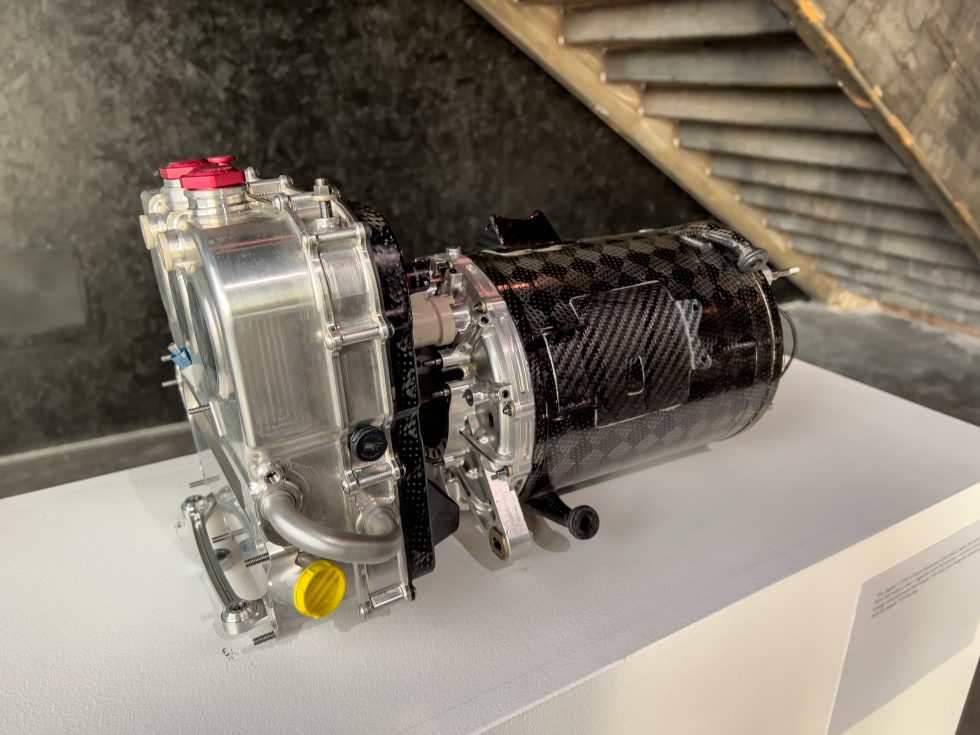

“If you rewind again to 2017, that is the primary time that [we used] our in-house inverter for the racing crew,” Charles informed Ars. “We put a silicon carbide switching machine, the Wolfspeed one truly… that gave us the flexibility to change tremendous quick. That was the push on our facet—we need to change quicker and see if that may give us effectivity, which it did. So we have gotten time and again and over throughout these inverter growth cycles, switching quicker and quicker and quicker,” he mentioned.

At the time, few producers checked out silicon carbide energy electronics for road-going EVs. “Now everybody needs silicon carbide, and the rationale they need it’s the identical causes we do,” Charles mentioned. “So the tech that we pushed then has actually caught up now—the race to street is admittedly clear. If I type of map our switching pace improve, we have finished 5 evolutions with totally different topologies of the in-house inverter. Now the street automobiles are coming alongside and the profit there’s vary, in the end; it means smaller batteries.”

A grievance that is been leveled at Formula E prior to now is that the technical guidelines restrict the quantity of analysis and growth that is doable because of a excessive variety of spec parts just like the chassis and battery. Indeed, this was cited as a cause by Audi and BMW to withdraw from the game. But Charles sees it in another way.

Jonathan Gitlin

“It’s so loopy the technical freedom now we have bought. On the software program facet—fully free. On the motor and inverter—fully free, only a energy restrict. So we simply may go fully bananas, and that is the outcome that you simply get now. I’m speaking with my Jaguar Land Rover colleagues on a regular basis as a result of they’re taking a look at us, going, “Wow, you probably did that. That’s actually cool. How did you take care of that? What was the issue?” And it sounds foolish, however all these classes that we realized, all of the errors we have made, are shortcuts for these guys,” he mentioned.

An instance of a type of classes was the necessity to protect digital parts. “As you turn quicker, the EMI that is given off from these switching gadgets will get increasingly more and extra, and also you begin turning off your different programs on the racecar,” Charles defined. “So we did a number of technical coatings within the first unit, quite simple mechanical issues to start out with, the place we tried to cease these parts, the EMI getting exterior of the inverter,” he continued.

Other classes have concerned drivability. “You’ve bought such excessive functionality to ship torque so shortly, and the drivability that the drivers really feel may be very intently linked to how effectively you management now, so you may ship [torque] immediately. It’s not like you have to flip the engine to ship extra shortly, we’re delivering shortly already, however we bought very correct or very sturdy and fast functionality to maneuver the goal,” Charles mentioned.