[ad_1]

News briefs for the week check out robots and cobots in automated and semi-automated laboratories, in what’s now known as Pharma 4.0. From drug discovery, to the manufacturing and packaging of recent prescription drugs, the wedding of AI and robotics has been essential to the method. It’s a brand new world for robots and cobots, and they’re proving themselves as much as the duty, after which some.

Robots & cobots provide Pharma 4.0

Robots and cobots, increasingly, are starting to exert an outsized affect on life-saving and disease-preventing new drug discoveries, medicines, and therapeutics.

Although specialised laboratory robots have been round for the reason that Nineteen Eighties when Zymark Corporation first launched them, uptake has been sluggish. “The pharmaceutical industry has been slow to adopt robotic technology compared with its manufacturing peers,” writes Lars Olsen in TechTalk. “But with the FDA encouraging the use of innovative technologies, it’s only a matter of time before the use of robotics in biotech goes from first-mover to standard.”

Although specialised laboratory robots have been round for the reason that Nineteen Eighties when Zymark Corporation first launched them, uptake has been sluggish. “The pharmaceutical industry has been slow to adopt robotic technology compared with its manufacturing peers,” writes Lars Olsen in TechTalk. “But with the FDA encouraging the use of innovative technologies, it’s only a matter of time before the use of robotics in biotech goes from first-mover to standard.”

Moderna, for instance, leaned closely on robots to fulfill its COVID-19 vaccine deadlines. Dave Johnson, chief knowledge and synthetic intelligence officer at Moderna, recollects Moderna’s conversion to digital: “One of the big bottlenecks was having mRNA for the scientist to run tests in. So, what we did is we put in place a ton of robotic automation, put in place a lot of digital systems and process automation and AI algorithms as well.”

The digital transformation of those labs by way of automated, AI-driven robotics is being known as Pharma 4.0 (sound acquainted?)

Here’s a video overview of laboratory transformation:

Turns out, pharma, therapeutics, and biomedicine labs are excellent locations for robots and cobots. Robots and cobots provide tireless labor and error-free productiveness that’s quicker, extra correct, and cheaper than people.

For instance, German biotechnology firm Evotec, introduced a brand new anticancer molecule from its work with UK-based Exscientia that applies synthetic intelligence (AI) strategies to small-molecule drug discovery. A discovery made doable partially to robots that lower pattern testing from 4 to five years to eight months.

In one rising subject, robots and AI are starting to associate to swiftly course of tens of millions of molecules whereas looking for transformative new therapies by digital biology. One pharma-tech firm, XtalPi, is even including quantum physics to the AI, robotic discovery search.

In many instances, if it weren’t for robots, therapeutics similar to Evotec’s wouldn’t be saving lives for one more 4 to five years.

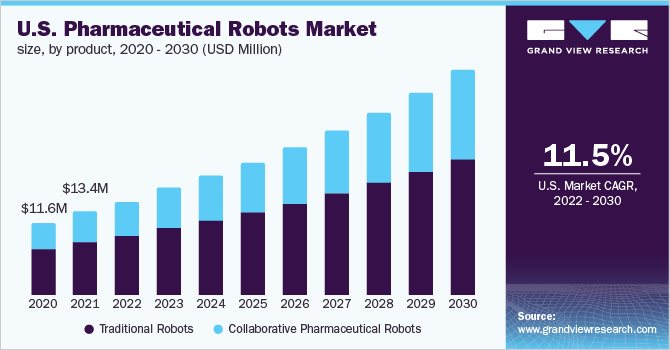

And the near-term future for robots and cobots in labs seems even brighter. In truth, the forecast is close to mind-boggling. The 10-year leap from 2020 to 2030 sees almost a tripling of business robotic and cobot gross sales within the U.S. (see chart beneath).

Worldwide, in response to Grandview Research, “the worldwide pharmaceutical robots market dimension was valued at $162.7 million in 2021 and is predicted to broaden at a compound annual development price (CAGR) of 9.2% from 2022 to 2030.

