[ad_1]

CNC machines are a staple in lots of factories and workshops. They are a core know-how for creating precision components and merchandise.

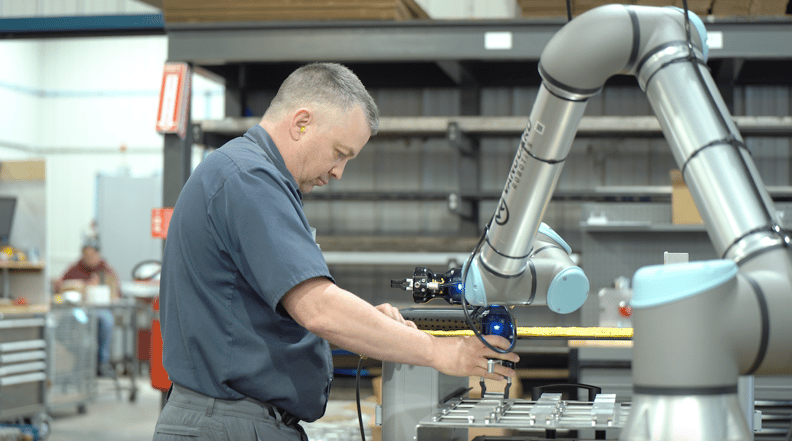

Automating a CNC machine may help you enhance its productiveness and machine utilization, whereas liberating up your operators for extra advanced, rewarding duties. It reduces the necessity for human operators to be standing over the machine for a lot of hours merely to load and unload the machine.

There are many forms of CNC machines. You may use a number of of them in your personal manufacturing processes. Each machine has its personal distinctive operate and objective. Some are simpler to automate than others, however all can profit from added automation in the suitable circumstances.

In this text, you’ll study how one can automate numerous CNC machines utilizing robotic automation.

The similarities between most CNC machines

At their core, most CNC machines comprise the identical fundamental elements. For this cause, automating virtually any kind of CNC machines includes an analogous course of.

These widespread elements are:

-

The enclosure — This homes the remainder of the CNC machine elements, aside from the controller, which is normally mounted on the skin. A guide or semi-automatic door is used to entry the within of the machine.

-

The machine mattress — This is the inspiration of the machine on which all different elements are mounted. It helps the burden of the opposite elements and the workpiece being machined.

-

The work head — This holds and strikes the software. Depending on the kind of CNC machine, it might transfer in numerous instructions.

-

The software — This is the “enterprise finish” of the CNC machine — it performs the slicing, shaping, or different course of activity on the workpiece. It is mounted to the top of the work head and might be modified to go well with the duty.

-

The controller — This homes the electronics and software program that controls the machine. You can program it utilizing a pc or straight by means of the controller display screen.

Any automation resolution might want to interface indirectly with these elements. Usually, the robotic’s controller will interface with the controller electronically. The robotic will place workpieces onto the machine mattress.

How to automate virtually any CNC machine with a robotic

You can automate virtually any CNC machine with a robotic, although some are simpler to combine with an automation resolution than others.

The best technique to automate a CNC machine is with a robotic utility equipment for machine tending. This will embrace all of the {hardware} and software program parts that you will want to automate your machine with a robotic.

Robotiq Machine Tending Solution makes use of an ingenious methodology of machine communication to permit it to simply combine with virtually any CNC lathe or milling machine — it makes use of the identical buttons, lights, and switches {that a} human operator makes use of to work together with the machine. This considerably reduces the combination work required in comparison with extra standard options.

The steps to combine virtually any CNC machine with a robotic are:

-

Choose the kind of CNC machine you need to automate.

-

Use the Robotiq Machine Tending Configurator to configure your particular utility equipment (or get in contact in case your machine kind is not listed within the configurator).

-

Install the equipment and configure the software program utilizing the easy Machine Tending Wizard on the display screen.

-

Deploy the robotic in your manufacturing line.

-

Monitor the outcomes and use your learnings to deploy your subsequent CNC machine tending robotic.

15 forms of CNC machines you may automate with a robotic

There are many CNC machines accessible. Some, like lathes and milling machines, will work out of the field with an utility equipment. Others may require extra customized automation.

Here are 15 widespread forms of CNC machine:

-

Lathe — This is used to create exact, symmetrical components and merchandise from a wide range of supplies together with metals, plastics, and wooden.

-

Milling machine — This cuts and shapes supplies utilizing a rotating slicing software. It’s generally used to create intricate designs and shapes for a wide range of functions.

-

Router — A router is sort of a milling machine however it’s sometimes smaller. It’s used to chop and form wooden, plastic, and steel. It is used for functions like engraving or carving indicators.

-

Plasma cutter — This makes use of a high-velocity stream of scorching plasma to chop by means of steel, for functions like industrial development, restoration, and salvage operations.

-

Laser cutter — A laser cutter makes use of a concentrated beam of sunshine to chop by means of materials. Common functions embrace the creation of indicators and ornamental engraving.

-

Waterjet cutter — This makes use of a high-pressure stream of water to chop by means of supplies. Applications embrace slicing of stones, tiles, glass, and steel.

-

Oxy-fuel cutter — This makes use of a mixture of oxygen and gas to chop by means of steel. One widespread utility is the creation of plate edges for groove and bevel welding.

-

Punch press — This makes use of a die to chop or form materials. Common makes use of embrace the creation of countersinks, embossments, extrusions, and louvres.

-

Bending machine — This is used to bend or fold sheet steel. Applications embrace bending of brackets, clamps, and product covers.

-

Shearing machine — This cuts sheet steel utilizing blades. Application areas embrace the automotive and aerospace industries.

-

Press brake — This bends or folds sheet steel utilizing a die. Such machines are sometimes used in marine engineering, steel art work manufacturing, and furnishings manufacture.

-

Turret press — This is a kind of punch press that has a rotating turret that holds the dies. Common makes use of embrace the creation of stamped options akin to louvers, card guides, lances, electrical knockouts, and dimples.

-

Hydraulic press — This makes use of hydraulic fluid to use power to an object. Commonly utilized in a bunch of utility areas, together with transportation, power, and transportation.

-

Electric discharge machine — This makes use of electrical pulses to chop by means of steel. Common makes use of embrace mould and die making, small gap drilling, and medical part manufacture.

-

Grinding machine — This grinds or polishes surfaces. Commonly used for basic machining duties and automotive half manufacturing.

These are simply a few of the most typical forms of CNC machines. There are many others which might be used for particular duties and industries.

.jpg?width=820&height=460&name=Hugo+3cobots%20(4).jpg)

How to Automate Your Specific CNC Machine

It does not matter what kind of CNC you might have, you may virtually definitely automate it indirectly.

If you’re utilizing a standard CNC machine, like a lathe or milling machine, you should use an answer just like the Robotiq Machine Tending Solution straight out of the field.

For different forms of machine, get in contact and we may help you out.

What kind of machine would you prefer to automate? Tell us within the feedback beneath or be part of the dialogue on LinkedIn, Twitter, Facebook, or the DoF skilled robotics neighborhood.