“The rising want for automation in manufacturing models, coupled with the excessive prices of recent drug discovery, is considerably growing the demand for robotics in scientific trials, drug discovery, and laboratories for automating the procedures.

“In addition, key companies are introducing technologically advanced robotic machines, which has further led to the tremendous growth of the market. With rising demands for precision, output, and faster turnaround times, automation and robotics have gained traction in the pharmaceutical industry.”

There’s an ever-growing listing of these within the AI drug discovery house shortly onboarding robots to higher allow and speed up the method: Recursion Pharmaceuticals, Arctoris, Insitro, Relay Therapeutics, and Insilico Medicine are the pioneers within the subject of AI and robotic laboratory partnering.

There’s additionally an ever-growing listing of robotic and cobot distributors, like Turin-based Comau and Stäubli Robotics, Horgen, Switzerland, amongst a dozen others, which can be both shortly adapting current robots for lab work or growing utterly new robots to fulfill the burgeoning wants of Pharma 4.0.

PACK EXPO International 2022

Of course, testing for, discovery, and perfecting any laboratory product doesn’t finish there. Like every other product, it nonetheless must be manufactured, packaged and shipped to clinics and hospitals in want. Pharma 4.0 goes past the lab…and so do the robots and cobots as properly.

PACK EXPO International 2022, which simply concluded in Chicago (October 23-26), had a large 70,000 sq. foot pavilion devoted to life sciences packaging for firms which can be manufacturing prescription drugs, biologics, nutraceuticals, and medical gadgets.

PACK EXPO International 2022, which simply concluded in Chicago (October 23-26), had a large 70,000 sq. foot pavilion devoted to life sciences packaging for firms which can be manufacturing prescription drugs, biologics, nutraceuticals, and medical gadgets.

Stäubli Robotics highlighted its TX2-60 Stericlean robotic for pharmaceutical manufacturing and packaging on the Pack Expo. The Stericlean is a line of robots appropriate for Grade A, B and C environments. The robotic has a totally enclosed construction with customized seals to reduce penetration of airborne particles.

The Stericlean is designed to be versatile for drug supply codecs together with vials, IV baggage, syringes, cartridges, and transdermal gadgets.

And the Stericlean is totally proof against hydrogen peroxide (H2O2) cleansing procedures. With the robotic’s particular joints and enclosed IP65 construction, Stericlean robots are designed to deal with decontamination processes in Vaporized Hydrogen Peroxide (VHP) environments.

Industrial robotic and cobot developer, Comau, can be making a touch for the laboratory market house with the introduction of its Racer- 5 SE (Sensitive Environments). Racer-5 SE is a high-speed industrial robotic transformed “special and sensitive settings” that characterize the pharmaceutical, well being and wonder, meals and beverage and electronics industries.

5 SE (Sensitive Environments). Racer-5 SE is a high-speed industrial robotic transformed “special and sensitive settings” that characterize the pharmaceutical, well being and wonder, meals and beverage and electronics industries.

The Comau lab robotic encompasses a protecting water, warmth and grease-resistant coating, has ruggedized 6-axis articulated robotic arm absolutely that qualifies for IP67 certification (signifies waterproof plus safety in opposition to mud over prolonged time period, high-grade ISO 5 Cleanroom classification (ISO 14644-1), safety from chemical brokers and the necessity to scale back the chance of contamination. It additionally has NSF H1 meals grade lubrication.

Comau says that its Racer-5 SE addresses the particular want for velocity, accuracy and repeatability inside cleanrooms and different delicate environments.

What about people?

Connor W. Coley, assistant professor of chemical engineering at MIT, says advances made in pursuit of the autonomous laboratory reveal the crucial significance of the human factor.

“Humans are always going to set the design objective and specify something that an algorithm can reduce to a numerical optimization,” Coley says. “Humans will always be setting the big-picture goal” by rounds of interrogation.